Improved hydraulic oil tank

A hydraulic oil tank and improved technology, applied in the direction of oil supply tank device, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve the problem of inconvenient disassembly and cleaning, limited ability to filter iron particles, and inability to further ensure hydraulic oil. High quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

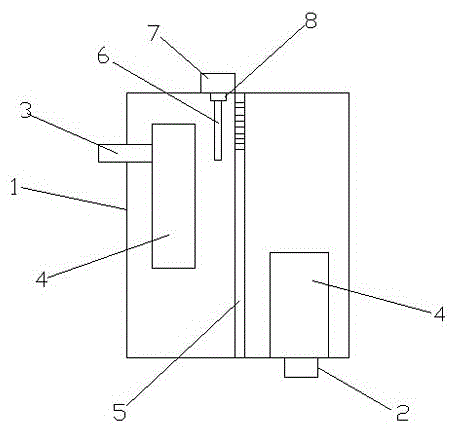

[0016] figure 1 It is a structural schematic diagram of an improved hydraulic oil tank according to the embodiment of the present invention; the hydraulic oil tank includes a tank body 1, an oil suction pipe 2, an oil return pipe 3, a filter assembly 4 and a partition 5, and the filter assembly 4 is installed on the oil suction pipe 2 and the oil return pipe. At the end of the oil pipe 3, the partition plate 5 is vertically installed in the middle of the casing 1, and an electromagnet adsorption device is added on the casing 1. The device mainly consists of a magnetic bar 6, a housing 7, a battery, Switches, control elements and related circuits,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com