All-round-light LED light source and preparation method thereof

An LED light source, LED chip technology, applied in electrical components, electric solid devices, circuits, etc., can solve the problems of inconsistent specific gravity and properties of phosphors and colloids, poor product consistency, large color temperature deviation, etc., to protect eyesight and achieve consistent color temperature. The effect of improving the sex and increasing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

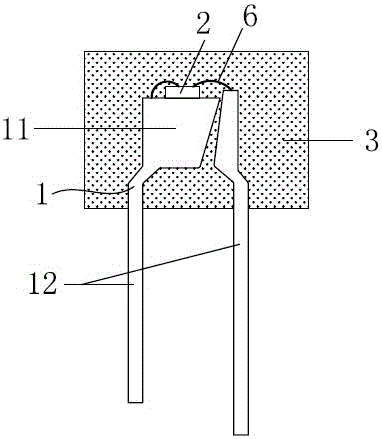

[0031] Such as figure 2 As shown, a full-circumference LED light source includes a pin bracket 1, and the pin bracket 1 is composed of a plane main body 11 and two pins 12; an LED chip 2; a wavelength conversion part 3; the LED chip 2 is welded through a wire 6 is fixed on the plane main body 11 of the lead support 1; it is packaged inside the wavelength conversion part 3 together with the planar main body 11, and the two pins 12 of the lead support 1 protrude from the outside of the wavelength conversion part 3, respectively connected to the power supply positive and negative connections.

Embodiment 2

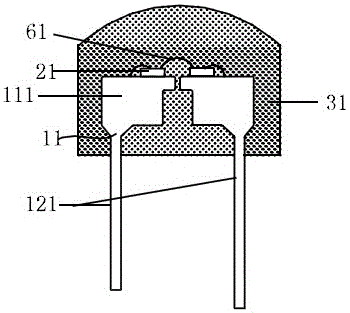

[0033] Such as image 3 As shown, a kind of omnidirectional light LED light source comprises pin bracket 11, and pin bracket 11 is made up of a plane main body 111 and two pins 121; Two LED chips 21 connected in series; Wavelength conversion part 31; LED chip 21 passes through The welding wire 61 is fixed on the plane body 111 of the lead holder 11; it is packaged inside the wavelength conversion part 31 together with the plane body 111, and the two pins 121 of the lead holder 11 protrude from the outside of the wavelength conversion part 31, respectively Connect to the positive and negative poles of the power supply.

Embodiment 3

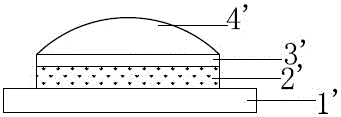

[0035] Such as Figure 4 As shown, a kind of omnidirectional light LED light source comprises pin bracket 12, and pin bracket 12 is made up of a plane main body 112 and two pins 122; Two LED chips 22 connected in series; Wavelength conversion part 32; LED chip 22 passes through The welding wire 62 is fixed on the plane body 112 of the lead holder 12; it is packaged inside the wavelength conversion part 32 together with the plane body 112, and the two pins 122 of the lead holder 12 protrude from the outside of the wavelength conversion part 32, respectively Connect to the positive and negative poles of the power supply.

[0036] It also includes a transparent protection layer 5 covering the outside of the wavelength converting portion 32 . The transparent protective layer 5 is a transparent silica gel protective layer, a silicone resin protective layer or a transparent epoxy resin protective layer, which plays a role in protecting the wavelength conversion part 32 and delaying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com