A Vibration Detection Method Based on Laser Speckle Defocus Imaging

A vibration detection and defocus imaging technology, applied in the optical field, can solve problems such as difficult functions, inconvenient use, poor performance, etc., and achieve the effects of diverse shapes and materials, strong anti-interference ability, and high information content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the drawings and embodiments.

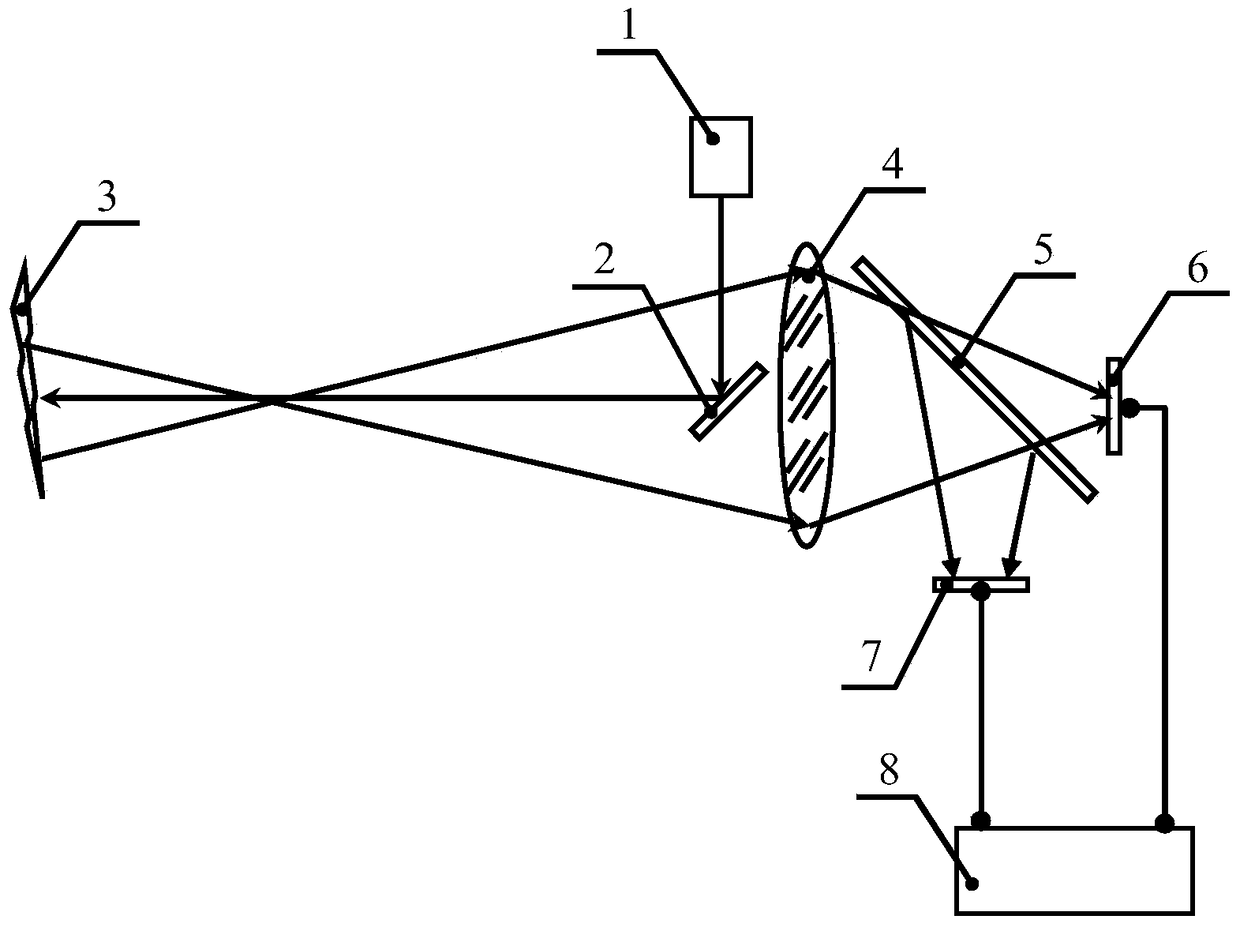

[0026] Such as figure 1 As shown, an embodiment of a vibration detection method based on laser speckle defocus imaging, based on the principle of laser speckle defocus imaging, combined with two-dimensional photoelectric sensor line scanning technology, the laser beam irradiates the detected area, and the laser speckle passes The defocus optical imaging system performs imaging. A beam splitter is arranged in the image space of the defocus optical imaging system to divide the imaging beam into two beams. A two-dimensional photoelectric sensor is installed on the image plane of each imaging beam. The photoelectric sensor works in line scanning. In the imaging mode, the scanning directions of the two photoelectric sensors for line scan imaging are not parallel; the vibration analysis unit performs line scan imaging signal processing to obtain vibration information of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com