Electric-explosion plasma petroleum yield-increase testing device

A test device and plasma technology, applied in measuring devices, mining fluids, impact tests, etc., can solve the problems of difficulty in establishing plasma channels and low energy conversion efficiency, and achieve the effect of improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

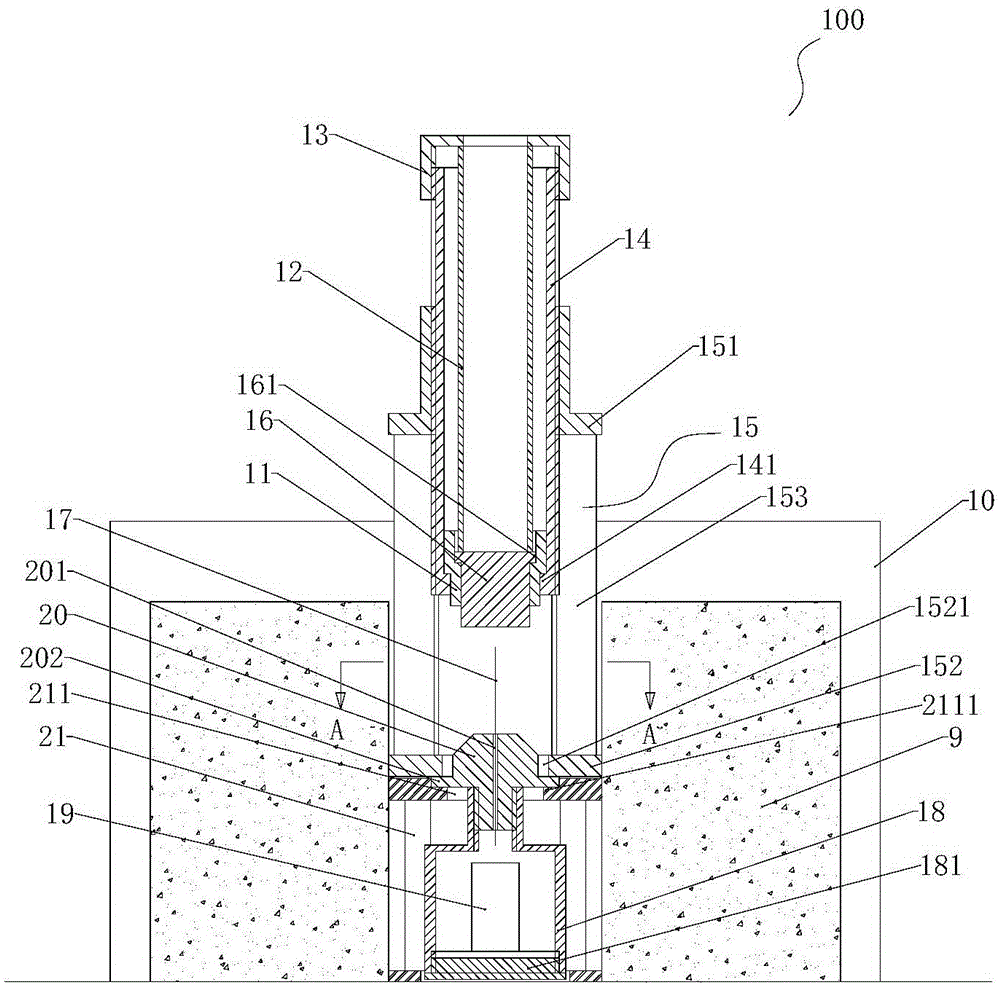

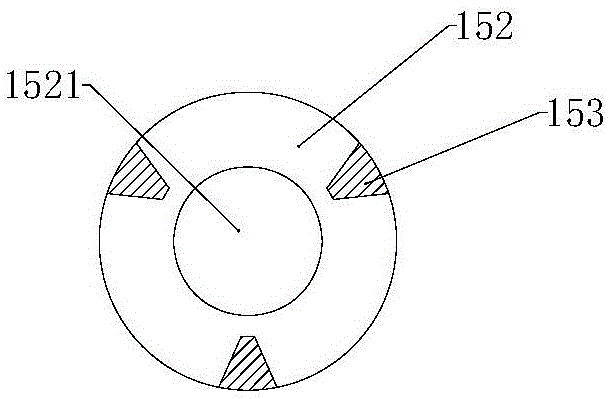

[0040] Such as figure 1 As shown, the present invention provides an electric explosion plasma oil stimulation test device 100, which includes a plasma launch frame 15, an inner sleeve 14, a high voltage electrode 16, a lower bracket 21, a low voltage electrode 20, and a metal shell 18. The top and the bottom of the plasma emission rack 15 are respectively provided with an upper disk 151 and a lower disk 152 with the same diameter, and the upper disk 151 and the lower disk 152 are connected by a plurality of columns 153, which are cylindrical as a whole. A plurality of columns 153 are evenly distributed along the circumferential direction, and a threaded through hole is provided in the center of the upper disc 151 ; the threaded thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com