Control method and system of material loading and refuelling device

A control method and control system technology, applied in the direction of electrical program control, program control in sequence/logic controller, etc., can solve problems such as inability to perform automatic operation, lack of system recording process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Such as Figures 1 to 4 As shown, the present invention provides a control method for loading and refueling equipment, including:

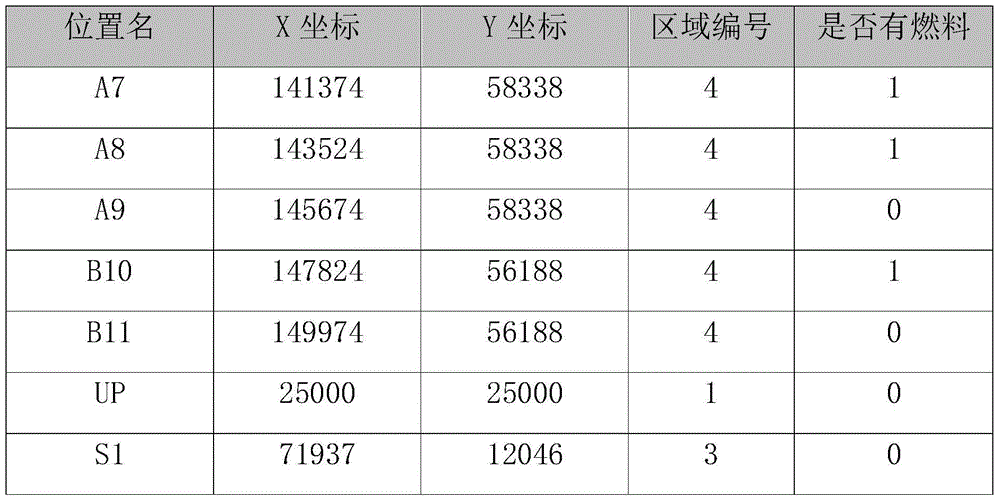

[0043] Step S1, acquiring the first data, the first data includes: the position information of the arrangement of the fuel assemblies in the core and the spent fuel pool; here, respectively for the arrangement of the fuel assemblies in the core and the spent fuel pool, establish Corresponding fuel assembly arrangement location table, hereinafter referred to as the location table, such as figure 1 As shown, the table reflects the location information of the fuel assembly arrangement in the core or the spent fuel pool;

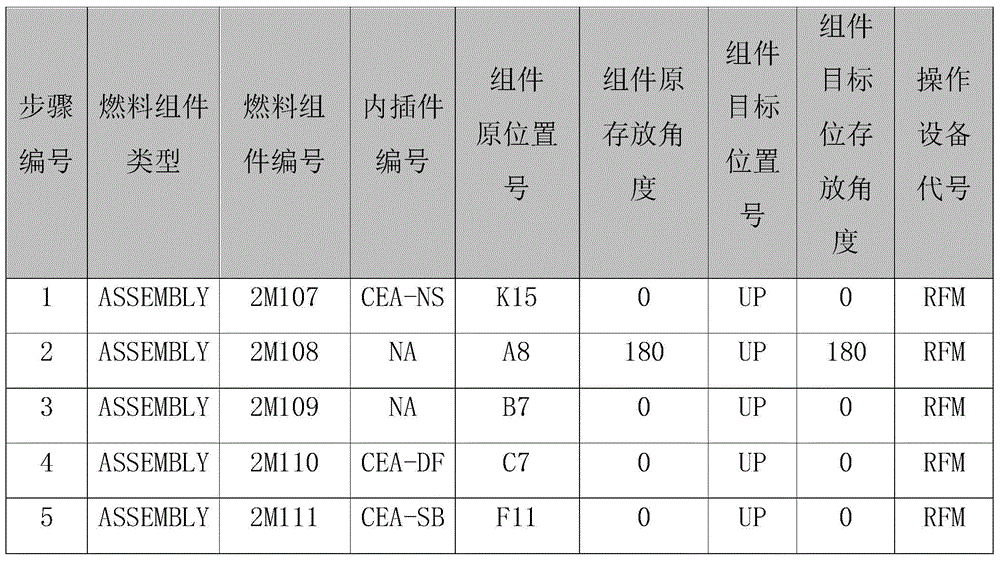

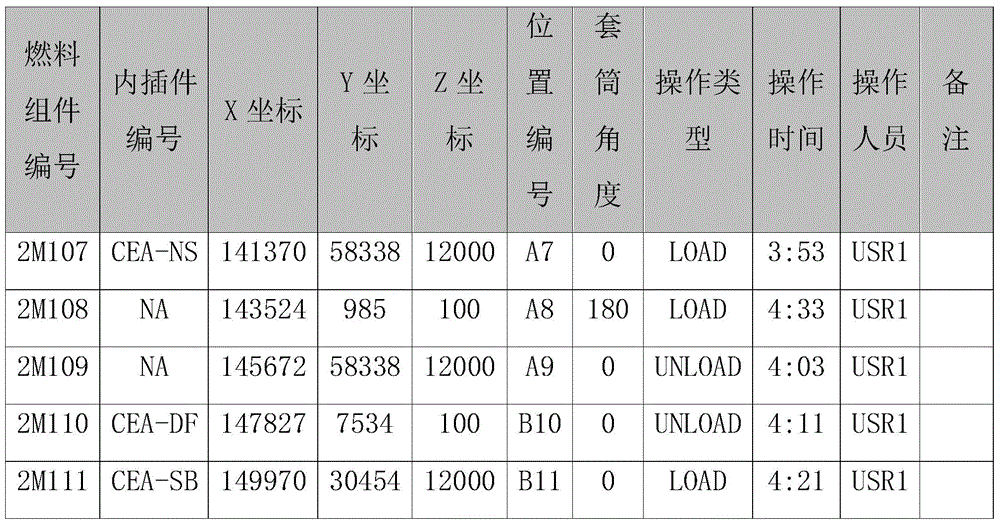

[0044] Step S2, obtaining second data, the second data including: the movement sequence requirements for loading and unloading fuel assemblies of each refueling equipment; here, for the step sequence of loading and unloading fuel assemblies of each refueling equipment, establish the corresponding fuel The component loading ...

Embodiment 2

[0054] Such as Figures 1 to 4 As shown, the present invention also provides another control system for refueling equipment, the first module is used to obtain the first data, the first data includes: the position information of the fuel assembly arrangement in the core and the spent fuel pool ;

[0055] The second module is used to acquire second data, and the second data includes: the movement sequence requirements for loading and unloading fuel assemblies of each refueling equipment;

[0056] The third module is used to acquire the third data, the third data includes: the moving process of the fuel assembly performed by the refueling equipment;

[0057] The fourth module is used to obtain the fourth data, the fourth data includes: abnormal conditions that occur during the fuel assembly loading and unloading process;

[0058] The fifth module is used for controlling the refueling equipment according to the first to fourth data.

[0059] Preferably, the location informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com