Quick-opening and quick-closing pressing beam hasp-type feeding and discharging device

A technology of discharging device and pressing beam, applied in the direction of clamping device, packaging, transportation and packaging, etc., can solve the problems of easy existence of sliding wire, cumbersome operation, complicated operation, etc., to improve reliability and stability, and improve the production process. Simple, simple production process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

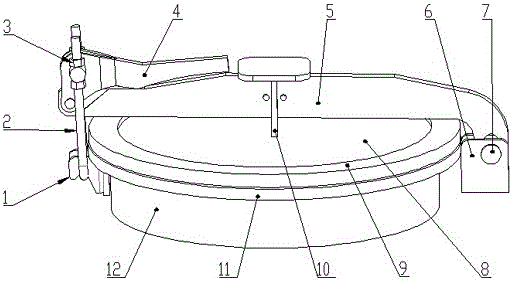

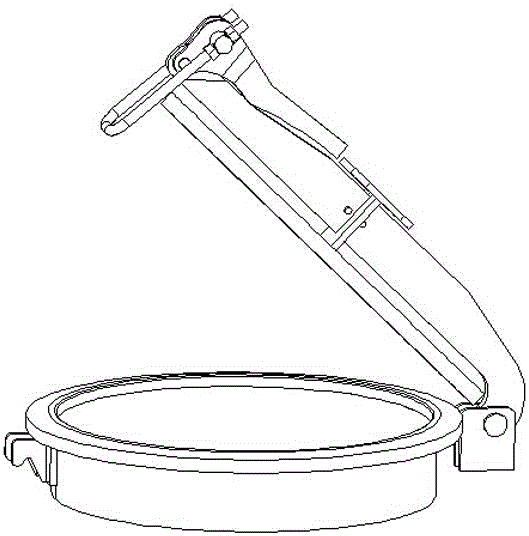

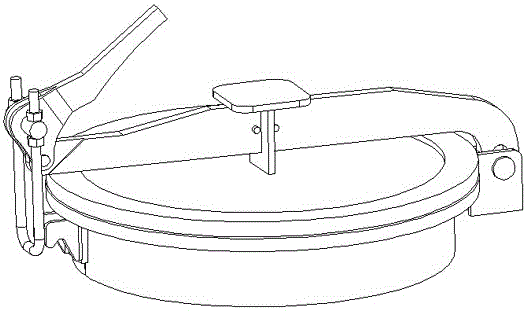

[0021] Figure 1 ~ Figure 3 It is a preferred mode of the present invention, which shows a quick-opening and quick-closing pressure beam buckle-type feeding and discharging device, including: a buckle locking block 1, a buckle U-shaped buckle 2, a buckle adjustment nut 3, a buckle Buckle handle 4, pressure beam 5, pressure beam bracket 6, pressure beam rotation pin 7, feed opening sealing plate 8, U-shaped sealing ring 9, sealing plate support 10, feed opening flange 11, and feed opening joint 12. It is characterized in that: the material port flange 11 and the material port joint 12 are welded to each other, and the diameter of the material port joint 12 is smaller than the diameter of the material port flange 11; the lower part of the material port sealing plate 8 is equipped with a U-shaped seal circle 9; the pressure beam 5 is L-shaped and fixed on the upper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com