Two-stroke elasticity internal combustion engine

An internal combustion engine and two-stroke technology, applied in the direction of internal combustion piston engines, combustion engines, engine components, etc., can solve the problems of less power stroke, large energy consumption, and large impact force, and achieve strong power, fuel saving, and increased power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

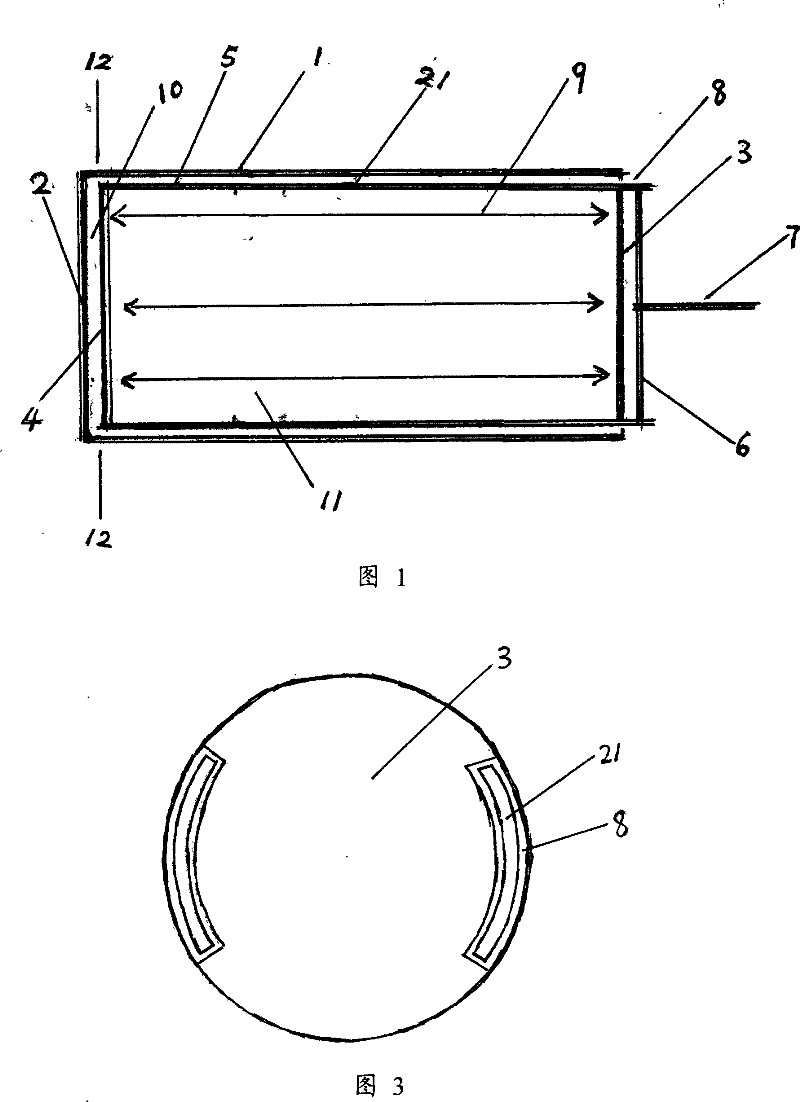

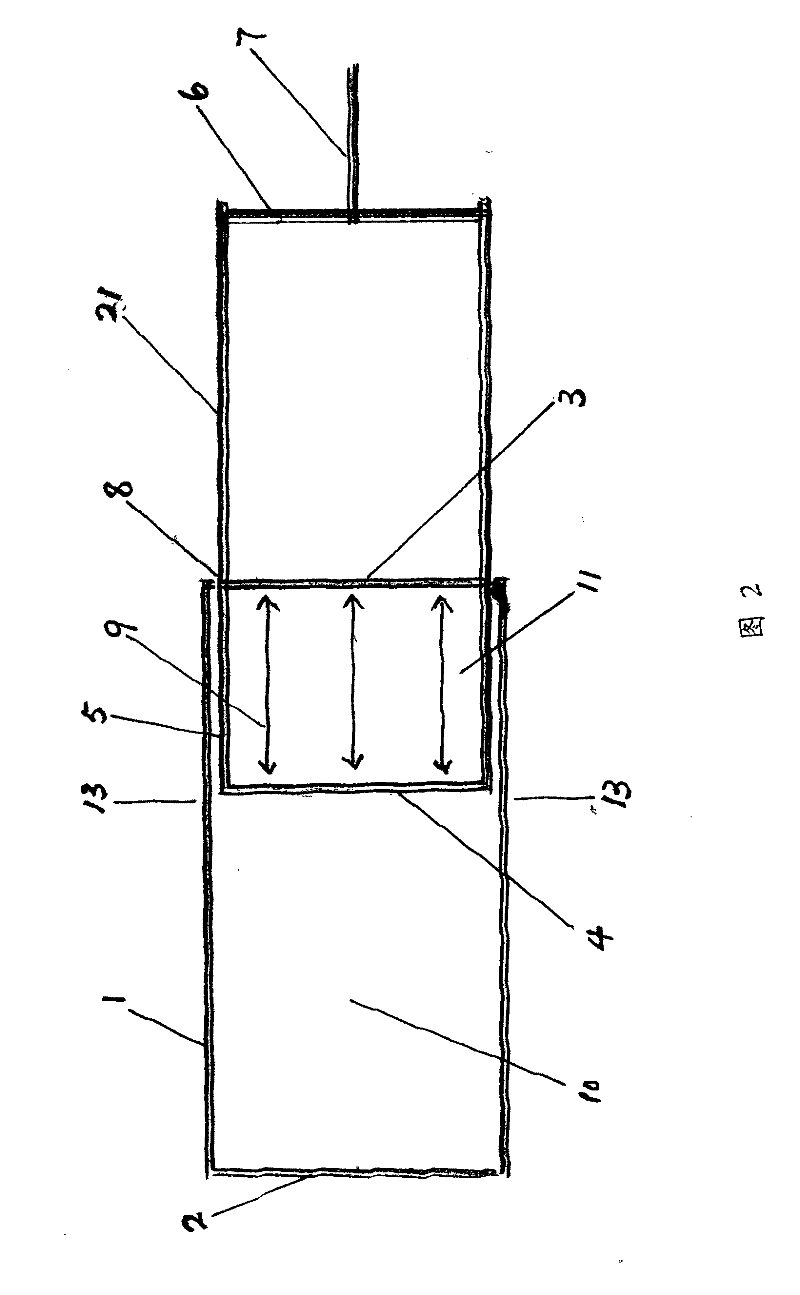

[0034] Embodiment 1, with reference to Figure 1 ~ Figure 3 Cylinder 1 of novel elastic internal combustion engine is provided with top cover 2 and bottom cover 3, and the corresponding parts of the front and back sides of piston 4 and cylinder inner surface respectively constitute volume-variable combustion studio 10 and elastic studio 11. Elasticity working room is built-in with the elastic accumulator body 9 of storing certain pressure. The elastic energy storage body 9 of the present embodiment is compressed air. The bottom of the piston 4 body is a piston skirt 5 (between them is a piston head, an annular groove is provided, and a piston ring is placed in the annular groove), and the extension of the piston skirt 5 is an arc-shaped plate body 21 that is symmetrically spaced; at the same time, A symmetrical arc-shaped hole 8 is opened on the cylinder bottom cover 3, and the shape and size of the hole 8 and the piston skirt extension 21 are consistent, and a dynamic sealin...

