Cotton processing production line

A production line, cotton technology, applied in the direction of continuous processing, separation of plant fibers from seeds, textiles and papermaking, etc., can solve the problems of inconvenient operation, low efficiency, and the quality of cotton processing cannot be guaranteed, and improve processing quality and efficiency. The effect of high and improving planting enthusiasm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

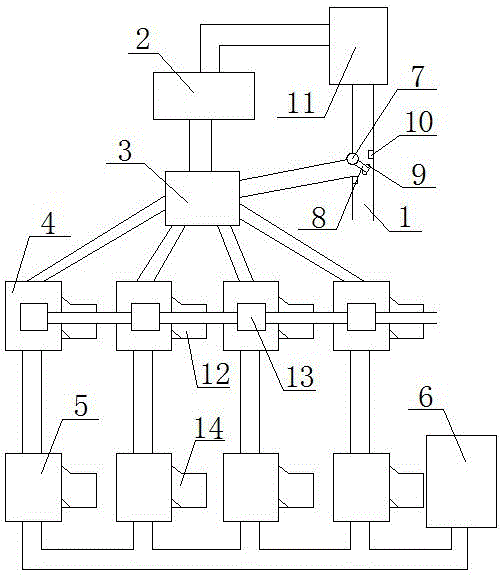

[0016] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises feed port 1, and feed port 1 is connected with dryer 2 and seed cotton cleaning machine 3 respectively, and dryer 2 is connected with seed cotton cleaning machine 3, and seed cotton cleaning machine 3 is connected with several cotton gins 4, and cotton gin 4 They are respectively connected with the skin cleaning machine 5, and the skin cleaning machine 5 is connected with the baler 6 respectively. The feed port 1 is provided with a baffle plate 8 that can rotate around the rotating shaft 7, the end of the baffle plate 8 is provided with a latch 9, and both sides of the feed port 1 are respectively provided with insertion noses 10 used in conjunction with the latch 9. A separator 11 is installed between the feed port 1 and the dryer 2 . Cottonseed recoverers 12 are respectively provided at the bottom of the cotton gin 4 . Vacuum cleaners 13 are respectively install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com