180-degree axial element and processing method thereof

A processing method and component technology, which is applied to the parts of fixed capacitors, the terminals of fixed capacitors, etc., can solve the problems of capacitor damage and difficult processing of two pins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0027] In order to achieve the above object, the present invention adopts the following technical solutions:

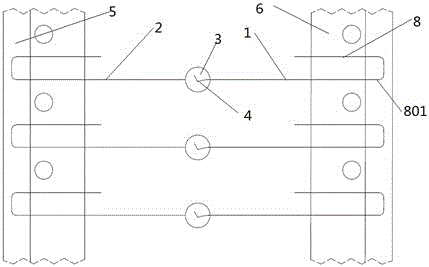

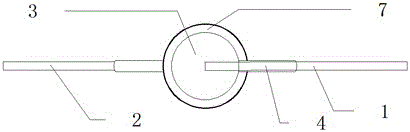

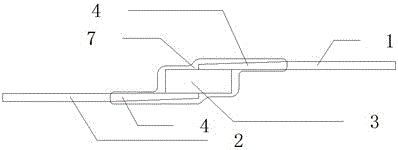

[0028] 180° axial type components, including: the first lead 1, the second lead 2, the fixing assembly that fixes one end of the first lead 1 and the second lead 2, and is set at the horizontal intersection of the first lead 1 and the second lead 2 The chip 3 between the positions; the ends of the first lead 1 and the second lead 2 at the horizontal intersection position are provided with bending hooks 4; the angle between the first lead 1 and the second lead 2 is 180±5°. The fixing assembly consists of: a paper tape 5 for fixing the first lead 1 and the second lead 2, an adhesive tape 6 covering the first lead 1 and the second lead 2 and bonded to the paper tape 5, the first lead 1 and the second lead 2 The U-shaped bent part 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com