Rust-proof cap nut

A nut and cap technology, applied in the direction of nuts, bolts, threaded fasteners, etc., can solve problems such as affecting the appearance, corrosion, waste of cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

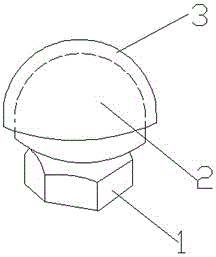

[0010] Attached icon number: 1. Nut body, 2. Cap, 3. Sealing rubber.

[0011] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] The structure of the present invention is as figure 1 As shown, a rust-proof cap nut is characterized in that it comprises a nut body 1 and a cap 2 integrally formed with the nut body 1. The nut body 1 is in the shape of a hexagonal prism, and the diameter ratio of the cap 2 to the nut body 1 is 2:1, the cap 2 is larger than the nut, and the arc on the top of the cap 2 can throw off the rain, thereby effectively preventing the outside air and moisture from entering; the nut body 1 is nickel-plated, and the nut can quickly on the surface A very thin passivation film is formed, which is highly stable in the air; a sealing rubber 3 is sleeved on the cap 2, which can res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com