Microscope objective table based on specimen mobile control mechanism

A control mechanism and stage technology, applied in microscopes, optics, instruments, etc., can solve problems such as specimen movement, achieve the effects of reducing dependence, enhancing automatic control functions, and effectively and quickly adjusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

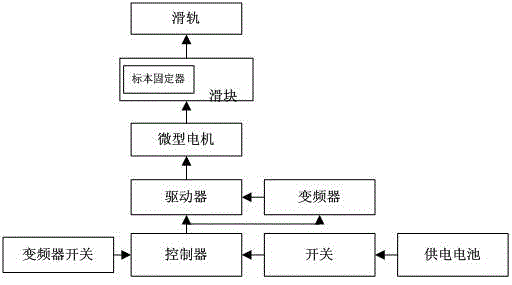

[0025] The microscope stage of this embodiment includes a stage body and a specimen holder set thereon, and also includes a specimen movement control mechanism that includes a power supply battery, a switch, a controller, a driver, a micro motor, The sliding rail and the sliding block, wherein the sliding rail is arranged on the surface of the stage body, the bottom of the sliding block is movably embedded in the sliding rail; the micro motor is fixedly arranged in the sliding block, and the sliding block The surface fixation specimen holder; the power supply battery is connected to the switch, the controller, the driver, and the micro motor in turn; the power supply battery is controlled by the switch to supply power, and the controller is used to control the driver to drive the micro motor to move after being powered; The micro-motor makes the slider move linearly in the slide rail, so that the slider drives the specimen to move linearly; and, the specimen movement control mec...

Embodiment 2

[0028] The difference between the second embodiment and the first embodiment is that the microscope stage includes the stage body and the specimen holder set thereon, and also includes a specimen movement control mechanism, which includes a power supply battery, a switch , A controller, a driver, a micro motor, a sliding rail and a sliding block, wherein the sliding rail is arranged on the surface of the stage body, and the bottom of the sliding block is movably embedded in the sliding rail; and, the switch includes a forward And back two switch buttons. Use forward to control its linear forward movement, and use the back switch to control its linear backward movement.

[0029] Further, the specimen holder is used to clamp the specimen, and in this embodiment, a clip is preferably used, and the clip is fixed to the surface of the slider by a nut. Thus, a clamping structure is formed, which can better fix the specimen. In addition, the clip is an elastic clip, which can improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com