aluminum housing

A technology of aluminum alloy and aluminum alloy beams, applied in the direction of roofs, building components, floors, etc., can solve the problem of not adopting thermal insulation, sound insulation, waterproofing, fire prevention, walls that cannot be dismantled or displaced, and restricted space layout freedom, etc. problems, to achieve the effect of superior seismic performance, outstanding advantages in assembly operations, and reduced temporary land use for operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

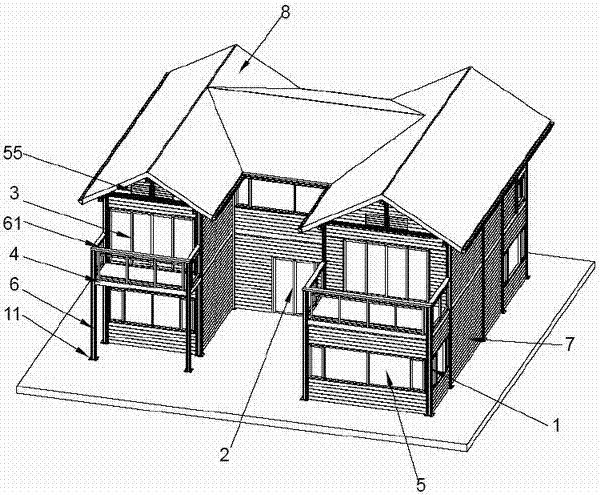

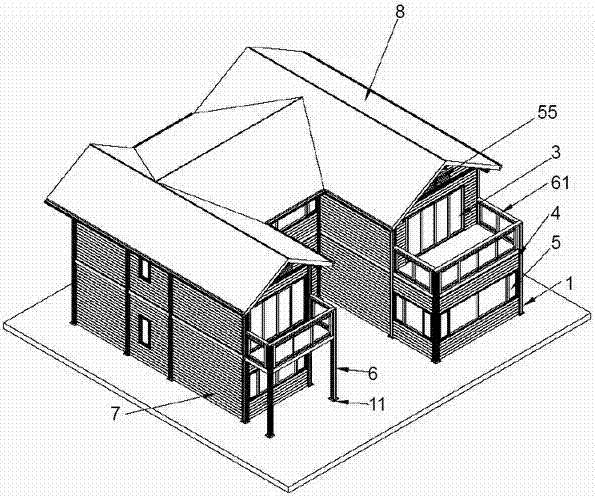

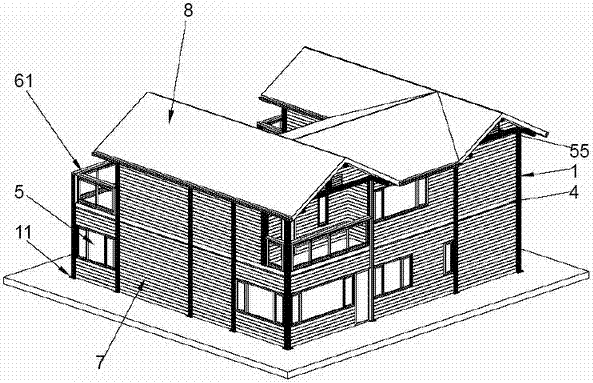

[0058] see Figure 1 to Figure 8 , the present invention provides an aluminum alloy house, which mainly consists of an aluminum alloy column 1, a column support 11, an aluminum alloy gate 2, an aluminum alloy door 3, an aluminum alloy beam 4, an aluminum alloy window 5, an aluminum alloy shutter 55, an aluminum alloy The balcony column 6, the aluminum alloy balcony railing 61, the aluminum alloy composite wall panel 7, the roof support column 10, the roof 8, and the bottom and second floor slabs 9.

[0059] The aluminum alloy columns 1 are arranged at intervals on the periphery and the inner ring of the house, and the aluminum alloy beams 4 are vertically and horizontally connected to the middle position of the outer aluminum alloy column 1 and the height of the inner ring aluminum alloy column 1, forming the ground floor and the second floor of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com