Inorganic material for treating waste water containing cesium, strontium and cobalt and preparation method thereof

A technology of inorganic materials and wastewater, applied in chemical instruments and methods, other chemical processes, nuclear engineering and other directions, can solve problems such as affecting the curing effect, and achieve the effects of easy solid-liquid separation, high radiation stability, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

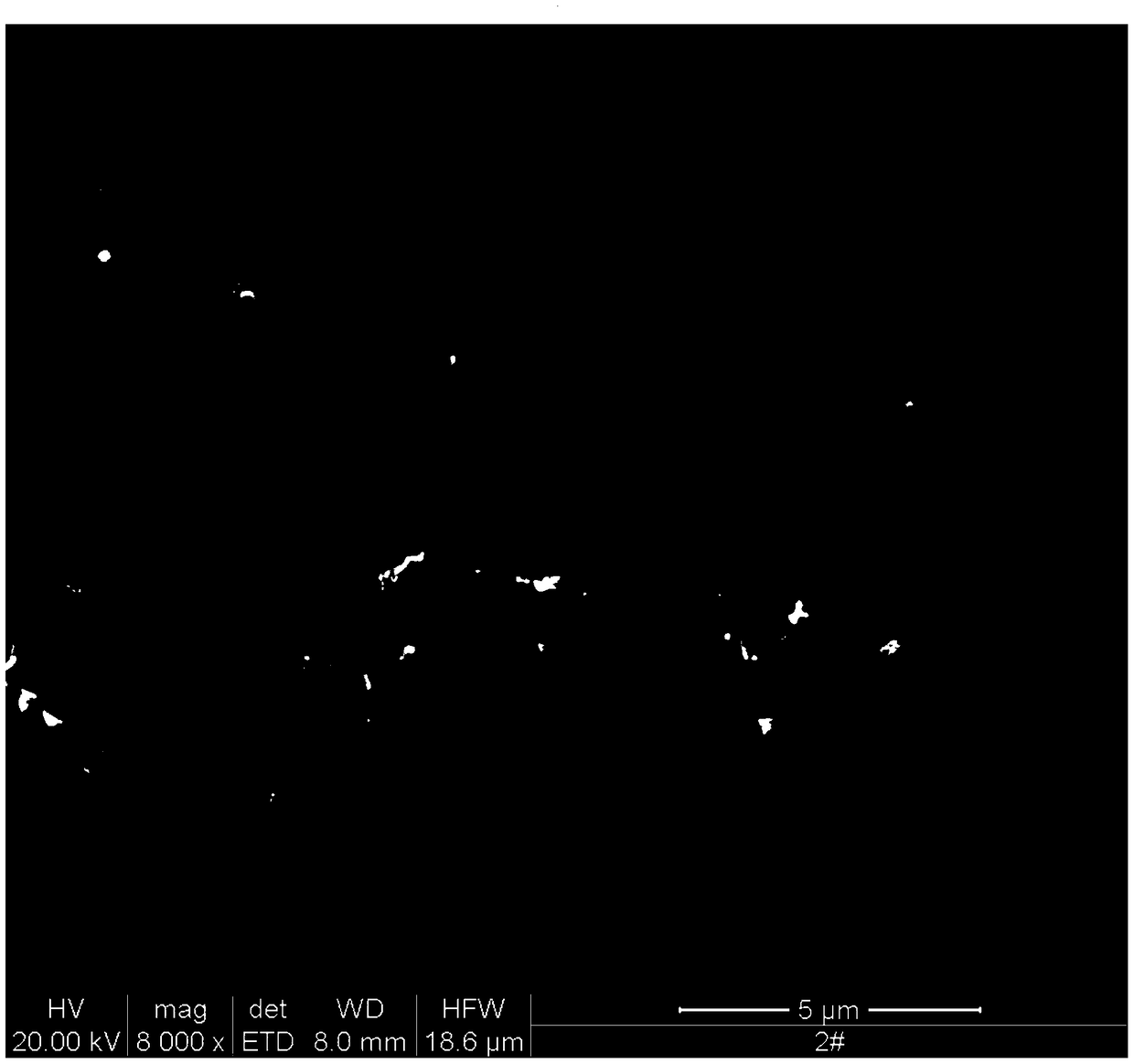

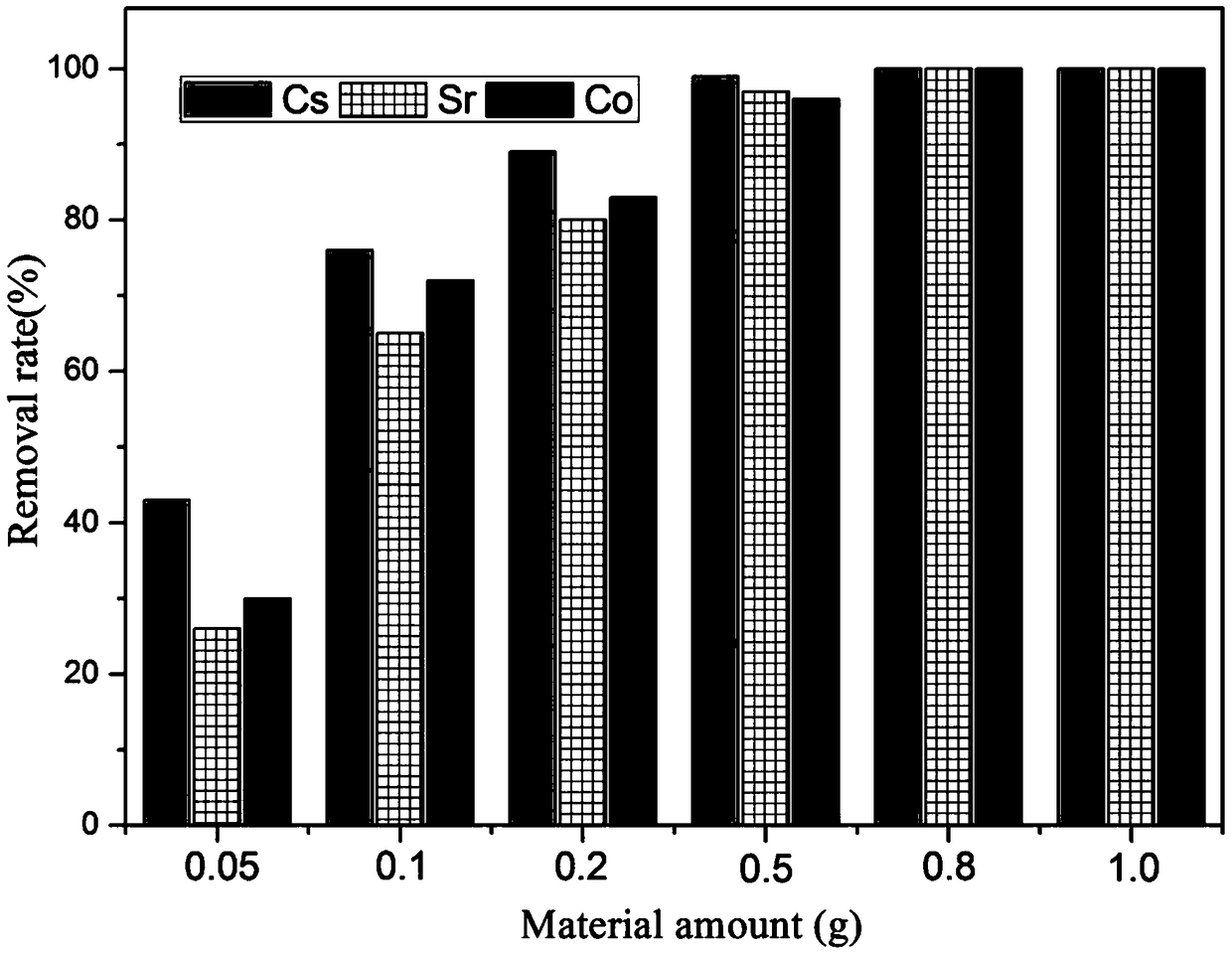

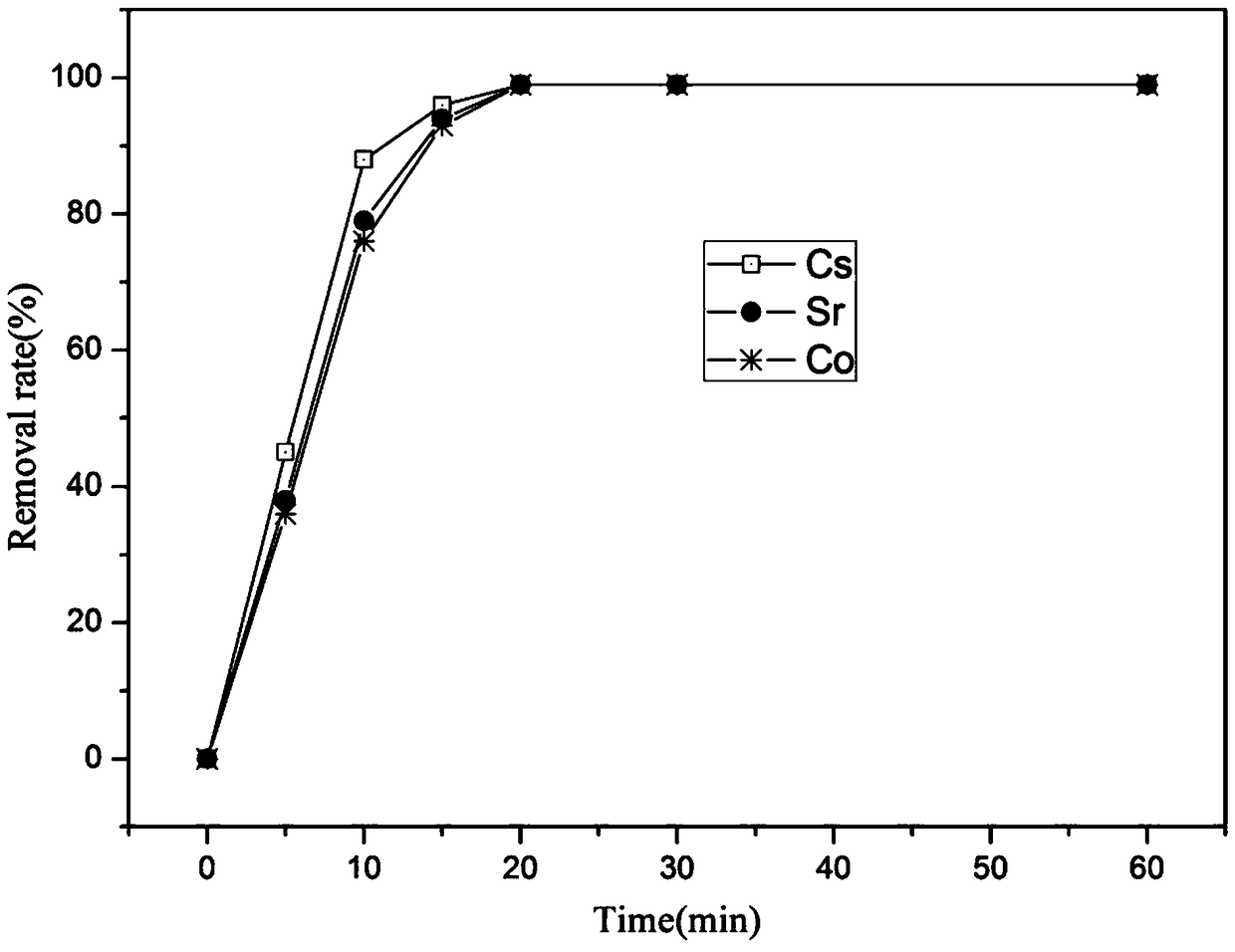

Image

Examples

preparation example Construction

[0029] In addition, the present invention also proposes a method for preparing an inorganic composite adsorbent for treating trace amounts of cesium, strontium, and cobalt ions in nuclear power plant radioactive waste water, the steps are as follows:

[0030] a. Mix potassium pyrophosphate solution with a concentration of 0.1-1.0mol / L with sodium metavanadate or sodium silicate solution or sodium molybdate solution with a concentration of 0.1-1.0mol / L in a certain proportion, and the mixing process is continuous carried out with stirring;

