Compressor for combined screw rod

A compressor and screw technology, applied in the field of combined screw compressors, can solve the problems of high processing cost, high processing difficulty, long processing time, etc., and achieve the effects of high practicability, reduced processing difficulty, and reduced difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

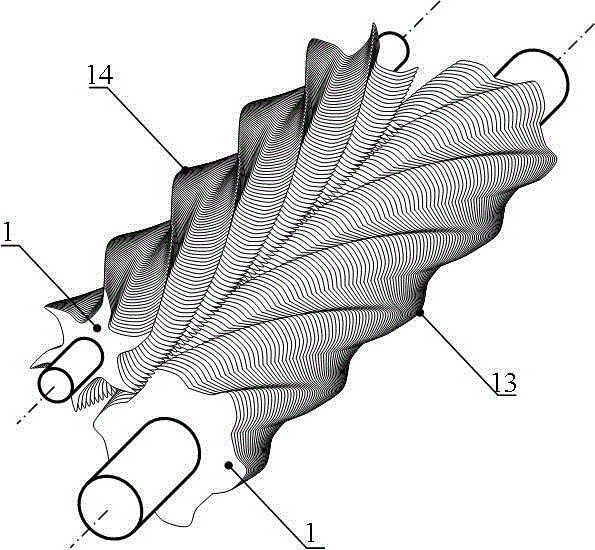

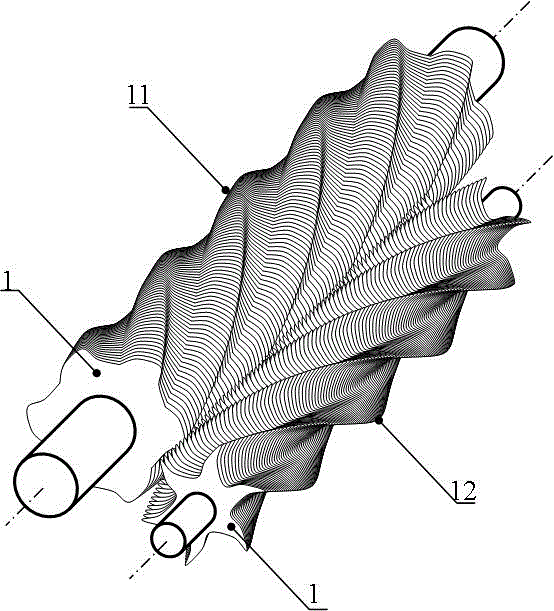

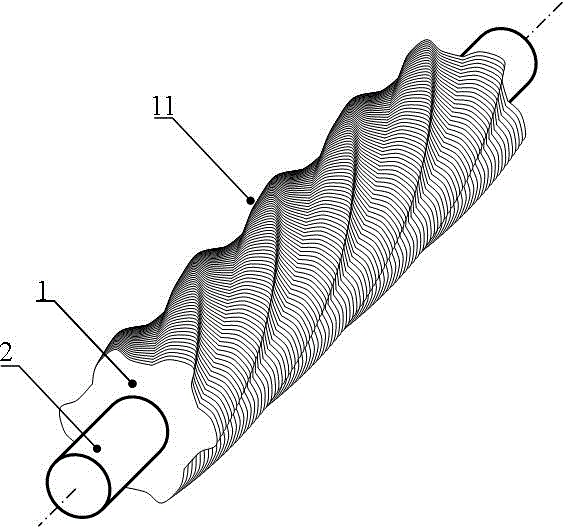

[0051] Example 1: Such as Figure 1 to Figure 15 As shown, the disclosed compressor with a combined screw includes a cylinder with a screw shaft in the cylinder. The screw shaft is a combined screw shaft of thin parts. The screw shaft also includes thin parts 1, shaft 2, and thin parts 1. The outside of the shaft 2 has a tooth bottom engagement part 7 and a tooth top engagement part 8. There is a shaft hole in the sheet part 1, and there is at least one tooth-shaped protrusion in the shaft hole. There is at least one spiral groove on the outside of the shaft 2. The sheet part 1 The number of tooth-shaped protrusions in the shaft hole is the same as the number of the outer spiral grooves of the shaft 2, and they are matched with each other. The outside of the shaft 2 is tightly and orderly sleeved with multiple sheets of parts 1, shaft 2 and multiple sheets The relative position between the parts 1 is fixed, and the gap between the shaft 2 and the multi-sheet parts 1 is filled w...

example 2

[0061] Example 2: Such as Figure 1 to Figure 15 And as shown in Example 1, a compressor with a combined screw is disclosed,

[0062] The glue adopts epoxy resin cement or quick-drying structural glue or metal structural glue.

example 3

[0063] Example 3: Such as Figure 1 to Figure 15 And as shown in Example 1, a compressor with a combined screw is disclosed,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com