Bladder type molecular spring vibration isolation buffer

A molecular spring and buffer technology, used in springs/shock absorbers, springs, shock absorbers, etc., can solve the problems of insufficient bearing capacity, easy aging, large static deformation of vibration isolators, etc., to achieve strong bearing capacity, high Bearing capacity, effect of low natural frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings:

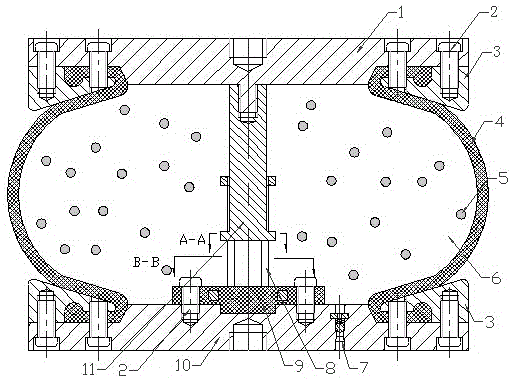

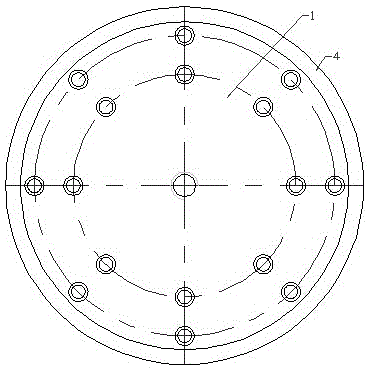

[0028] Such as figure 1 As shown, the capsule type molecular spring vibration isolation buffer, the capsule body 4 is arranged between the upper end plate 1 and the lower end plate 10, and the capsule type container is formed by the fastening screw 2 and the fastening flange 3 to lock and seal; the molecular spring mixed medium Placed in a capsule container, the capsule body 4 is filled with a molecular spring mixed medium; the capsule body 4 changes according to the change of the distance between the upper end plate 1 and the lower end plate 10.

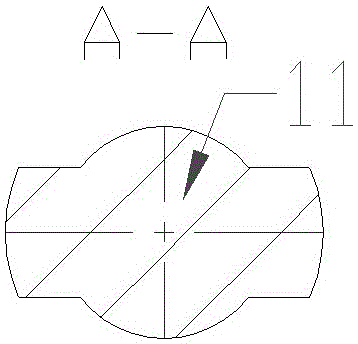

[0029] Such as image 3 As shown: the upper end plate 1 is connected with the lower guide shaft 11 through threads. The end of the guide shaft 11 has two radial protrusions; the guide shaft 11 is arranged in the limit sleeve 8, and the lower part of the limit sleeve 8 is a disc structure. The buffer rubber 9 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com