[0031] b. Use hydrochloric acid to adjust the pH value of the reaction solution to 1-4 with hydrochloric acid, then slowly add 0.1-1.0 mol / L zirconium oxychloride solution dropwise to form a precipitate, and stir fully at the same time to complete the reaction . When the precipitate is no longer formed, use acid or alkali to adjust the pH value of the mixture to a constant value, and after standing for 6 to 12 hours, carry out suction filt...

Embodiment 1

[0035]Specifically, in this embodiment, 0.5 mol / L potassium pyrophosphate solution can be mixed with 0.5 mol / L sodium metavanadate acid solution at a molar ratio of 5:1 under continuous stirring. And use 10% hydrochloric acid to adjust the pH value of the reaction solution to an acidic value of 3.0, slowly add 1.0mol / L zirconium oxychloride solution dropwise with a separatory funnel to generate a precipitate, the molar ratio of zirconium oxychloride to sodium metavanadate is 1 : 1, while fully stirring to complete the reaction. When the precipitate is no longer formed, the pH value of the solution is adjusted to 1.0 with acid or alkali, and after standing for 6 hours, suction filtration is performed until the filtrate is close to neutral. Then it was washed with deionized water until neutral, dried at 40°C and ground into powder to obtain zirconium pyrophosphovanadate.

[0036] Then, the prepared zirconium pyrophosphovanadate is mixed with 60% by mass fraction and 0.15 mol / L ...

Embodiment 2

[0039] Specifically, in this embodiment, 0.1 mol / L potassium pyrophosphate solution may be mixed with 1 mol / L sodium metavanadate acid solution at a molar ratio of 10:1 under continuous stirring. And use 10% hydrochloric acid to adjust the pH value of the reaction solution to an acidic value of 4.0, slowly add 1.0mol / L zirconium oxychloride solution dropwise with a separatory funnel to generate a precipitate, the molar ratio of zirconium oxychloride to sodium metavanadate is 1 : 1, while fully stirring to complete the reaction. When the precipitate is no longer formed, the pH value of the solution is adjusted to 1.0 with acid or alkali, and after standing for 12 hours, suction filtration is performed until the filtrate is close to neutral. Then it was washed with deionized water until neutral, dried at 60° C. and ground into powder to obtain zirconium pyrophosphovanadate.

[0040] Then, the prepared zirconium pyrophosphovanadate is mixed with 60% by mass fraction and 0.2mol / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com