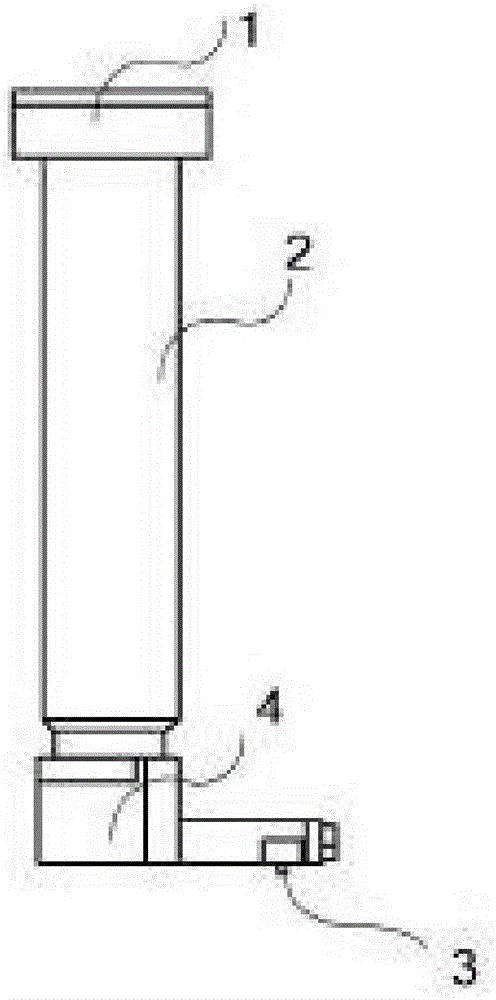

Frame-sealing-glue coating nozzle and frame-sealing-glue coating device

A coating device and sealing glue technology, which is applied to the surface coating liquid device, spraying device, coating, etc., can solve the problems of glue throwing, sealing glue dripping, product failure, etc., to improve accuracy , improve the yield of products, and avoid the effect of plastic rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to avoid the phenomenon of glue rejection in the frame sealing glue coating process and improve the product yield, the embodiment of the present invention provides a frame sealing glue coating nozzle and a frame sealing glue coating device. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

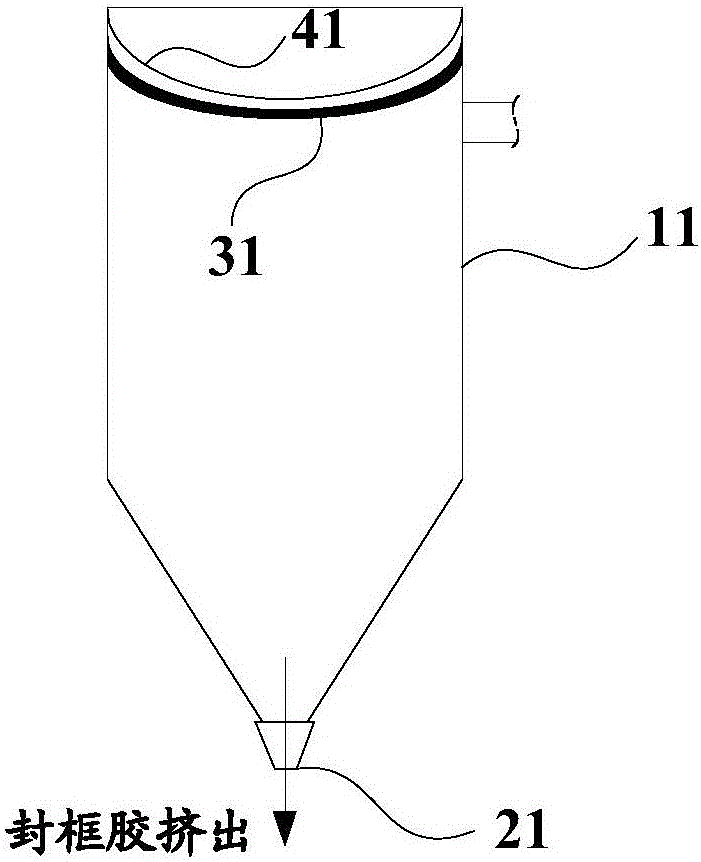

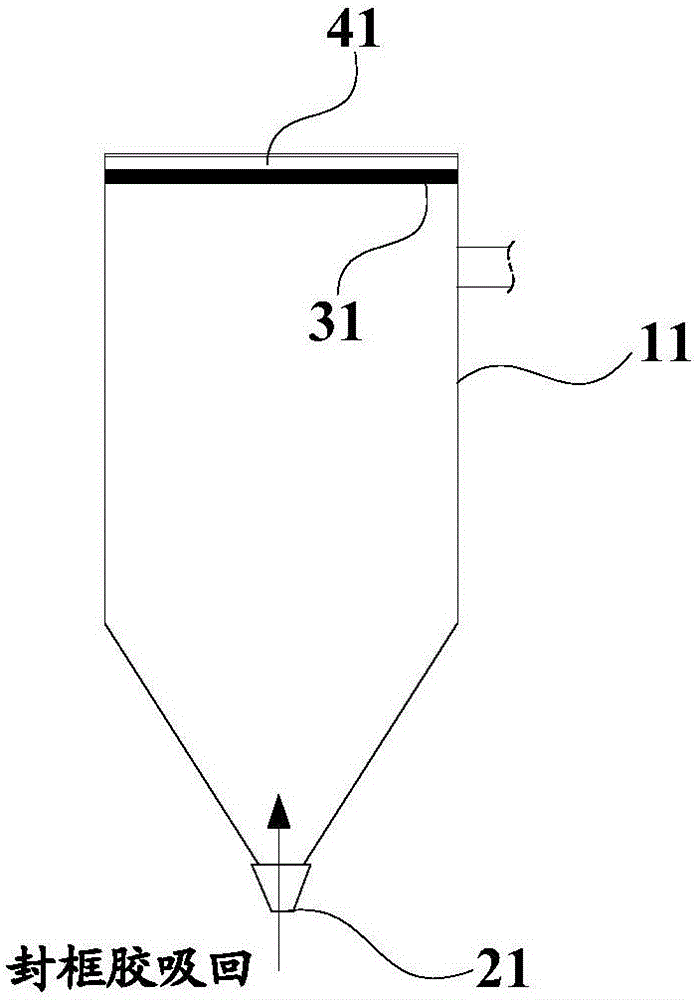

[0045]The frame sealing adhesive coating nozzle provided by the embodiment of the present invention includes a nozzle chamber, a mouth communicating with the nozzle chamber, a telescopic inner film located in the nozzle chamber, and a driving device for driving the telescopic inner film to deform in the nozzle chamber. The film reduces the volume of the nozzle cavity in the first deformation state, extrudes the sealing glue in the nozzle cavity through the mouth, and the stretchable inner film increases the volume of the nozzle cavity in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com