Base plate of four-crawler-belt sliding formwork paver

A slip-form paver and four-track technology, which is applied to roads, road repairs, roads, etc., can solve problems such as incompetence, narrow use range, and difficult construction, and achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

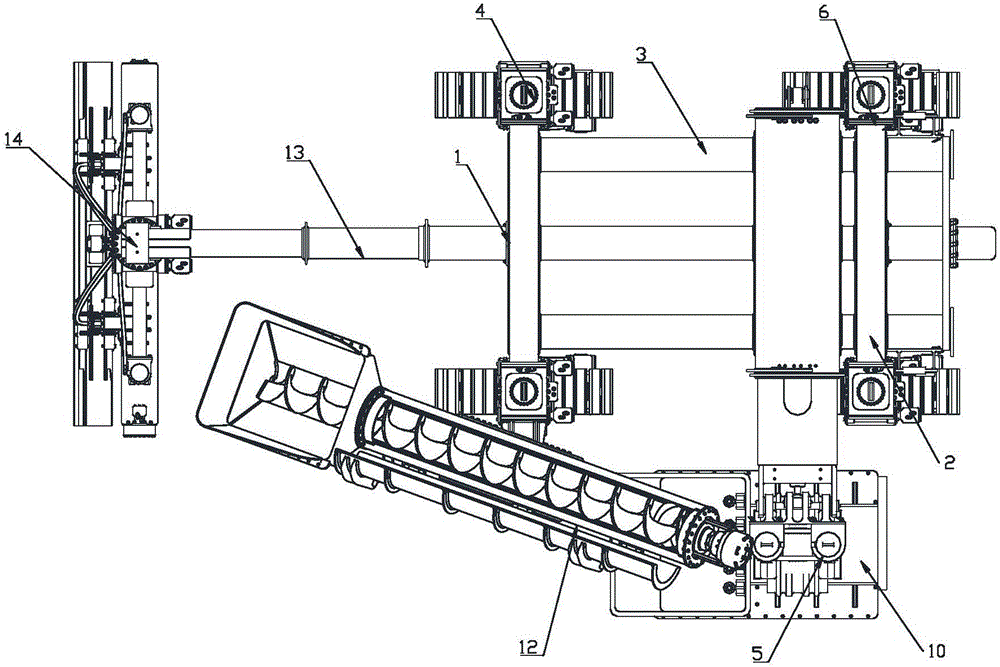

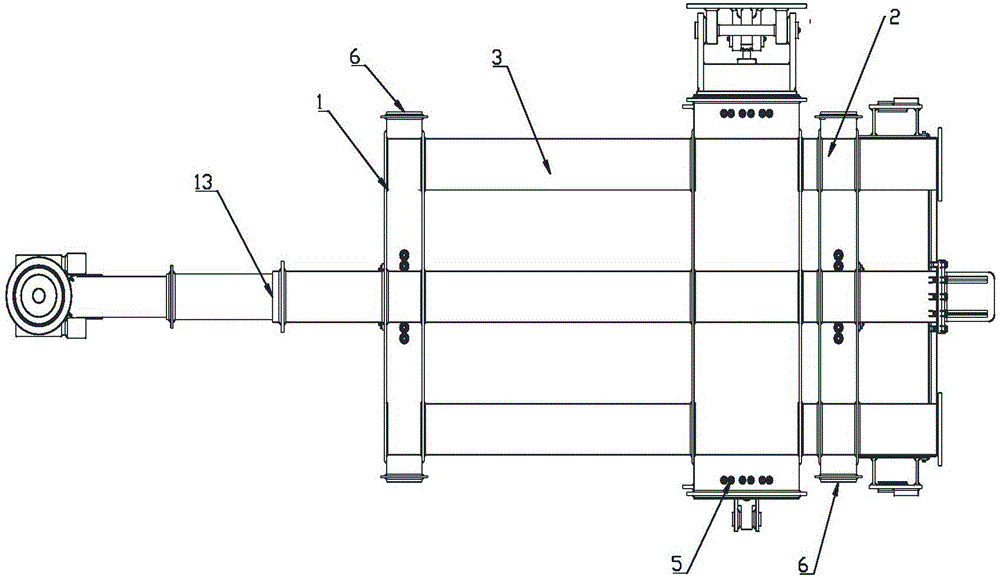

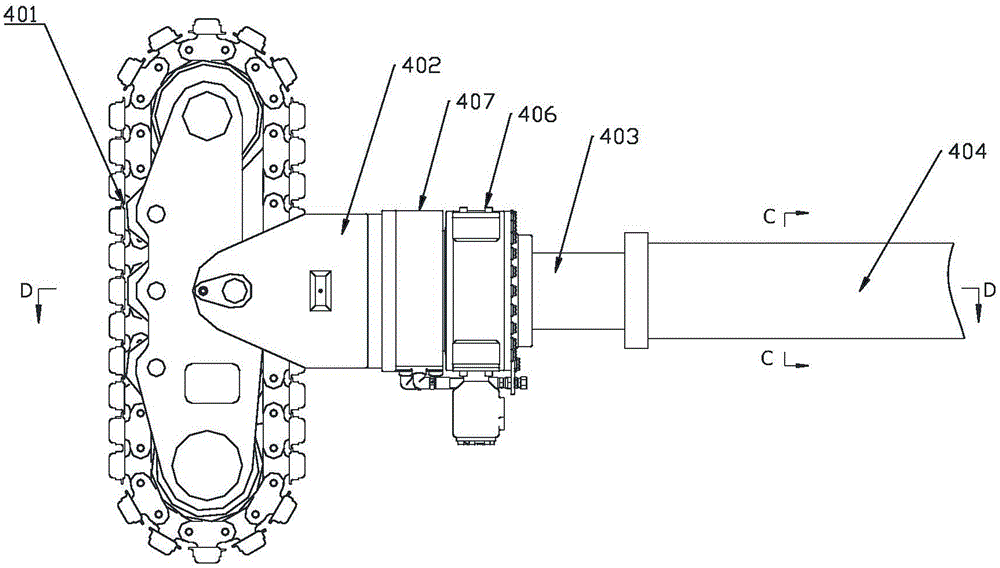

[0035] Such as Figure 1 to Figure 11 As shown in the figure, the chassis of a four-track slipform paver includes a hollow horizontal front beam 1 and a hollow horizontal rear beam 2 arranged side by side in the same horizontal plane. The two ends of the horizontal front beam 1 and the horizontal rear beam 2 respectively pass through the longitudinal beams 3 The two ends of the transverse front beam 1 and the transverse rear beam 2 are respectively connected to the traveling steering device 4, and a leveling head telescopic beam 13 arranged parallel to the longitudinal beam is provided between the two longitudinal beams 3, and the leveling head telescopic beam 13 penetrates Passing the bottom center position of the transverse front beam 1 and the transverse rear beam 2 and perpendicular to the transverse front beam 1 and the transverse rear beam 2, the leveling head telescopic beam 13 is provided with a leveling head 14 at one end close to the transverse front beam 1.

[0036] The...

Embodiment 2

[0041] Such as Figure 3 to Figure 6 and Figure 8 to Figure 15 As shown in the figure, the overall structure of this embodiment 2 is the same as that of embodiment 1, except that the longitudinal beam 3 on the rear side of the transverse rear beam 2 is provided with a mold connection port 7, and the mold connection port 7 is connected to the rear mold 8.

