Crank arm type aerial work platform

A high-altitude work platform, articulated arm technology, applied in the direction of lifting device, etc., can solve the problems of small adjustment range, large tilting and shaking range of the platform, inflexible use, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

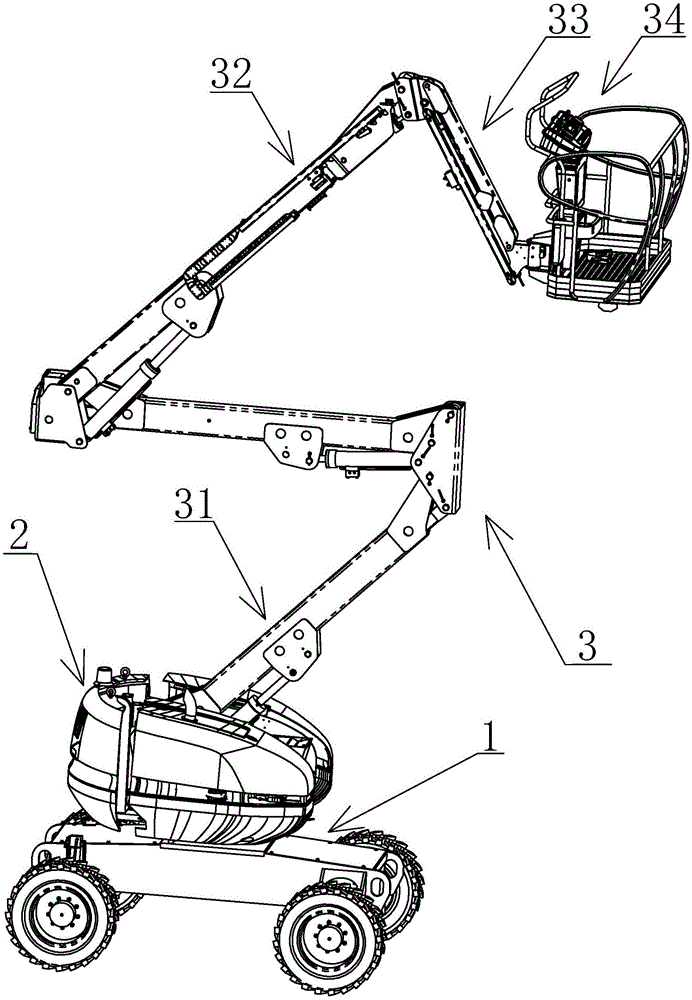

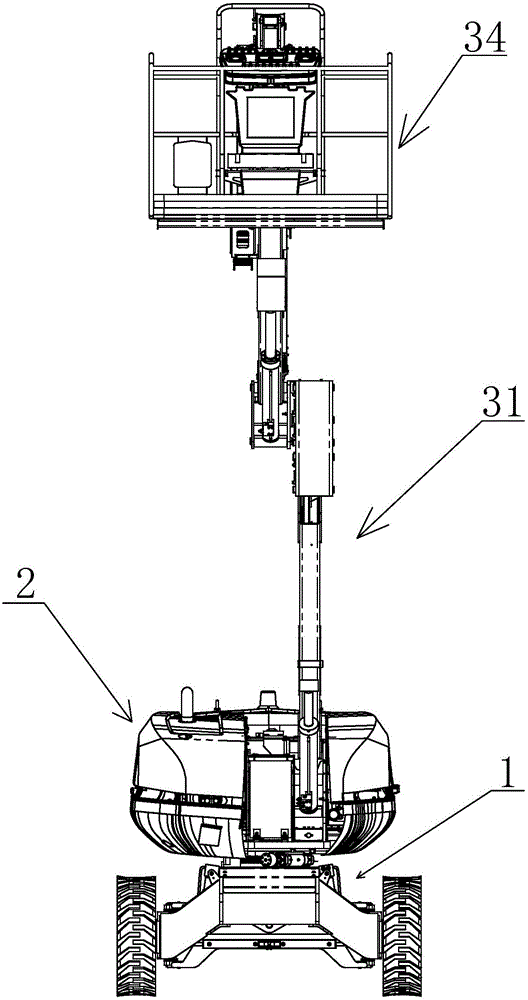

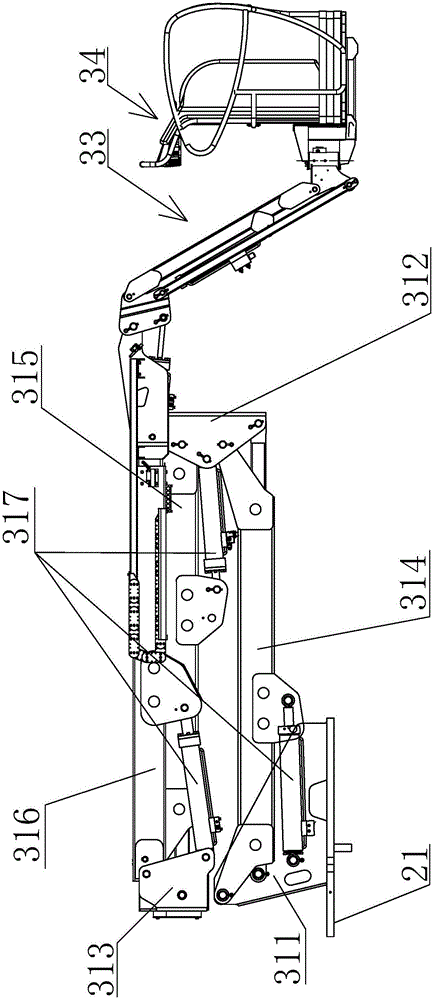

[0028] Such as Figure 1-Figure 13A crank-arm type aerial work platform shown includes a traveling chassis 1, a driving device 2 and a lifting device 3. The traveling chassis 1 includes a fixed crossbeam 11 equipped with four wheels, and the upper end surface of the fixed crossbeam 11 is rotatably connected to There is a gear plate 24, the upper end surface of the gear plate 24 is fixed to the bottom of the fixed plate 21 of the driving device 2, and the upper end surface of the fixed beam 11 is also fixed with a driving screw 22 through the fixing seat 23, and the driving screw 22 is connected to the The gear plate 24 is meshed; the lifting device 3 includes a lifting arm assembly and a working platform 34, and the lifting arm assembly includes a folding arm assembly 31, a telescopic arm assembly 32 and a four-link leveling arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com