A Method of Controllable Evaporation Surface Temperature Based on Porous Composite Materials

A porous composite material and evaporation surface technology, which is applied in the field of controllable evaporation surface temperature based on porous composite materials, can solve the problems of low energy conversion efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of gold nanoparticles

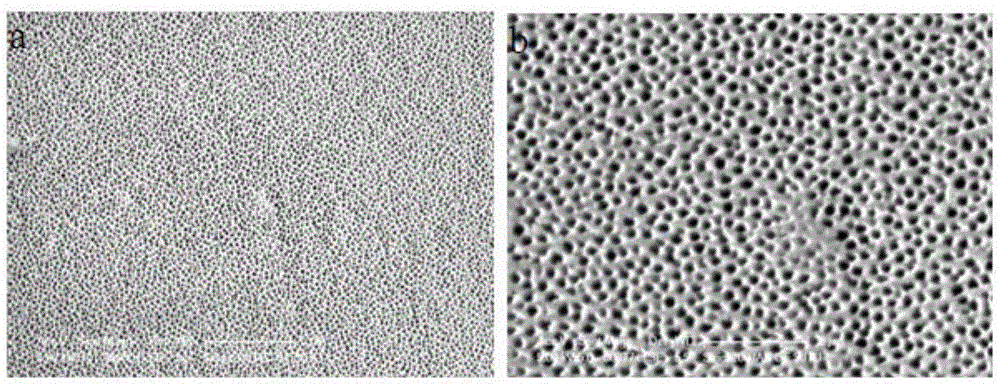

[0024] Add chloroauric acid (HAuCl 4 ) solution, chloroauric acid (HAuCl 4 ) solution has been prepared in proportion according to the formula, after the mixed solution is evenly stirred, add the prepared trisodium citrate solution, stir while heating for 20 minutes, then cool at room temperature and continue to stir for 15 minutes to obtain a particle size of 10nm gold nanoparticles. The obtained gold particle solution is used as a seed, and a certain proportion of hydroxylamine hydrochloride solution and chloroauric acid solution are repeatedly introduced to make the gold nanoparticles grow gradually. The particle size of gold nanoparticles can be grown from 10nm to about 100nm. After the growth is complete, let the gold nanoparticles settle, and the gold nanoparticles are electromagnetic wave absorbing particles, that is, light-to-heat conversion particles.

[0025] (2) Preparation of double-layer composite membrane

[002...

Embodiment 2

[0032] (1) Preparation of gold nanoparticles: same as in Example 1.

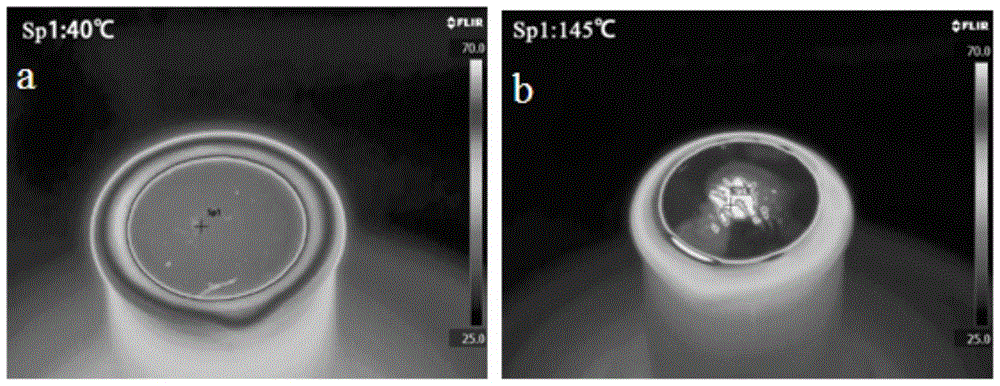

[0033] (2) Preparation of carbon film: the material with electromagnetic wave absorption characteristics is carbon; the preparation of electromagnetic wave absorption structure film is the same as example 1: in ethanol (weight concentration 0.1%-20%), will have the microscopic wave absorption characteristics Nanostructured carbon is evenly dispersed in ethanol, and a carbon film is prepared on the surface of a porous anodized aluminum filter membrane by suction filtration.

[0034] Such as Figure 4 As shown, under the same irradiation conditions, the average surface temperature of the carbon film is 102.9°C, while the average surface temperature of the gold film is 95.1°C. It can be seen that the use of different absorbing materials can also control the surface temperature.

Embodiment 3

[0036] (1) Preparation of gold nanoparticles: same as Example 1, but only 10nm particles need to be prepared.

[0037] (2) Preparation of paper-based composite membrane: use the gold nanoparticle concentrate obtained as described in (1), dilute it 3 times, take about 30mL solution, pour it into a beaker with cut dust-free paper at the bottom, put Put it in a desiccator with formic acid atmosphere. After about 12 hours, the supernatant liquid below the liquid surface was carefully removed, so that the surface self-assembled particle film was deposited on the paper fiber; then the composite film was taken out and dried.

[0038] (3) The modification of the paper-based composite membrane is the same as in Example 1, but no plasma cleaning is used.

[0039] (4) The evaporation conditions of the paper-based composite film are the same as in Example 1.

[0040] The surface temperature of the paper-based composite film during evaporation is as follows: Figure 5 shown. Its averag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com