Method for making Baijiu through yellow wine lees

A technology for yellow distiller's grains and white wine, applied in the field of winemaking, can solve the problems of inability to realize recycling, high cost of waste dregs treatment, and no one to buy waste dregs, and achieve the effects of shortening fermentation time, speeding up fermentation, and reducing material flying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

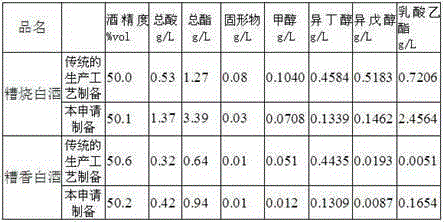

Examples

Embodiment 1

[0020] The method that present embodiment 1 makes white wine with rice distiller's grains, comprises the following steps:

[0021] (1) Preparation of rice wine Lactobacillus culture medium: After diluting with rice wine and water to an alcohol content of 13.0 volL, add 1.0% yeast extract juice, add 0.2% soluble starch, and insert the sterilized culture medium made by culturing at 28°C for 2 days;

[0022] (2) Preparation of the yeast culture of Paenopsis echinosporium: cultured on wort juice plus agar solid medium at 28°C for 1 day;

[0023] (3) Evenly mix the culture solution of Lactobacillus rice wine and the yeast culture of N. cystis into the cage chaff;

[0024] (4) Evenly add the milled grains and the cage bran in step (3) to the yellow rice wine grains, and at the same time add 1.0% of the grains after the first distillation and 0.5% of malt powder;

[0025] (5) Quickly move the distiller's grains in step (4) into a fermenter for distiller's grains, and ferment at 25°...

Embodiment 2

[0028] The method that present embodiment 2 makes white wine with rice distiller's grains, comprises the following steps:

[0029] (1) Preparation of the culture medium of Lactobacillus of rice wine: After diluting with rice wine and water to an alcohol content of 15.5 volL, add 2.0% yeast extract, add 0.8% soluble starch, and insert the sterilized culture medium made by culturing at 30°C for 5 days;

[0030] (2) Preparation of the yeast culture of Paenopsis echinosporium: cultured on wort juice plus agar solid medium at 33°C for 3 days;

[0031] (3) Evenly mix the culture solution of Lactobacillus rice wine and the yeast culture of N. cystis into the cage chaff;

[0032] (4) Evenly add the milled grains and the cage bran in step (3) to the rice wine grains, and at the same time add 5.0% of the grains after the first distillation and 3.0% of malt powder;

[0033] (5) Quickly move the yellow rice distiller's grains in step (4) into the yellow rice wine grains fermentation tan...

Embodiment 3

[0036] The method that present embodiment 3 makes white wine with rice distiller's grains, comprises the following steps:

[0037] (1) Preparation of the culture medium of Lactobacillus of rice wine: After diluting with rice wine and water to an alcohol content of 14.2 volL, add 1.5% yeast extract, add 0.5% soluble starch, and insert the sterilized culture medium made by culturing at 29°C for 3.5 days;

[0038] (2) Preparation of yeast culture of Paenispocystis cystis: cultured on wort juice plus agar solid medium at 30.5°C for 2 days;

[0039] (3) Evenly mix the culture solution of Lactobacillus rice wine and the yeast culture of N. cystis into the cage chaff;

[0040] (4) Evenly add the milled grains and the cage bran in step (3) to the rice wine grains, and add 2.5% of the grains after the first distillation and 2.0% of malt powder at the same time;

[0041] (5) Quickly move the distiller's grains in step (4) into a fermenter for distiller's grains, and ferment at 30°C fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap