Inorganic Fireproof Sheath Mineral Insulated Flexible Fireproof Cable

A technology for mineral insulated and fireproof cables, applied in insulated cables, insulated conductors, flexible cables, etc., can solve the problems of increased production cost, poor flexibility, inconvenient installation, etc., and achieves improved electrical stability and overload resistance. The effect of strong ability and convenient installation and laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

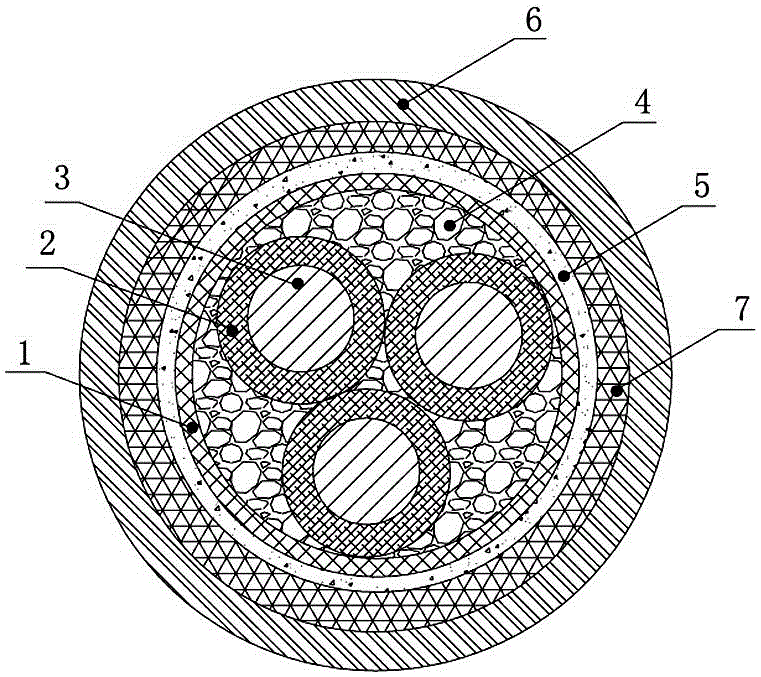

[0021] Such as figure 1 As shown, the mineral insulated flexible fireproof cable with inorganic fireproof sheath according to the present invention includes three wires 3 arranged in the heat insulation layer 1 and wrapped with an inorganic composite insulation layer 2, filled in the inorganic composite insulation layer 2 and the heat insulation layer Inorganic heat-insulating fireproof filler 4 between layers 1, aluminum-plastic composite tape waterproof layer 5 and orange low-smoke halogen-free outer sheath 6 wrapped around the outer peripheral surface of heat-insulation layer 1; located on aluminum-plastic composite tape waterproof layer 5 An inorganic fireproof sheath 7 is arranged between the low-smoke and halogen-free outer sheath 6. The inorganic fireproof sheath 7 is composed of a glass fiber braid wrapped around the outer peripheral surface of the waterproof layer 5 of the aluminum-plastic composite tape, and coated on the surface of the glass fiber braid The mixed mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com