Covering harrows for cultivation ridges of sugarcane

A technology of covering soil harrows and cultivating ridges, which is applied in the field of preparation of agricultural machinery and equipment, can solve the problems of high labor intensity, time-consuming and laborious, and low work efficiency, and achieve the effects of improving work efficiency, broad market prospects, and scientific structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail now in conjunction with accompanying drawing:

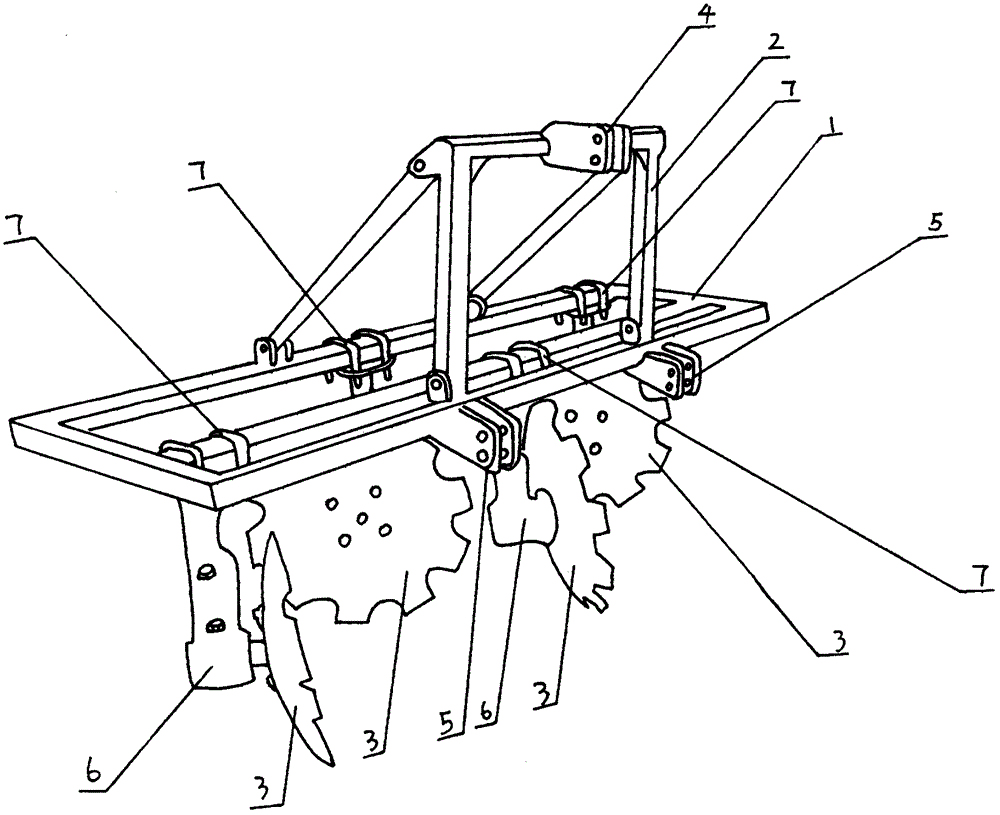

[0018] What Fig. 1 showed is the structural representation of the present invention. The present invention is mainly made up of frame body (1), elevating frame (2), four covering soil harrows (3); Two connection sleeves one (4); the shape of the lifting frame (2) is a tripod, which is placed on the top of the frame body (1), and the upper part of the lifting frame (2) is provided with a connection sleeve two (5) ; Four soil-covering rakes (3) are placed on the bottom of the frame body (1), and each soil-covering rake (3) is fixed by a frame (6), and each frame (6) is It is fixed on the support body (1) by the collar (7), and forms a soil-covering combination by two soil-covering rakes (3) simultaneously.

[0019] Application principle of the present invention:

[0020] During the operation of the device, the two connection sleeves one (4) provided on the frame body (1) and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com