Automatic edge grinding device for finished wood floor product

A technology for wood floors and finished products is applied in the field of automatic wood floor finished product edging devices, which can solve problems such as affecting the appearance of wood floors, rough cutting edges, etc., and achieve the effects of good popularization, reasonable technology and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

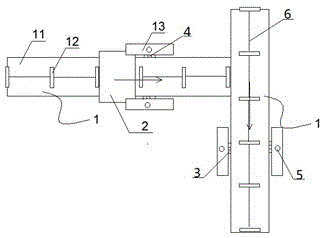

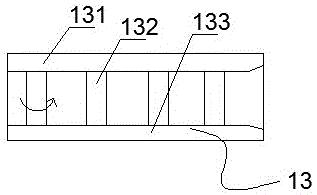

[0015] like Figure 1-2 As shown, the embodiment of the present invention provides an automatic wooden floor finished edging device, including two grinding units 1, wherein one grinding unit 1 is located below the other grinding unit 1 and is perpendicular to each other. The unit 1 is located at the end of the upper grinding unit 1, the grinding unit 1 includes a roller 14 and a conveyor belt 11 wound on the roller 14, the conveyor belt 11 is provided with a first chute 6, the first slide There are several vertical baffles 12 distributed in the groove 6 through the sliders with servo devices. The baffles 12 are formed by socketing of several cubes and are scalable. The two sides of the conveyor belt 11 are symmetrically equipped with two grinding devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com