Energy conversion system based on metal microporous pipe network

A technology of energy conversion system and microporous tube, which is applied in the field of energy conversion system, can solve the problems of high production cost, failure to achieve expected index of energy conversion efficiency, low cost performance, etc., achieve low cost, solve the problem of pipe network antifreeze, and ensure qualified rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

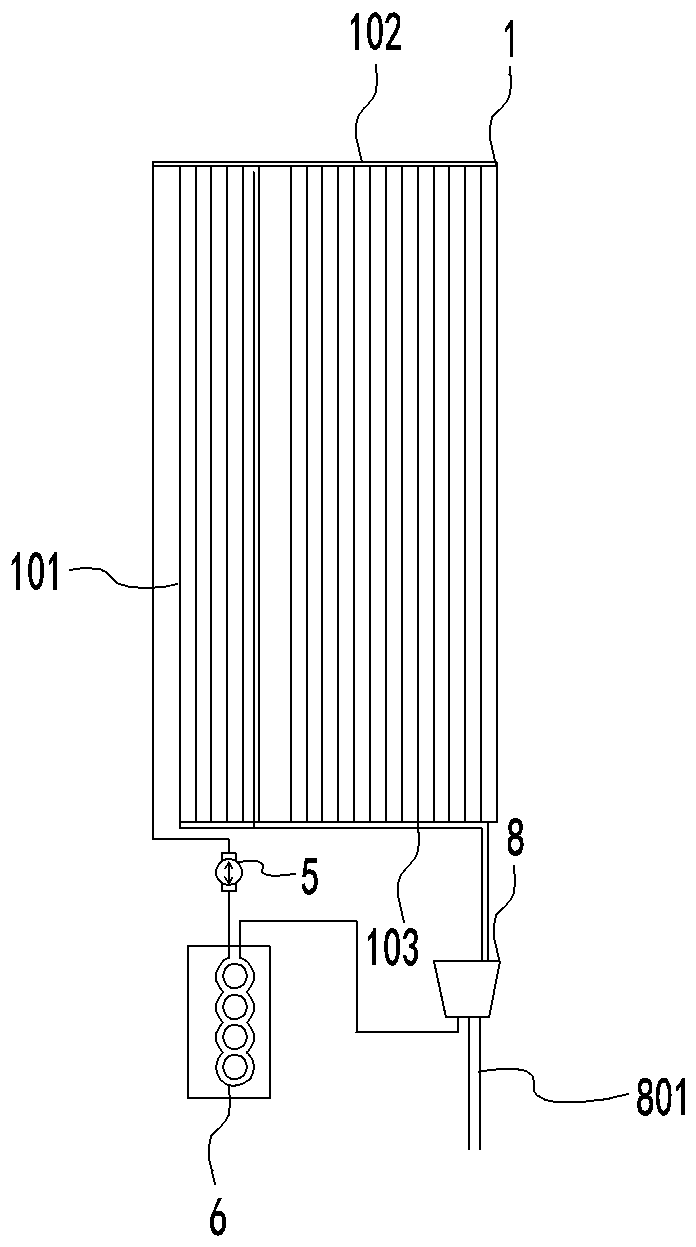

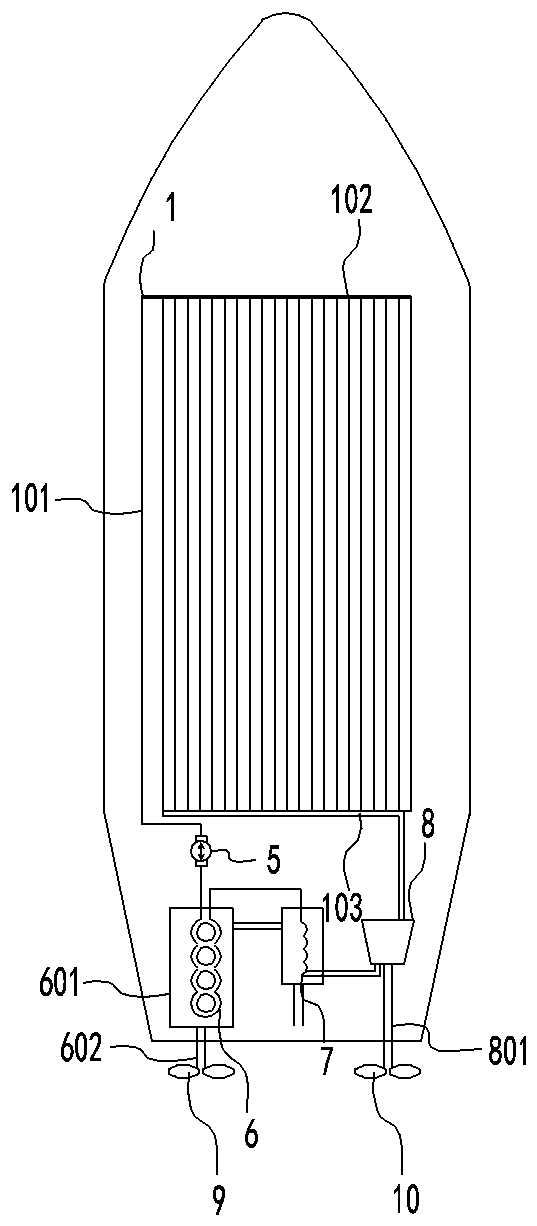

[0036] Waste heat compound power ship application system.

