Electromechanical interlocking control method for safe scram of escalator

An electromechanical interlocking, escalator technology, applied in escalators, transportation and packaging, etc., can solve problems such as personal safety accidents, and achieve the effect of direct and effective safety emergency stop method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

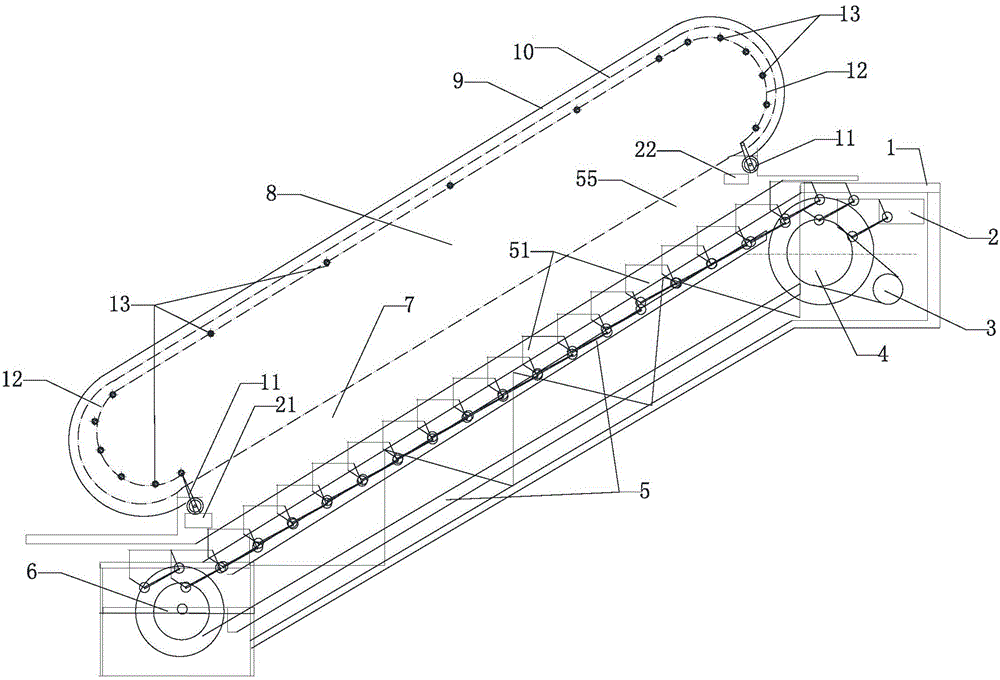

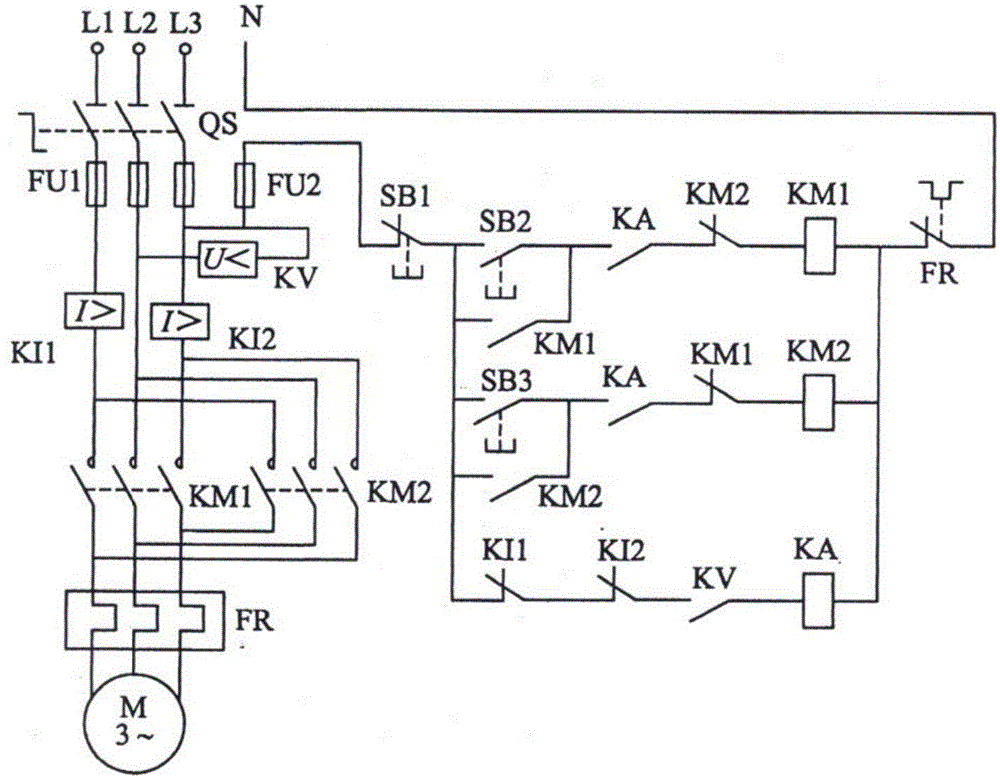

[0021] Embodiment one, electromechanical interlock control method, by figure 1 , 4 Description, it is characterized in that: in the control box 2 of the electric drive system installed on the steel structure truss of the elevator, in the overload protection circuit of the electrical control circuit, a control circuit emergency stop button switch SB1 circuit line is directly connected in series. 11 circuit wires (SB11) of the pull-rope switch, and the SB11 wiring circuit in the pull-rope switch 11 is normally closed, so that the pull-rope switch SB11 and the emergency stop button switch SB1 in the overload protection circuit play an electromechanical double safety protection role, and The original thermal relay FR plays the role of electromechanical multiple safety protection; when the elevator fails, anyone on or around the elevator can pull the pull rope 12 set on the hand support safety plate in time, so that the electric control circuit SB11 circuit of the pull rope switch ...

