Kaldo furnace parameter optimization control method based on fuzzy clustering genetic algorithm

A genetic algorithm and control method technology, applied in the field of integrated intelligent control system, can solve problems such as large amount of calculation, many steps, and unsatisfactory system control accuracy and system execution speed, and achieve the effect of speeding up the search speed and avoiding slow convergence speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

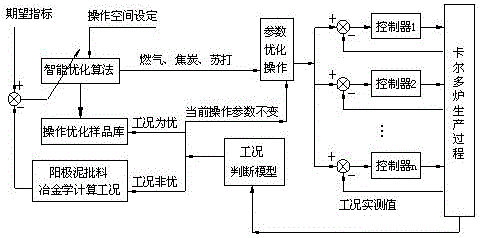

[0037] like figure 1 As shown, the present invention takes the stability of the comprehensive working conditions of the Kaldo furnace as the control target, takes the main factors affecting the Kaldo furnace as the research object, and uses an optimization control method to find the optimal addition of coke powder, soda and gas in order to simplify the algorithm.

[0038] Using the fuzzy C-means clustering genetic algorithm to optimize the addition of coke powder, soda, and gas respectively, compare the optimization results with the actual measured values of the Kaldor furnace and adjust them through the controller, and then adjust the adjusted coke powder, soda , The amount of gas added is judged by the adjustment value of the added amount of coke powder, soda and gas in the working condition judgment model:

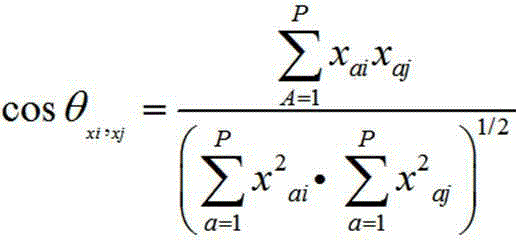

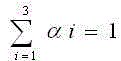

[0039] Since the amount of coke powder, soda, and gas a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com