Bending machine

A technology of pre-bending and plastic pipes, which is applied in the field of plastic pipe bending machines, can solve the problems of difficult removal and low bending efficiency, and achieve the effect of high product forming rate and improved bending precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

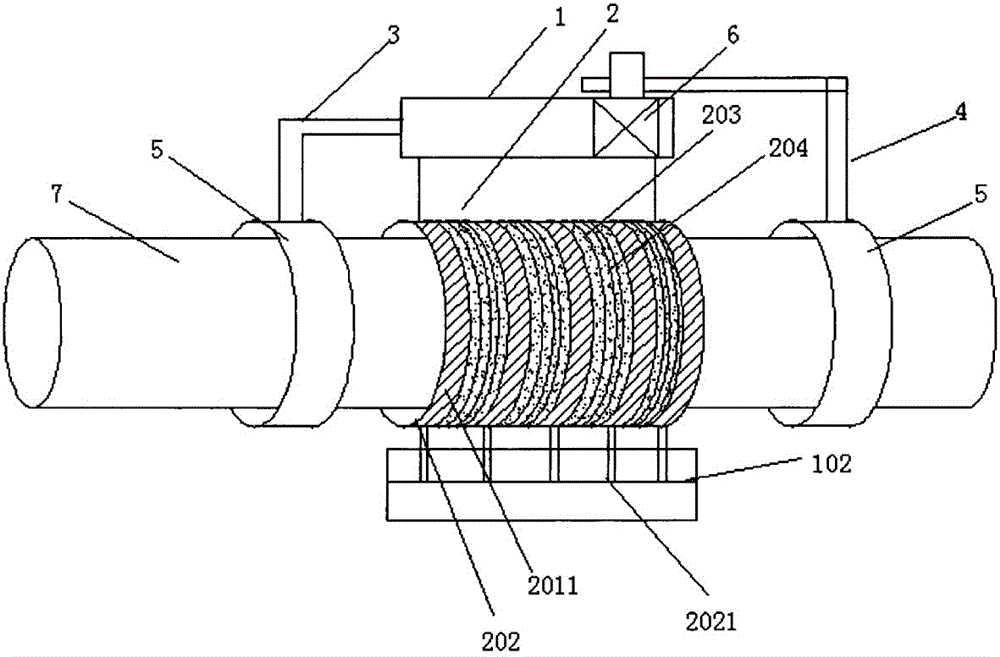

[0011] like figure 1 As shown, the plastic pipe bending machine of the present invention includes a workbench 1 and a mold or a wheel mold 2, and is characterized in that: the lower end of the mold or wheel mold 2 is arranged on the lower end of the workbench 1, and the workbench 1 is close to the mold or wheel mold. One side of the wheel mold 2 is provided with a buffer block 101, which is used as a supporting curved surface when the mold or the wheel mold is bent. The mold or wheel mold 2 is composed of a plurality of sets of heating coils 201, each set of electromagnetic heating coils is provided with a corresponding fixing sleeve 202, a distance is provided between a plurality of fixing sleeves, and aluminum foil is arranged between adjacent fixing sleeves. The strips 203 are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com