Clean water and sewage separate two-stage drainage system of bridge

A drainage system and sewage cleaning technology, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problems of bridge load increase and the impact of bridge deck sewage on the surrounding environment, etc., and achieve the effect of strong adaptability and high promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

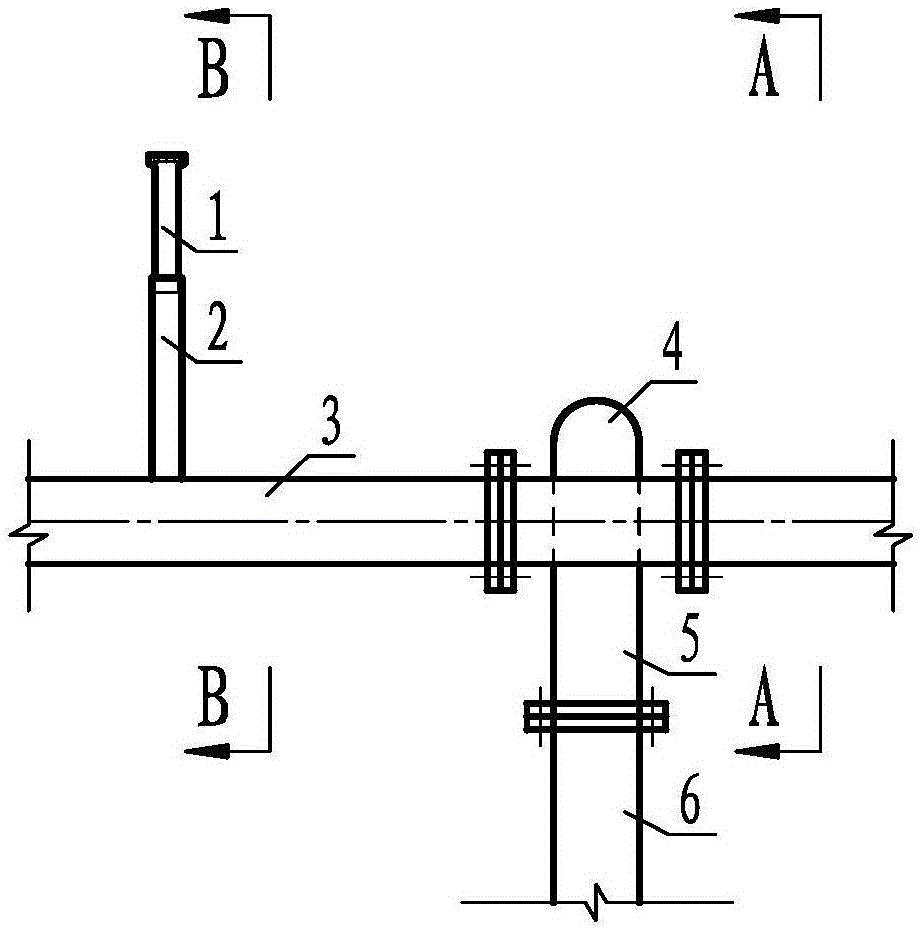

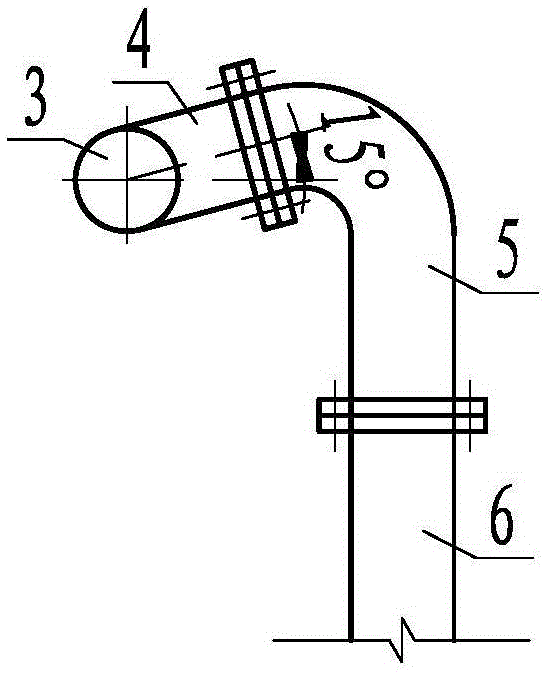

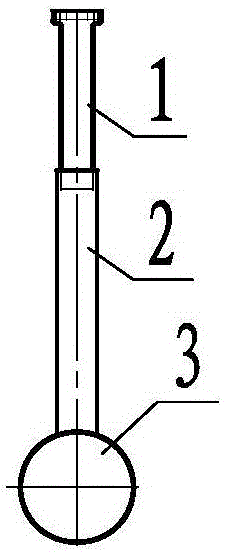

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] refer to figure 1 , 2 , 3, the diameter of the upper discharge pipe 1 of the present invention is less than the diameter of the lower discharge pipe 2, and the socket joints of the upper and lower discharge pipes are filled with linoleum. The drain pipe is communicated with the longitudinal drain pipe 3 . The longitudinal drainage pipe 3 is provided with a longitudinal slope, and the bottom of the longitudinal slope is connected with the sewage treatment system. The vertical drainage pipe is provided with a tee 4 with an oblique upward water outlet, and the bottom of the tee outlet is higher than the bottom of the longitudinal drainage pipe at the corresponding position, and the height difference is the water level limit value. The end of the three-way water outlet is connected to the vertical drain pipe 6 through the flexible pipe 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com