Probe sensing method and device based on beam scanning confocal detection technology

A detection technology and beam scanning technology are applied in the field of probe sensing methods and devices based on beam scanning confocal detection technology, which can solve the problems of difficult miniaturization, weak detection light intensity, and low resolution, and achieve easy detection, high-intensity, high-resolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

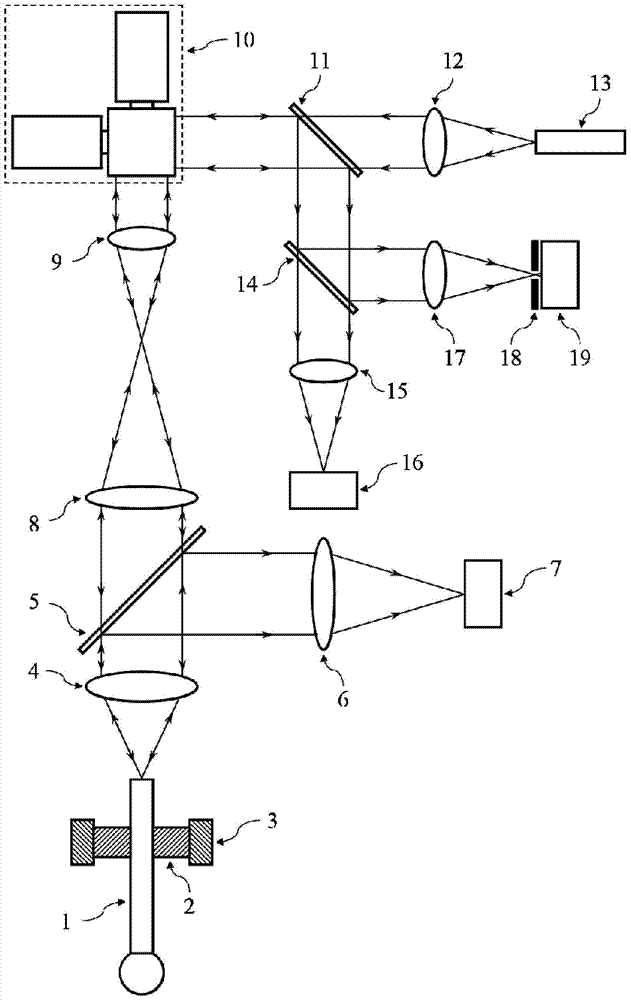

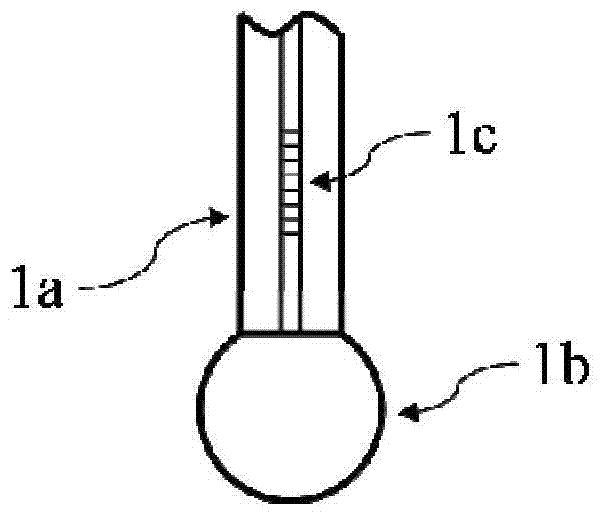

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

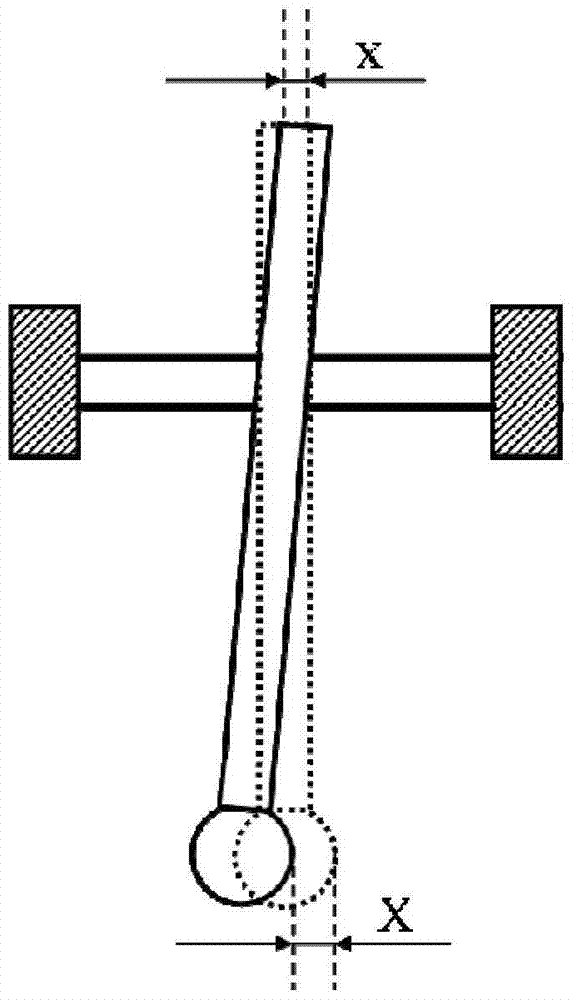

[0026] A probe sensing method based on beam scanning confocal detection technology. The laser beam enters the interior of the fiber probe from the incident end of the fiber probe through the lens. The incident end of the needle emerges, and the output beam of the fiber optic probe is focused to the photodetector through the lens. The transverse photodetector is used to detect the position of the focused spot to measure the transverse displacement of the probe, and the axial photodetector is used to detect the light intensity of the focused spot. To measure the axial displacement of the probe to complete three-dimensional sensing.

[0027] A beam scanning device is used to control the deflection of the laser beam so that the focal point of the laser beam moves along with the fiber probe to ensure that the laser beam can be incident into the fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com