[0037] See figure 2 As shown, the energy conversion system based on metal microporous pipe network (waste heat composite power ship application system) includes refrigerant heat exchange component 1, hydraulic pump 5, heat exchanger 6, smoke exhaust pipe heat exchanger 7 and power turbine 8 A pipeline port of the liquid distributor 102 of the refrigerant heat exchange assembly 1 is connected to the heat exchange input port of the heat exchanger 6 via the hydraulic pump 5; the heat exchange output port of the heat exchanger 6 is connected to the power turbine The inlet of the engine 8 is connected; the outlet of the power turbine 8 is connected to the gas distributor 103 of the refrigerant heat exchange assembly 1; the heat exchange output port of the heat exchanger 6 is connected to the heat exchanger 7 through the exhaust pipe The inlet of the power turbine 8 is connected; the power turbine 8 transmits power to the out...

Embodiment 2

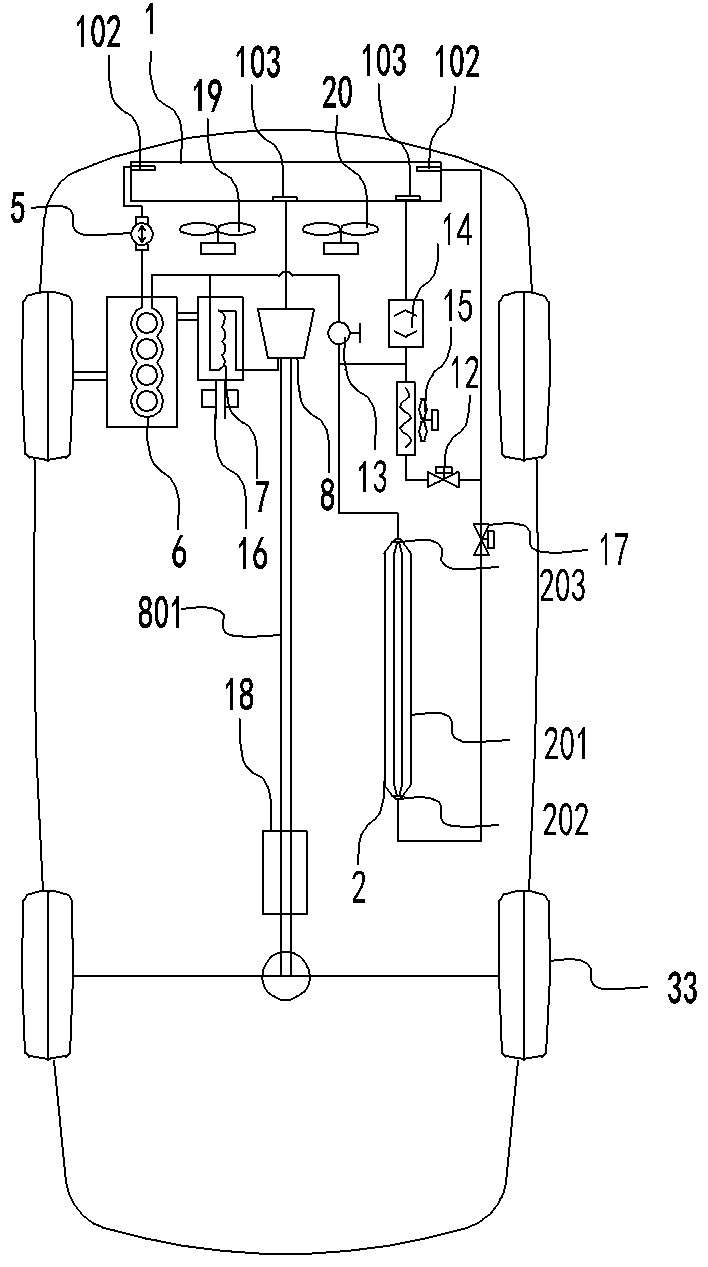

[0043] Air-cooled heat exchanger waste heat dual-power automobile application system.

[0044] See image 3 As shown, the energy conversion system based on metal microporous pipe network (air-cooled heat exchanger waste heat dual-power automobile application system) includes refrigerant heat exchange component 1, hydraulic pump 5, heat exchanger 6, exhaust pipe heat exchanger 7 and Power turbine 8; a pipeline port of the liquid distributor 102 of the refrigerant heat exchange assembly 1 is connected to the heat exchange input port of the heat exchanger 6 via the hydraulic pump 5; the heat exchange output of the heat exchanger 6 The port is connected with the inlet of the power turbine 8; the outlet of the power turbine 8 is connected with the gas distributor 103 of the refrigerant heat exchange assembly 1; the heat exchange output port of the heat exchanger 6 is connected through the exhaust pipe The heat exchanger 7 is connected to the inlet of the power turbine 8; the power tur...

Embodiment 3

[0061] Refrigerant heat transfer component aircraft waste heat power application system.

[0062] See Figure 4 As shown, the energy conversion system based on metal microporous pipe network (refrigerant heat transfer component aircraft waste heat power application system), including refrigerant heat exchange component 1, hydraulic pump 5, heat exchanger 6, smoke exhaust pipe heat exchanger 7 and power Turbine 8; a pipeline port of the liquid distributor 102 of the refrigerant heat exchange assembly 1 is connected to the heat exchange input port of the heat exchanger 6 via the hydraulic pump 5; the heat exchange output port of the heat exchanger 6 Connected with the inlet of the power turbine 8; the outlet of the power turbine 8 is connected with the gas distributor 103 of the refrigerant heat exchange assembly 1; the heat exchange output port of the heat exchanger 6 is exchanged through the exhaust pipe The heat exchanger 7 is connected to the inlet of the power turbine 8; the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com