Multifunctional working hanging basket for railway tunnel

A multi-functional and operational technology, applied in railway inspection vehicles, hoisting devices, cranes, etc., can solve problems such as inability to achieve, difficult position adjustment, lack of flexibility, etc., to save costs, improve work efficiency and construction safety, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

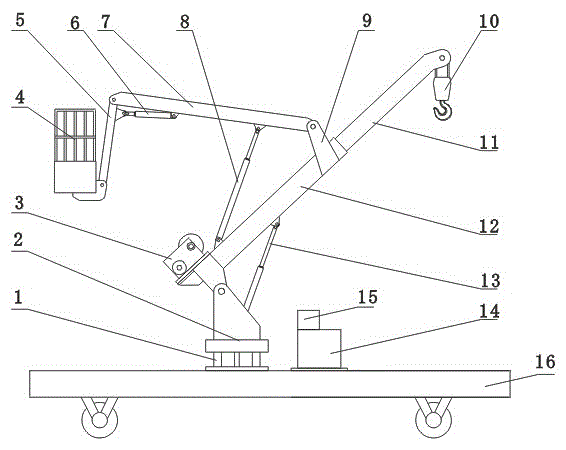

[0028] Such as figure 1 As shown, the railway tunnel multifunctional operation basket includes a track flat car 16, and also includes a base 1,

[0029] Rotary table 2, hoisting device 3, hydraulic system 14, electric control operating device 15, main control oil cylinder 13, operating machine boom 12, working machine

[0030] Owner arm 7, secondary arm cylinder 6, secondary arm 5, working basket 4 and working arm cylinder 8;

[0031] The base 1, the hydraulic system 14, and the electric control operating device 15 are fixed on the rail platform car 16 by bolts; the rotating table 2 capable of rotating 180 degrees is connected to the base 1 through bearings, and the rear end of the working machine arm 12 is connected to the rotating table 2. The lifting device 3 is fixed on the rear end of the working machine boom 12;

[0032] A retractable telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com