An electret capacitive ultrasonic sensor and its manufacturing method

A technology of ultrasonic sensor and manufacturing method, which is applied in the direction of electret electrostatic transducers, sensors, electrical components, etc., can solve the problems of difficult chip integration of drive circuits, unfavorable wide application of sensors, high DC voltage, etc., and achieve ultra-low power low power consumption, simplification of peripheral configuration circuits, and ultra-low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

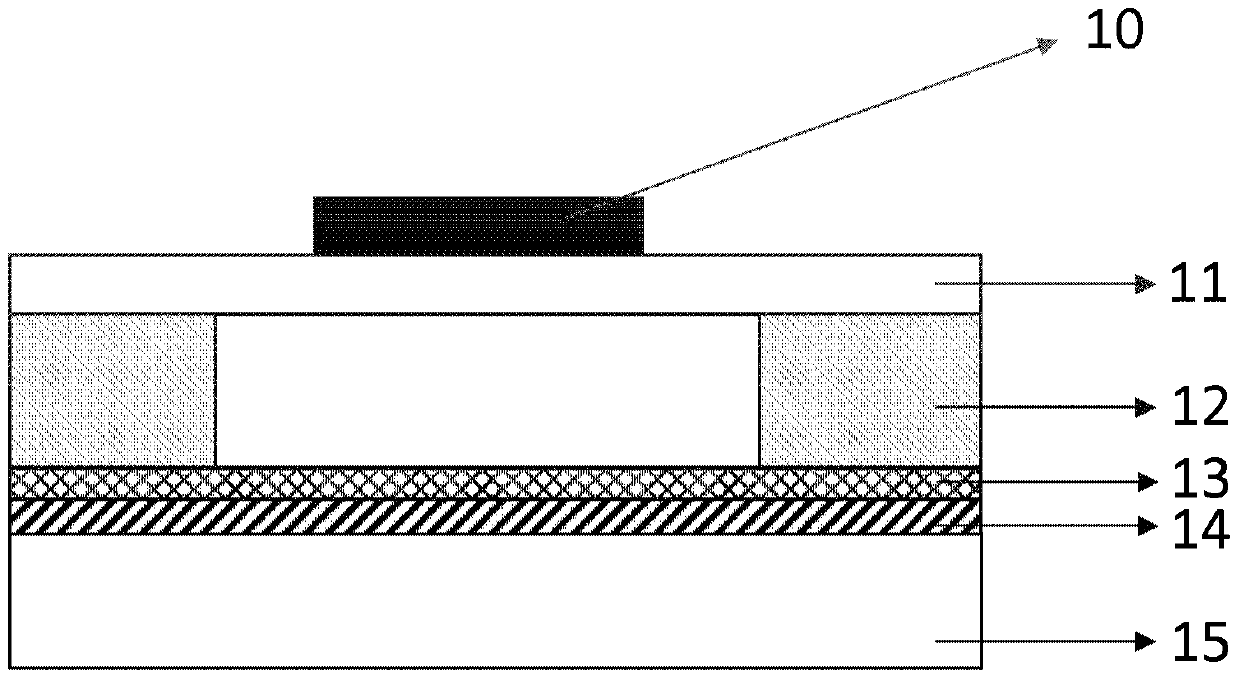

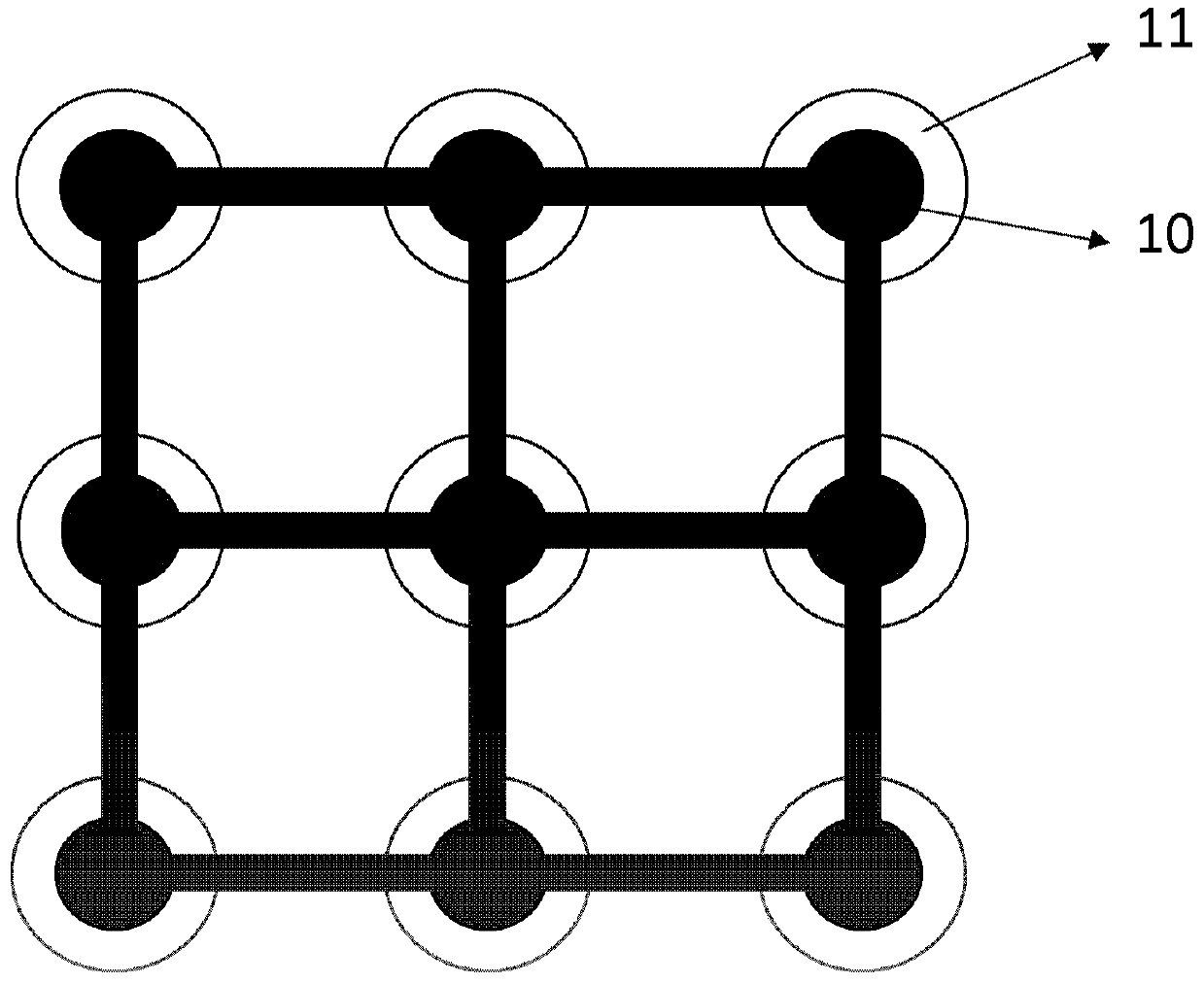

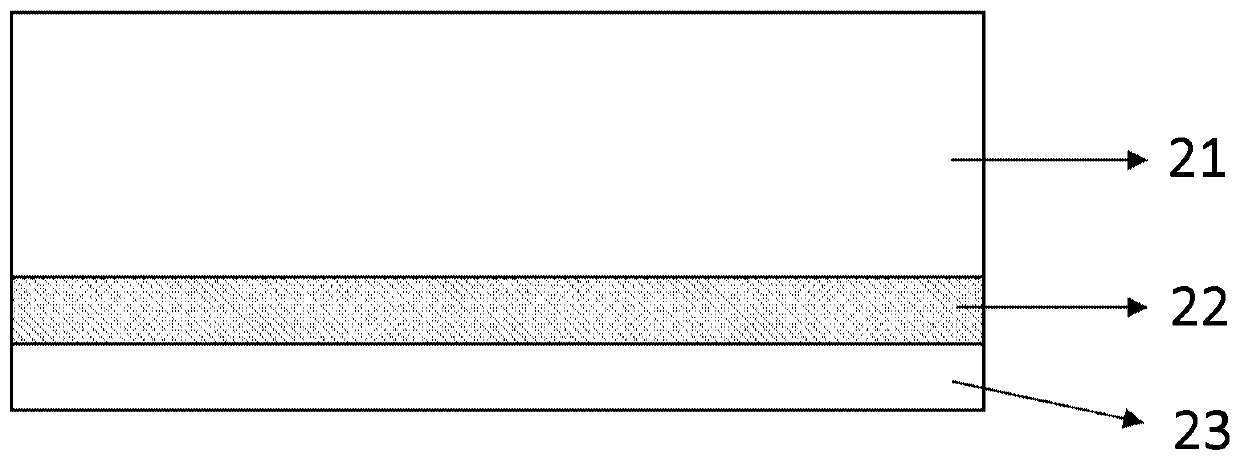

[0025] Electret materials refer to functional dielectric materials with long-term storage of polarization and space charge capabilities, including polymer-based organic electrets and SiO-based 2 of inorganic electrets. The present invention utilizes the electret material and silicon chip bonding technology to prepare capacitive ultrasonic sensors. The capacitive ultrasonic sensor of the present invention comprises a low-resistance substrate, deposits an electret material on the substrate, and adopts a corona method to prepare an electret layer; adopts PECVD or other processes to deposit an insulating layer on the electret layer; A support layer is deposited on the support layer, and circular or other shaped cavities are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com