Coal and tobacco stem co-fired boiler and its pollutant control method

A tobacco stem and co-firing technology, applied in the combustion method, combustion type, combustion equipment and other directions, can solve the problems of coking, ash accumulation, coal and tobacco stem slagging, etc., and achieve the effects of reducing wear, solving coking and low speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

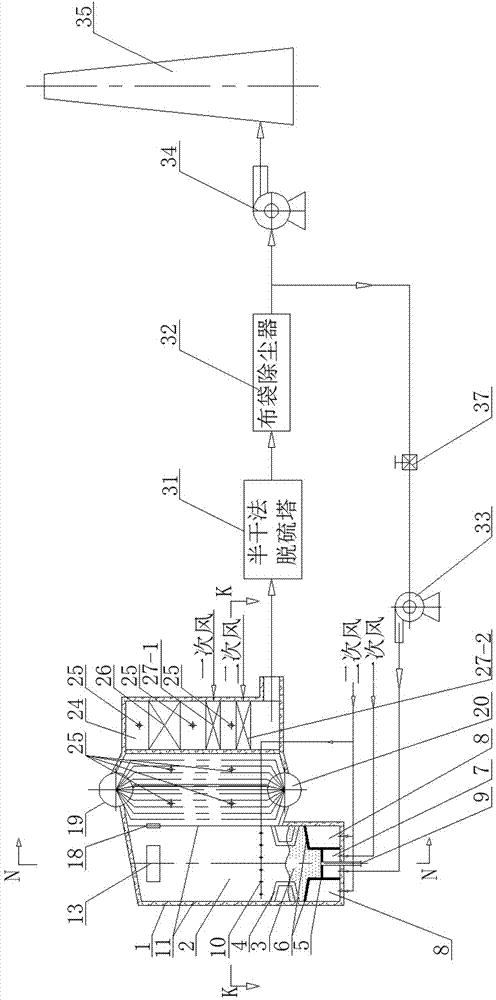

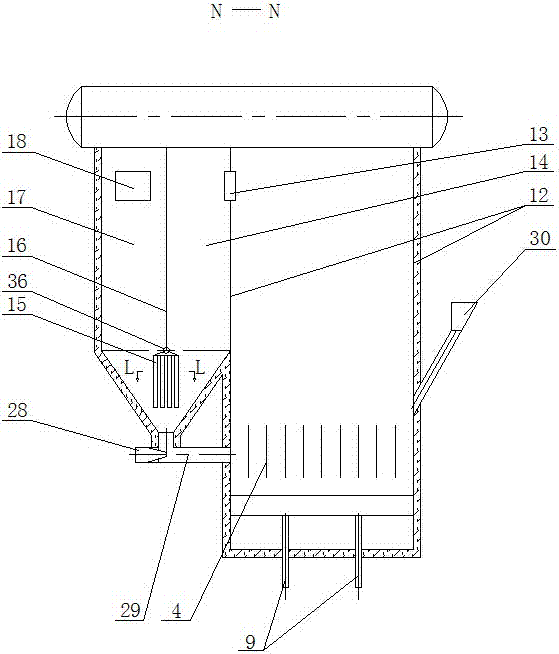

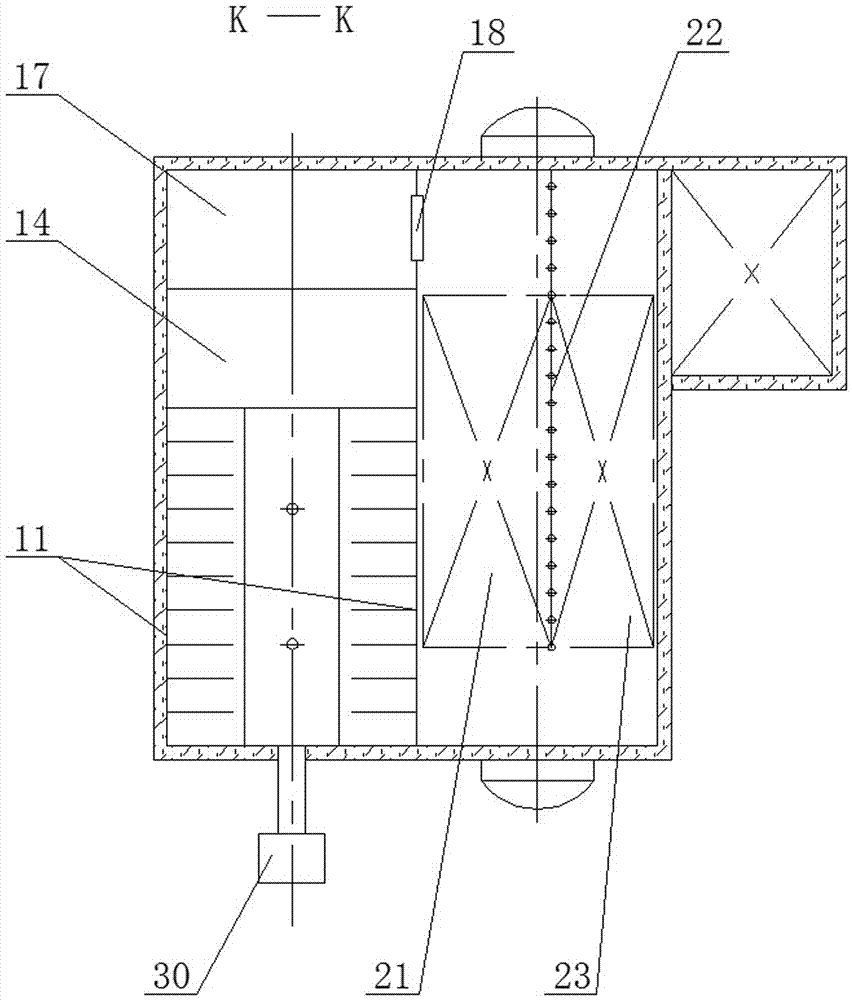

[0036] Specific implementation mode one: as Figure 1~Figure 4 As shown, the coal and tobacco stem co-fired boiler includes a fluidized bed combustion chamber 1, a fluidized bed dilute phase area 2, a fluidized bed dense phase area 3, multiple buried pipes 4, a high-speed bed air distribution plate 5, two Low-speed bed distribution air plate 6, high-speed bed air chamber 7, low-speed bed air chamber 8, slag outlet 9, multiple secondary air outlets 10, left and right wall membrane water cooling walls 11, front and rear wall membrane water cooling walls 12, combustion chamber outlet 13. The first cooling chamber 14, the U-shaped groove separator 15, the intermediate membrane water wall partition wall 16, the second cooling chamber 17, the flue gas outlet 18, the upper steam drum 19, the lower steam drum 20, and the first convection pipe 21 , Convection pipe partition wall (membrane wall) 22, second convection pipe 23, tail flue gas channel 24, multiple pulse soot blowers 25, eco...

specific Embodiment approach 2

[0038] Specific implementation mode two: as figure 1 As shown, in the coal and tobacco stem co-firing boiler described in Embodiment 1, an adjustment baffle 37 is provided on the flue connected to the inlet end of the recirculation fan 33 and the outlet end of the bag filter 32 for adjusting Circulating flue gas volume.

specific Embodiment approach 3

[0039] Specific implementation mode three: as Figure 1~Figure 4 As shown, the method for realizing pollutant control by using coal and tobacco stem co-fired boiler described in the specific embodiment one or two, the method includes the following steps:

[0040] Step 1: Coal, tobacco stems and kaolin (additive) with a diameter of ≤ 2mm enter the high-speed bed in the dense phase zone 3 of the fluidized bed through the feed port 30 and burn by gravity (because it is a negative pressure feed, the feed port 30 It is a slight negative pressure and will not spray fire outwards. When the negative pressure at the outlet 13 of the combustion chamber is about -150Pa, negative pressure feeding can be realized), and the heat generated by combustion passes through the low-speed bed arranged in the fluidized bed combustion chamber 1 Control the temperature of the high-speed bed and low-speed bed in the dense-phase area 3 of the fluidized bed between 800 and 850°C after heat exchange with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com