Welding tool for welding rack plate of pile of drilling platform and semicircular pipes

A technology for drilling platform legs and welding tooling, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems affecting the production cycle of the main chord, shorten the production cycle, improve the production efficiency, and improve the The effect of the support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

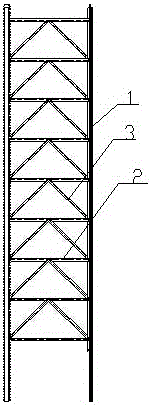

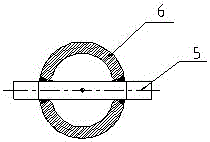

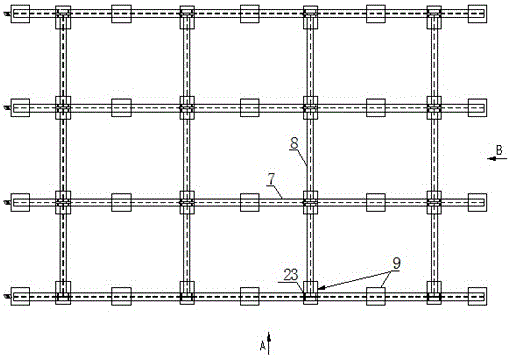

[0024] Such as Figures 3 to 5 As shown, the present invention discloses a welding tool for the rack plate and the semicircular pipe 6 in the pile leg of the drilling platform, including the platform and the snap ring 15 for fixing the rack plate 5 and the semicircular pipe 6. 7 is welded with the longitudinal H-shaped steel 8, wherein the lower end surface of the horizontal H-shaped steel 7 is evenly distributed along the long axis direction with a number of supporting legs 9, and the upper end surface of the longitudinal H-shaped steel 8 is evenly distributed along the long axis direction. The rack plate fixing seat 23 of the plate 5; the rack plate 5 is arranged along the long axis direction of the longitudinal H-shaped steel 8 and supported in the rack plate fixing seat 23 on the upper end surface of the longitudinal H-shaped steel 8;

[0025] Such as Figure 6 and Figure 7 As shown, the rack plate fixing seat 23 includes a clamping plate 10 and a reinforcing bracket 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com