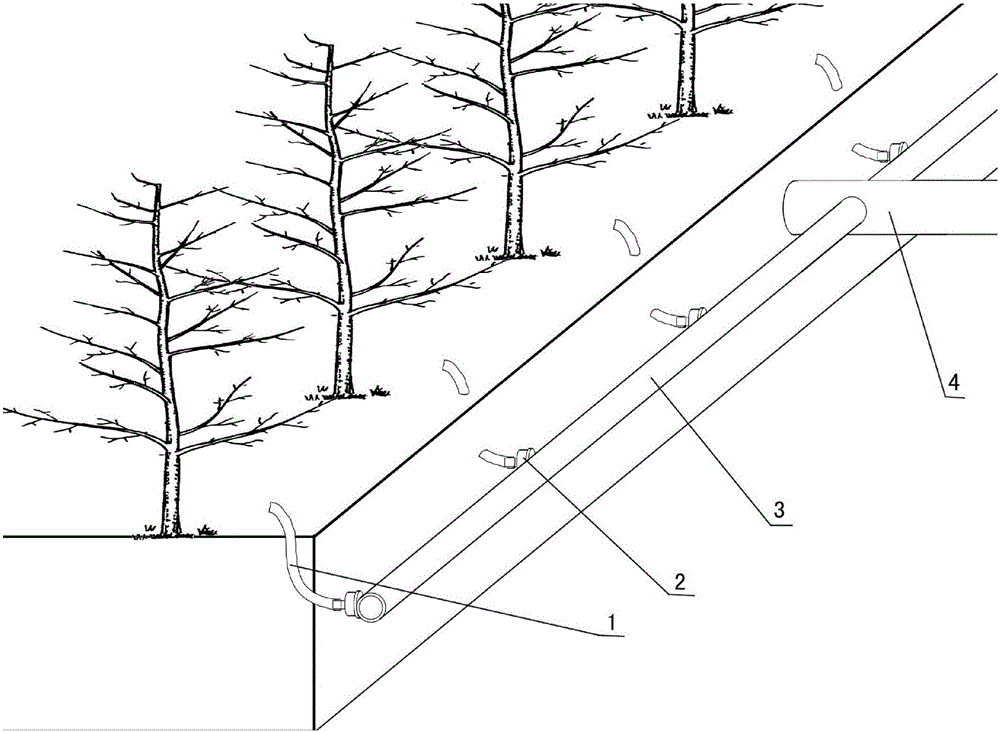

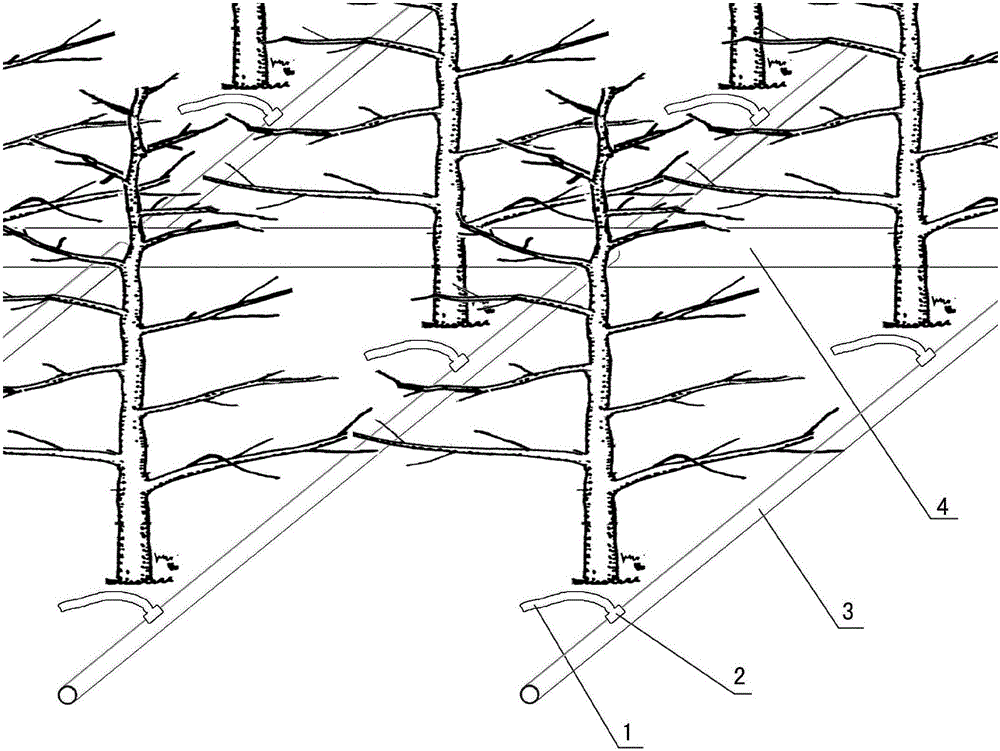

Arrangement composition of orchard pipe outflor irrigation system terminal

A small tube outflow and irrigation system technology, applied in horticulture, watering devices, botanical equipment and methods, etc., can solve the problems of easy aging, deterioration and damage, increased replacement probability, and difficult emptying of capillary water, so as to reduce Frost heave damage probability at low temperature, not easy to aging, deterioration and damage, and convenient for mechanized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

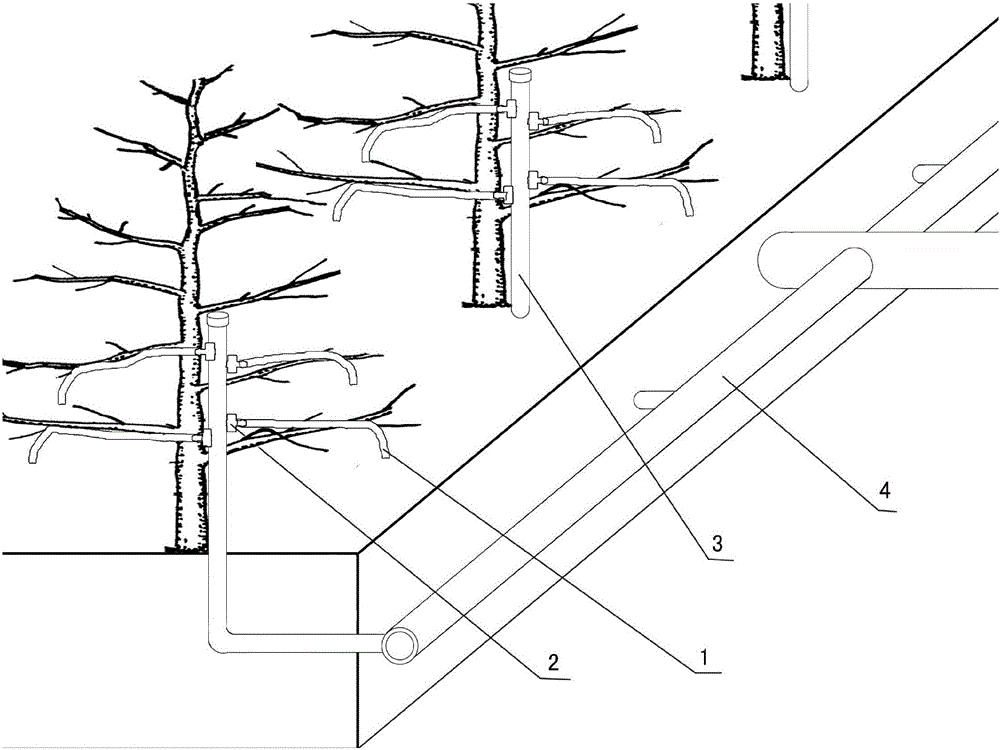

[0038] Such as image 3 As shown, the capillary 3 of the arrangement structure of the orchard small pipe outflow irrigation system terminal is buried 30-50 cm underground, and one end of the capillary 3 is connected to the underground main pipe through the underground branch pipe 4. The side 5-10 cm protrudes from the ground and extends vertically upwards along the trunk of the fruit tree. The capillary 3 after protruding from the ground is tied with the trunk of the fruit tree with a rope. The height of the capillary 3 is not higher than the height of the fruit tree. The top of the capillary 3 is folded Closed, at different heights of the capillary 3, that is, where the main branch grows, an effective number of small shunt tubes 1 are connected radially on the capillary 3, and the water outlet is opened at the end of the small shunt tube 1, between the small shunt tube 1 and the branches of the fruit tree. Secure with tie rope. Each shunt tubule 1 and capillary tube 3 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com