Embodiment 2

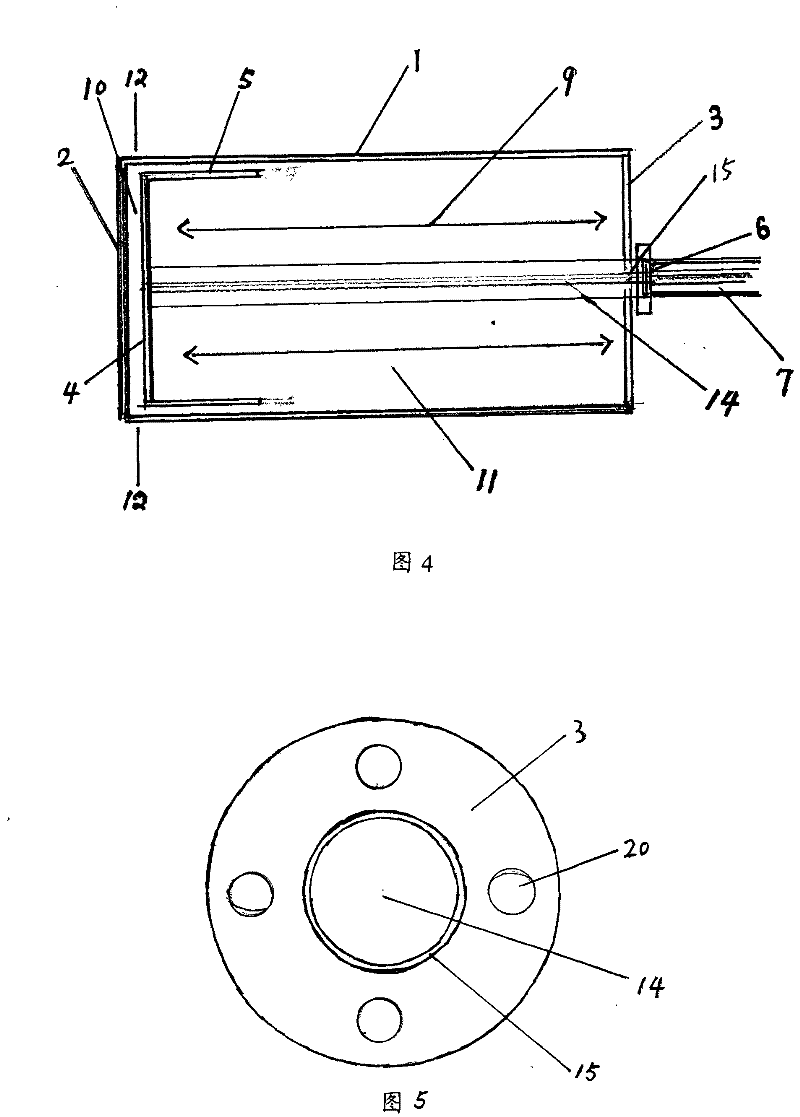

[0044] Embodiment 2, with reference to Figure 4 , Figure 5 : Basically the same as Example 1, but with the following changes:

[0045] Use the piston rod 14 to carry out dynamic sealing connection with the central circular hole 15 on the cylinder bottom cover;

[0046] The elastic energy storage body 9 is liquid and compressed air (a film can be interposed between the two), the liquid is on the top, and the compressed air is on the bottom; the liquid accounts for about 1 / 8 to 1 / 3 of the entire cylinder space, and the compressed gas accounts for about 7 / 8 to about 2 / 3; under the pressure of the expansion force, with the displacement of the piston, the compressed gas can shrink into the energy storage adjustment mechanism, the expansion force disappears, and the compressed gas is pressed back into the elastic chamber.

Embodiment 3

[0047] Embodiment 3, with reference to Figure 6 , Figure 7 , Figure 8 : Basically the same as Example 1, but with the following changes:

[0048] The piston extension is an arc-shaped slide plate 17 (or other shapes such as a slide bar) symmetrically spaced. is an annular space around the outer diameter of the piston); at the same time, two or more arc-shaped mounting holes 16 on the cylinder bottom cover are also arranged on the outer ring of the cylinder, and the arc-shaped slide plate 17 (or slide rod, etc.) The position, shape and size of other shapes) correspond to each other, and the two form a movable connection. The arc-shaped slide plate can reciprocate in the chute on the cylinder wall. The elastic energy storage body 9 is a composite spring. No energy storage regulating mechanism is provided in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com