A Method of Connecting Graphite and Molybdenum Using Thermal Diffusion Technology

A technology of thermal diffusion and technology, which is applied in the field of connecting graphite and molybdenum by thermal diffusion technology, can solve the problems of complex process and difficult control of connection parameters, and achieve the effects of simple preparation process, saving precious metal resources, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

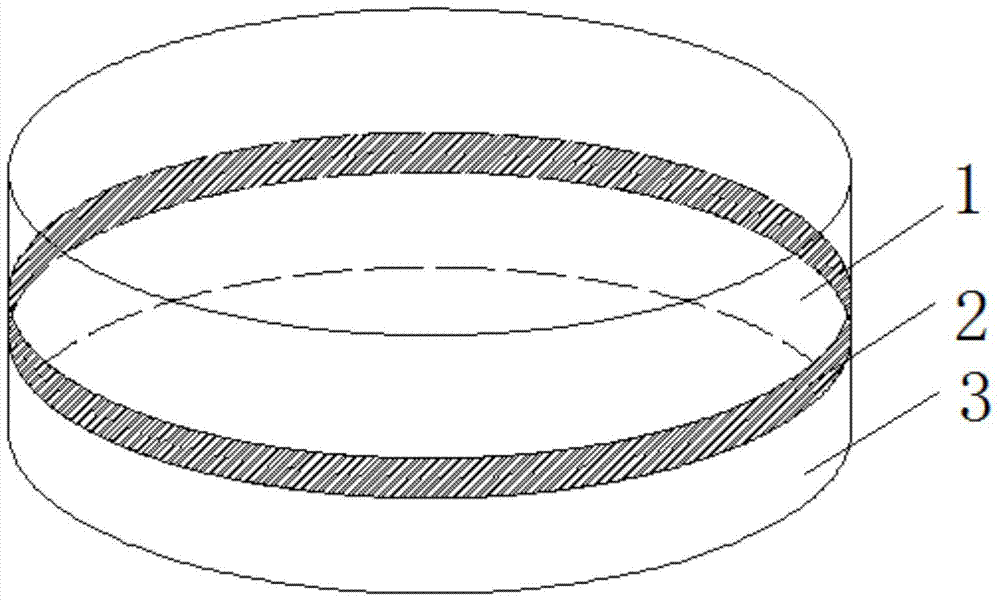

[0032] Such as figure 1 As shown, a molybdenum and graphite composite connector with a cylindrical structure was prepared, wherein the size of the composite connector was 15 mm in diameter and 15 mm in height. Select graphite block and pure molybdenum; perform surface pretreatment on the surface of graphite block 1 and molybdenum sheet 3: use 280, 320 and 400 gauze paper to polish the surface of graphite block 1 and molybdenum sheet 3 in order to remove surface impurities and burrs Finally, clean it with absolute ethanol, and then dry it separately in a blast drying oven at a temperature of 70°C; prepare Ti / Zr solder sheet 2, put Ti powder and Zr powder in a ball mill with a mass ratio of 1:1 and mix for 4 hours , to obtain the mixed powder, then spread the mixed powder in a steel pressing mold, press and form it in one direction on a hydraulic press, press 300MPa, hold the pressure for 1min, and then demould, the thickness of the Ti / Zr brazing filler metal sheet 2 is 1mm; La...

Embodiment 2

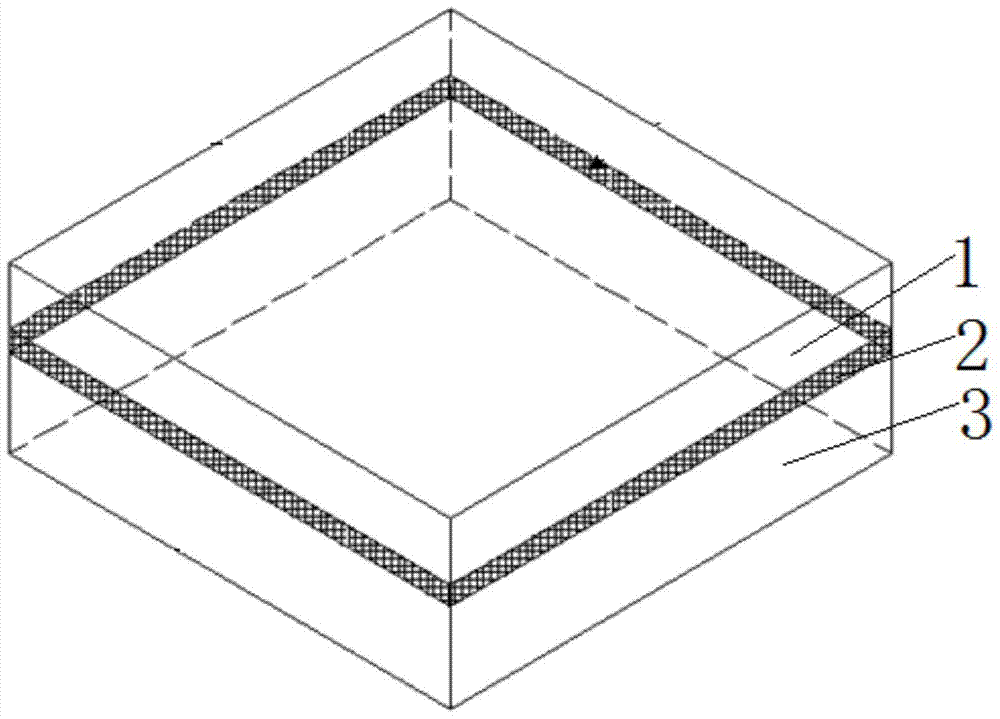

[0034] Such as figure 2 As shown, a molybdenum and graphite composite connector with a laminated structure was prepared, wherein the length, width, and height of the composite connector were 15×15×15 mm, respectively. Select graphite block and molybdenum-boron alloy; carry out surface pretreatment on the surface of graphite block 1 and molybdenum sheet 3: use 280, 320 and 400 gauze papers to polish the surfaces of graphite block 1 and molybdenum sheet 3 in turn to remove surface impurities and After the burr, clean it with absolute ethanol, and then dry it separately in a blast drying oven with a temperature of 75°C; prepare Ti / Zr solder sheet 2, put Ti powder and Zr powder in a ball mill at a mass ratio of 1:1 and mix them 5h, the mixed powder was obtained, and then the mixed powder was flatly spread in a steel pressing mold, and unidirectionally pressed and formed on a hydraulic press, the pressure was 330MPa, the pressure was maintained for 1min, and then demolded, and the...

Embodiment 3

[0036] A cylindrical molybdenum and graphite composite connector was prepared, wherein the size of the composite connector was 10 mm in diameter and 13 mm in height. Select graphite block and tungsten-molybdenum alloy; carry out surface pretreatment on the surface of graphite block 1 and molybdenum sheet 3: use 280, 320 and 400 gauze paper to polish the surfaces of graphite block 1 and molybdenum sheet 3 in turn to remove surface impurities and After the burr, clean it with absolute ethanol, and then dry it separately in a blast drying oven with a temperature of 80°C; prepare Ti / Zr solder sheet 2, put Ti powder and Zr powder in a ball mill at a mass ratio of 1:1 and mix them 5h, the mixed powder was obtained, and then the mixed powder was flatly spread in a steel pressing mold, and unidirectionally pressed and formed on a hydraulic press, the pressure was 350MPa, the pressure was maintained for 1min, and then demolded, and the thickness of the Ti / Zr brazing filler metal sheet 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com