Mechanical continuous pneumatic fire extinguishing cannon

A continuous and mechanical technology, applied in fire rescue and other fields, can solve the problems of inconvenient use, difficult to carry, large space occupation, etc., and achieve the effect of convenient disassembly, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

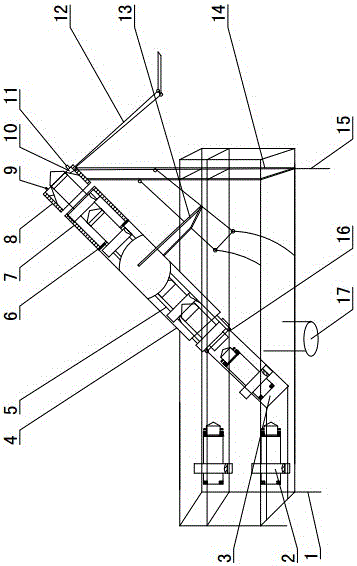

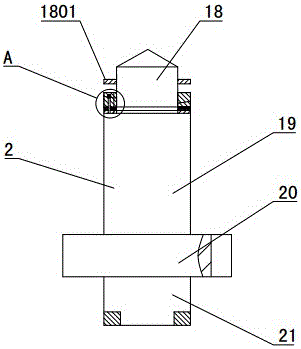

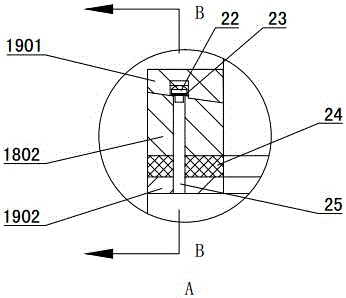

[0038] Such as figure 1 Shown: the mechanical continuous type pneumatic fire extinguishing gun includes a barrel and a fire extinguishing shell 2, and one end of the barrel is rotatably mounted on the frame 1. Frame 1 comprises upper and lower two layers, and the upper layer is used for placing shell and gun barrel, and the lower floor is used for placing shell conveying device and power unit. The gun barrel has a rotating and separating unit that drives the high-pressure launching cylinder 19 and the fire-extinguishing bullet 18 to rotate relatively, so that the high-pressure launching cylinder 19 and the fire-extinguishing bullet 18 are relatively rotated and then the clamping mechanism is separated to realize firing.

[0039] The shell delivery device includes a shell transporter 3 and a guide barrel 4 . The shell carrier 3 is installed on the left side of the frame 1 lower floor, and the outlet end of the guide barrel 4 communicates with the inlet end of the barrel. Fram...

Embodiment 2

[0073] The difference between embodiment 2 and embodiment 1 is that the rotating barrel 7 is coaxially provided with gears, the output shaft of the gearbox is provided with gears, and the motor drives the rotating barrel 7 to rotate through gear transmission. The motor is a servo motor, and the motor is connected with a PLC controller, and the firing speed of the fire-extinguishing shells 2 and the firing interval of two adjacent fire-extinguishing shells 2 are adjusted by the PLC controller.

Embodiment 3

[0075] The difference between embodiment 3 and embodiment 1 is: the guide barrel 4 and the shell transporter 3 are installed on the ground, and when fire extinguishing is required, they are assembled on site, which takes up little space and is convenient for transportation.

[0076] Fire extinguishing materials such as dry powder can also be adorned in the fire-extinguishing warhead 18, and motor can also be speed-regulating motor, and the output shaft of motor is provided with straight pin, is used for driving rotating gun barrel 7 and rotates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com