[0042] The rear mold 8 includes a beam frame 801, a rectangular connecting beam 802, a spiral cloth shaft 803, a vibrating rod 804, a wiper plate 805, and a side adjustment plate 806. The beam frame 801 includes a square main beam frame 807, which is fixed above the main beam frame 807 A rectangular connecting beam 802 is provided. The front and rear faces of the rectangular connecting beam 802 are welded with connecting ports 808. The connecting ports 808 are used to connect with the mold connecting port 7. A spiral cloth shaft 803 is fixed at the bottom of the front end of the main beam frame 802. The vibrating rod cylinder 8...

Embodiment 3

[0044] Such as Figure 3 to Figure 11 and Figure 16 to Figure 18 As shown in the figure, the chassis of a four-track slipform paver includes a hollow horizontal front beam 1 and a hollow horizontal rear beam 2 arranged side by side in the same horizontal plane. The two ends of the horizontal front beam 1 and the horizontal rear beam 2 respectively pass through the longitudinal beams 3 The two ends of the transverse front beam 1 and the transverse rear beam 2 are respectively connected to the traveling steering device 4, and a leveling head telescopic beam 13 arranged parallel to the longitudinal beam is provided between the two longitudinal beams 3, and the leveling head telescopic beam 13 penetrates Passing the bottom center position of the transverse front beam 1 and the transverse rear beam 2 and perpendicular to the transverse front beam 1 and the transverse rear beam 2, the leveling head telescopic beam 13 is provided with a leveling head 14 at one end close to the transver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com