High-voltage switch module housing

A high-voltage switch and housing technology, applied in electrical switches, electrical components, circuits, etc., can solve the problems of roughness, inconvenient installation and use, and the surface is not regular enough to achieve high mechanical properties and dielectric properties, good heat resistance and moisture resistance. The effect of good machinability and good machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention includes a bottom plate 1, a side plate 2, a front plate 3 and a rear plate 4 all of which are rectangular plates.

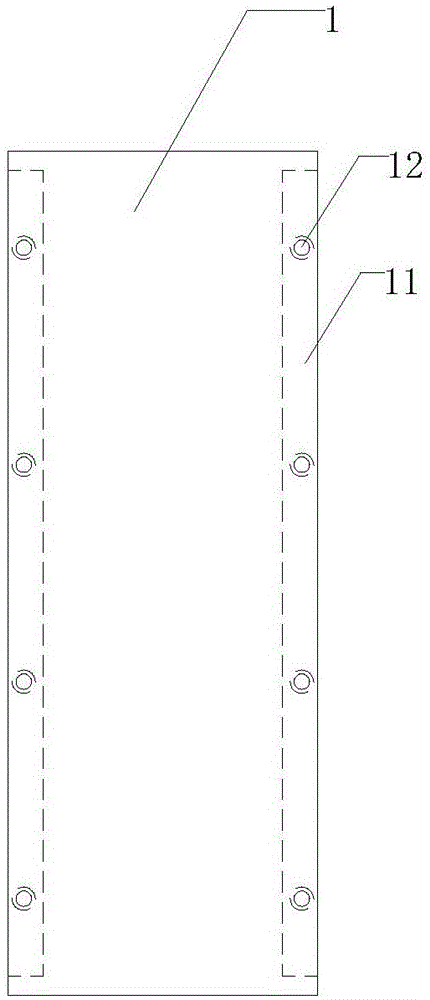

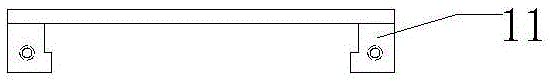

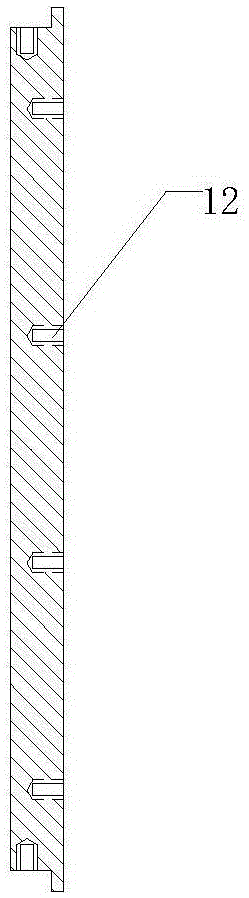

[0019] figure 1 It is a top view of the bottom plate 1 of the present invention, figure 2 It is the front view of base plate 1 of the present invention, image 3 It is a side view of the bottom plate 1 of the present invention. On the plane of the bottom plate 1 , dovetail-shaped edge buckles 11 are arranged on the long sides thereof, and each edge buckle 11 is provided with a row of screw holes 12 .

[0020] Figure 4 It is the side plate 2 of the present invention, and two screw holes 21 are provided on the upper and lower ends of the side plate 2 .

[0021] Figure 5 It is the front board 3 of the present invention, the front board 3 includes a through hole 31, and two rows of screw holes 32 are arranged at the edge of the long side.

[0022] Figure 6 It is the back plate 4 of the present invention, and two rows of screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com