Embodiment approach 2

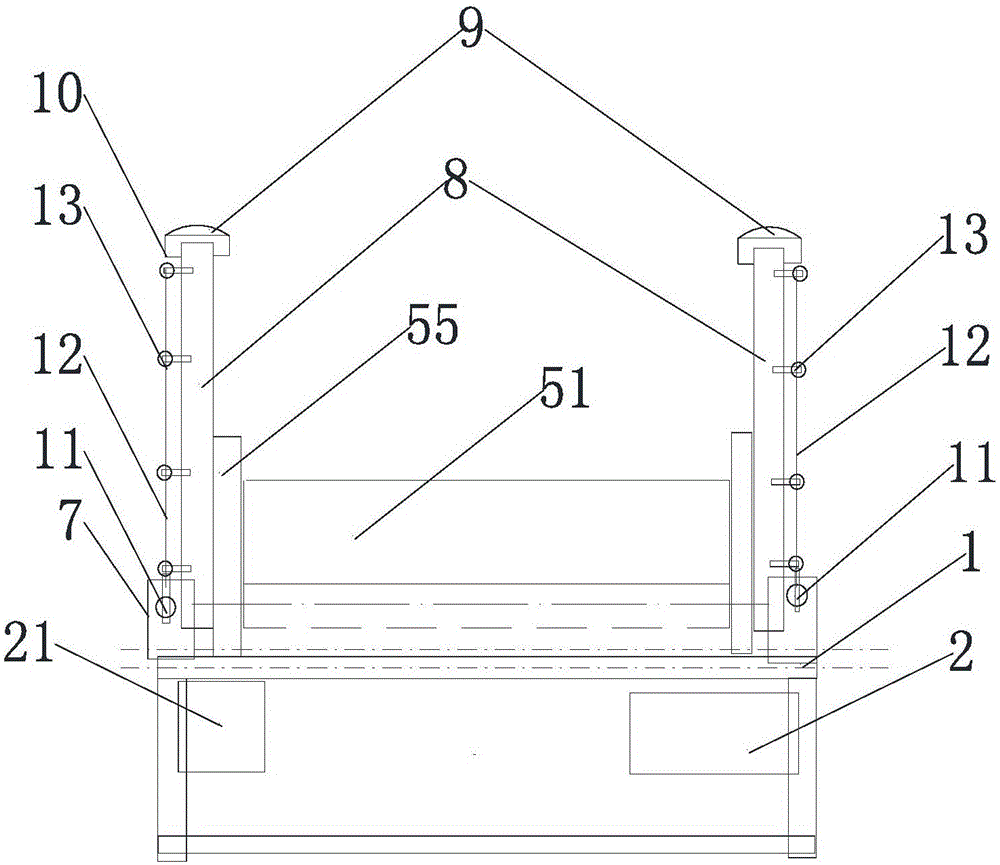

[0022] Embodiment 2, electromechanical interlock control method, by figure 2 , 4 Description, it is characterized in that: the pull rope switch 11 is fixed at the end of the steel structure truss of the elevator, and the control circuit line emergency stop button switch 21 (SB1) in the power control box 2 is connected with the pull rope switch 11. The normally closed circuit line SB11 is connected in series. When an accident occurs, it is not necessary for the personnel on the elevator to squat dangerously or bend over to press the emergency stop button switch 21 arranged on the inner guard plate 55 below the entrance and exit of the escalator. Anyone on the elevator can pull the pull rope 12 at any time to start the pull rope switch 11 to control the circuit SB11 to cut off the fault, so that the KM1 or KM2 normally closed contacts connected in series in the main circuit are disconnected, and the traction motor M running in an emergency stop is realized. The elevator stops ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com