Intelligent contactless flame-proof switch

An explosion-proof switch, non-contact technology, used in instruments, computer control, simulators, etc., can solve the problems of inability to realize remote control, telemetry, remote signaling, remote adjustment, low electrical life, and low protection functions, and achieve parameter setting. Simple, easy-to-setup effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

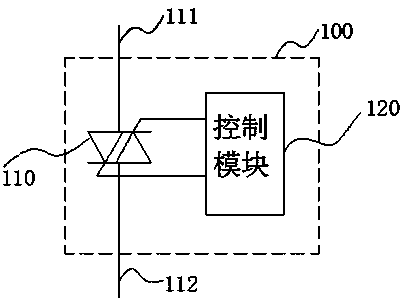

[0034] The invention provides a new type of intelligent non-contact explosion-proof switch, such as figure 1 As shown, the intelligent non-contact explosion-proof switch 100 includes a main control switch (thyristor) 110 and a control module 120 .

[0035] The main control switch (thyristor) 110 has an input terminal 111 for connecting a power supply and an output terminal 112 for connecting a load, and the control module 120 is used to control the main control switch (thyristor) 110 to be turned on and off.

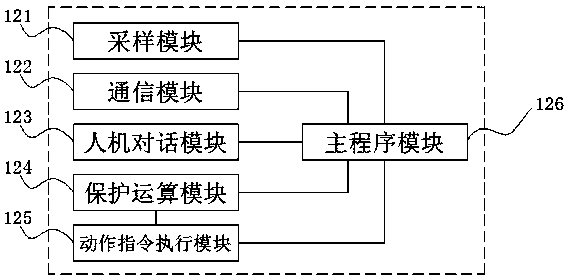

[0036] like figure 2 As shown, the control module 120 includes a sampling module 121 , a communication module 122 , a man-machine dialogue module 123 , a protection calculation module 124 , an action instruction execution module 125 , and a main program module 126 .

[0037] The sampling module 121 collects various parameters in real time and transmits them to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com