Mine hydraulic cylinder capable of achieving hydraulic medium replacement under pressure

A technology of hydraulic medium and hydraulic cylinder, applied in the hydraulic field, can solve the problems of increasing manufacturing cost, increasing corrosion, complicated process, etc., and achieving the effect of low cost and delaying corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to clearly illustrate the technical features of the solution of the present invention, the present invention will be described below in conjunction with specific embodiments and accompanying drawings.

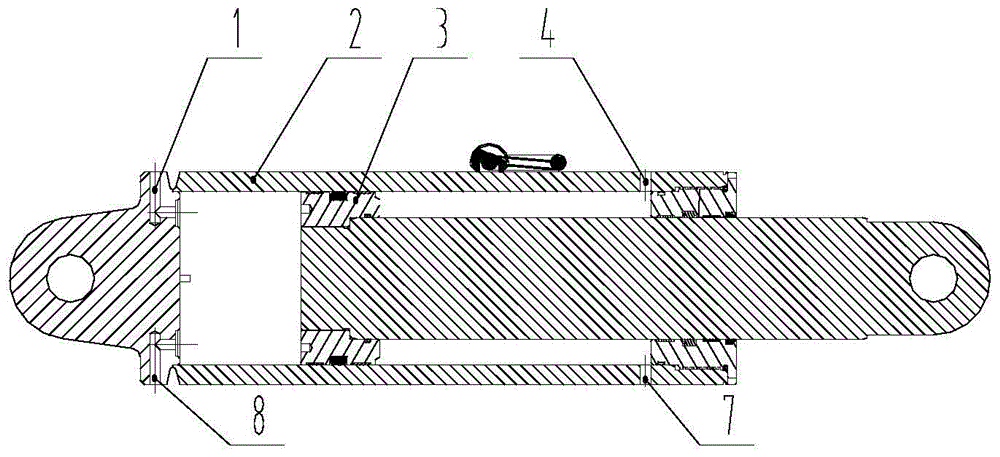

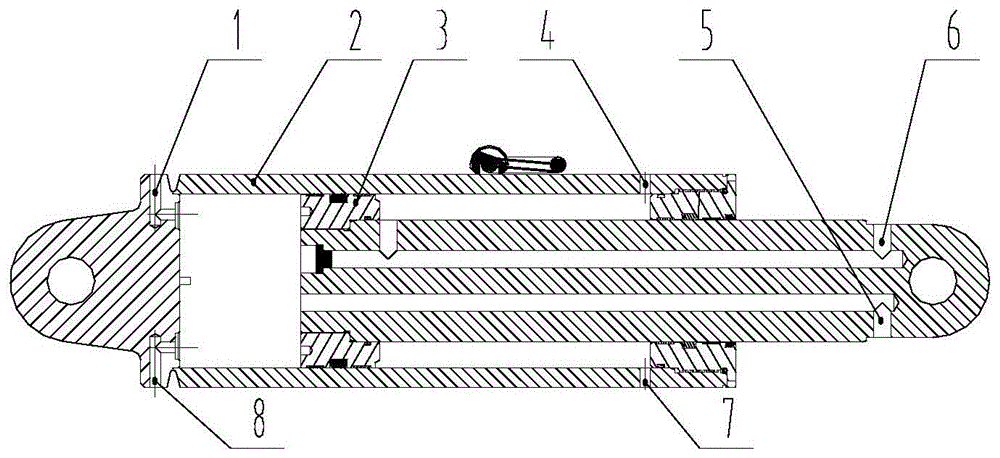

[0022] Such as figure 1 As shown, the hydraulic cylinder of the prior art includes a cylinder body 2, a piston 3 located in the cylinder body 2, and a piston rod that is integrated with the piston 3 and extends out of the cylinder body 2, and the space in the cylinder body 2 is divided by the piston 3. Rod cavity part and rod cavity part. The rodless cavity safety valve interface 1 and the rodless cavity control liquid interface 8 are provided in the rodless cavity part, the safety valve (not shown in the figure) is connected with the rodless cavity part through the rodless cavity safety valve interface 1, and the liquid supply pipe The road is connected to the rodless chamber part through the rodless chamber control fluid interface; similarly, the rod chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com