Bearing buffering bottom mounting sliding rail

A bottom support and bearing technology, applied in furniture parts, home appliances, drawers, etc., can solve the problems of no buffering effect, high noise, low cost and other problems of the bottom support slide rail, and achieve simple and convenient installation, reduce impact force, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

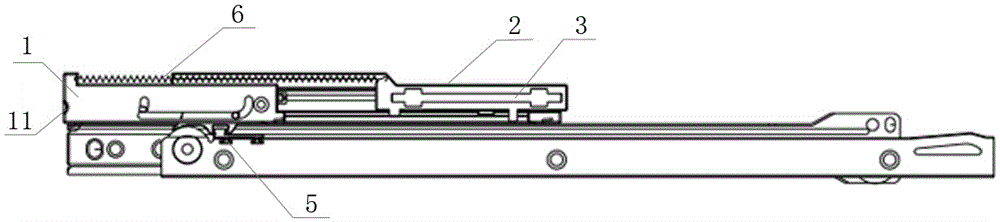

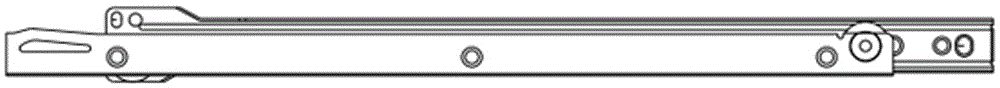

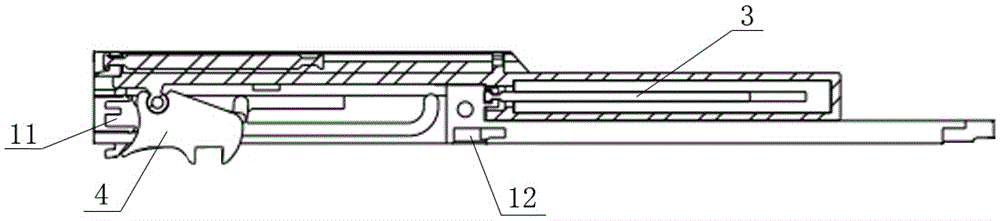

[0023] As shown in the accompanying drawings, a bearing buffer bottom slide rail includes two sets of fixed rails and movable rails matched with each other, a pulley 10 and a guide groove 8 matched with the pulley, and the guide groove 8 is arranged on the fixed rail bottom. The two sets of fixed rails and movable rails are respectively matching fixed rail Ⅰ and movable rail Ⅰ, fixed rail Ⅱ and movable rail Ⅱ. There is a buffer, and the buffer includes a bracket I1, a bracket II2, a damper 3 and a clutch device. The bracket I1 and the bracket II2 are matched and connected into one body, and a pair of buckles 9 are arranged on the top of the fixed rail I. The bottom of the bracket I is provided with a slot 12 matching the buckle, and the buffer and the fixed rail are connected to the slot 12 through the buckle 9 . The clutch device includes a clutch assembly I4 and a clutch assembly II5, the clutch assembly I4 is arranged at the lower part of one side of the bracket I1, the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com