Aluminum pipe structure for oil immersed type current transformer

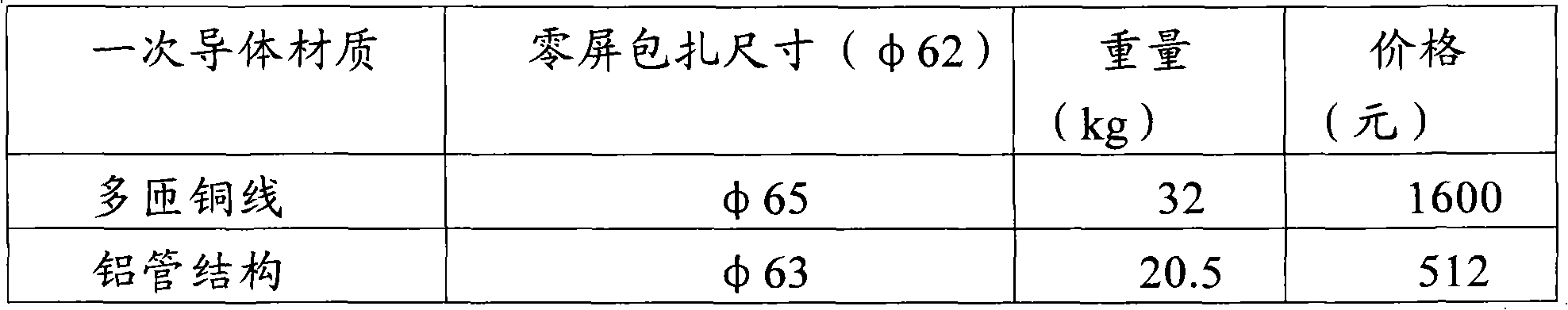

A current transformer, oil-immersed technology, used in inductors, transformers/inductor coils/windings/connections, circuits, etc., can solve the problem of resistance to movement, poor thermal stability, difficult primary winding welding, inter-turn short circuit, etc. problem, to achieve the effect of good thermal stability, considerable economic value, and small size error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

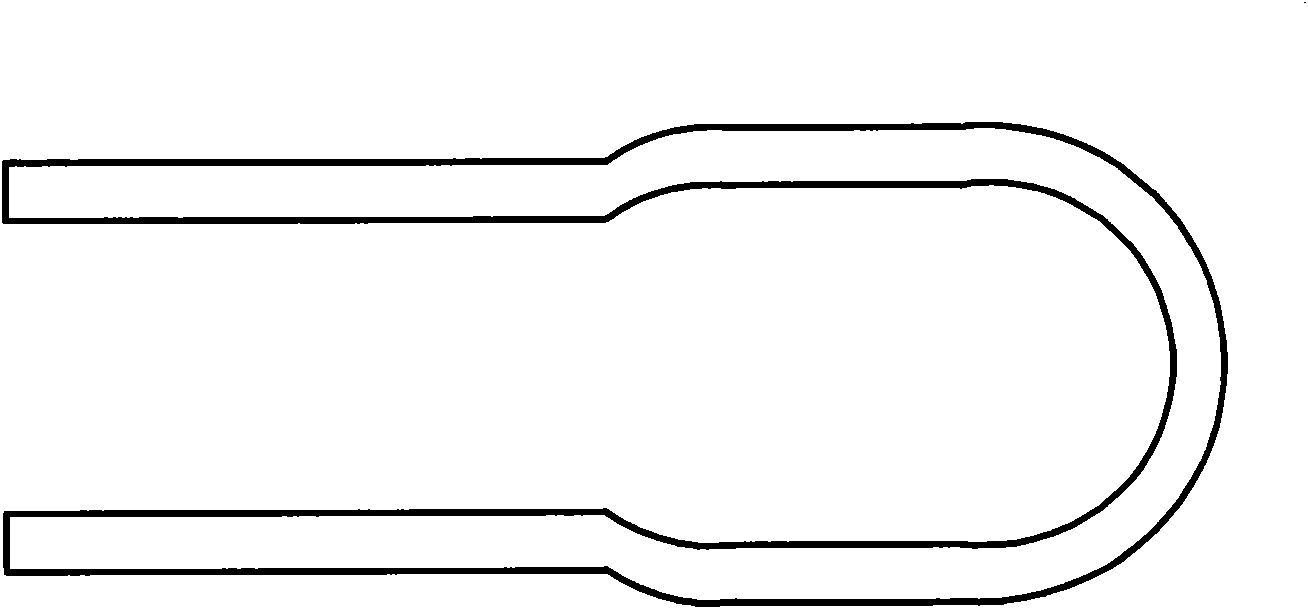

[0009] figure 1 It is a structural schematic diagram of the aluminum tube structure of the present invention; the aluminum tube structure of an oil-immersed current transformer of the present invention is characterized in that: the aluminum tube structure is in a "U" shape, wherein: the " The U"-shaped bottom is wider than the "U"-shaped top; the aluminum tube structure is formed by tenon joints of four sections of wire, and each section of wire has a quarter-circle section. The cross section of the aluminum tube structure is in the shape of a ring. The aluminum tube structure is made of aluminum.

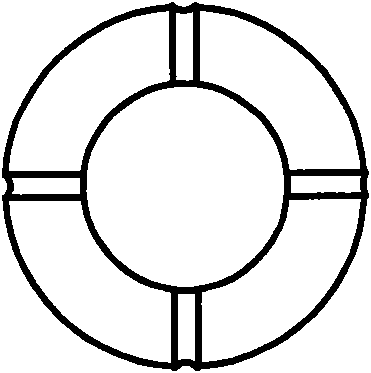

[0010] figure 2 is a schematic cross-sectional view of the aluminum tube structure of the present invention; the aluminum tube structure of an oil-immersed current transformer of the present invention is characterized in that: the aluminum tube structure is in a "U" shape, wherein: the aluminum tube structure The bottom of the "U" shape is wider than the top of the "U" shape; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com