Pre-warning system of numerical control machine tool

A technology of CNC machine tools and early warning systems, applied in metal processing machinery parts, maintenance and safety accessories, measuring/indicating equipment, etc., can solve problems such as electrical component damage, mains overcurrent, phase loss, short circuit unknown, etc., to achieve failure small loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

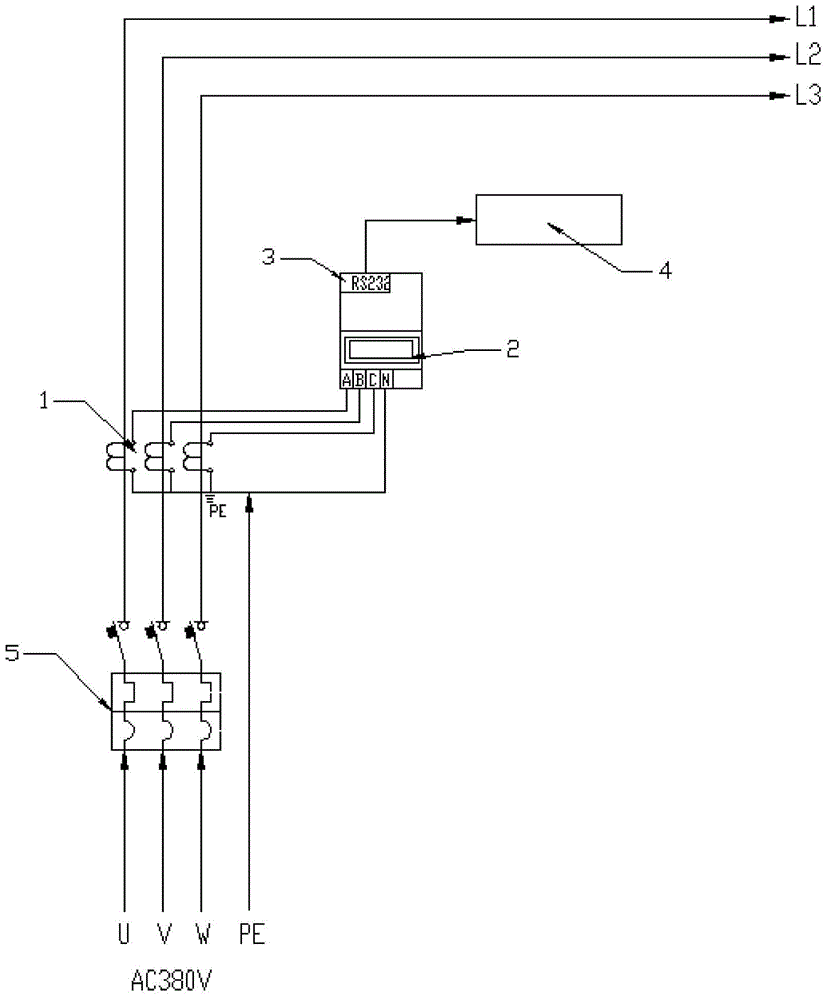

[0016] The specific implementation process of the present invention will be described in detail below with reference to the accompanying drawings.

[0017] An early warning system for CNC machine tools, such as figure 1 As shown, it includes a detection element, a collection and judgment element, and a signal output element; the detection element is installed on the main line of the CNC machine tool circuit through the main power switch 5 to detect the main line current, and the collection and judgment element judges what the detection element detects When the current is greater than or less than the rated current threshold, an early warning signal is issued through the signal output element. The early warning signal may be an acoustic or optical alarm device, such as a flashing red light, a buzzer, etc.

[0018] Specifically, the detection element is a current transformer 1, and the current transformer 1 is installed on the main line through a main power switch 5 to detect current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com