Method for producing a blind hole in a metallic body

A technology for blind holes and metal workpieces, which is applied in the field of manufacturing blind holes, can solve problems such as no blind holes are found, and achieve the effect of avoiding plastic deformation and precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

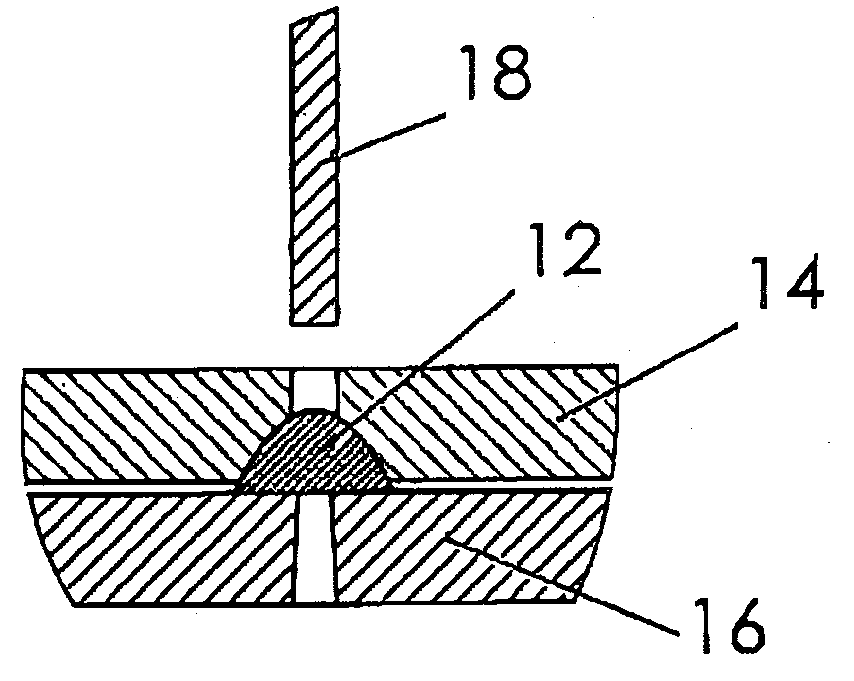

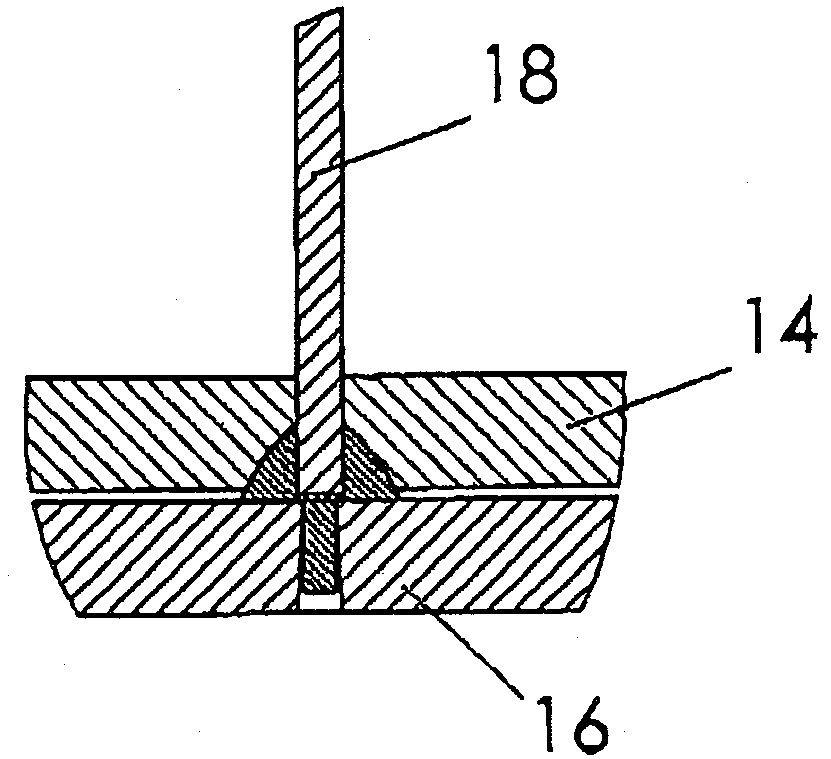

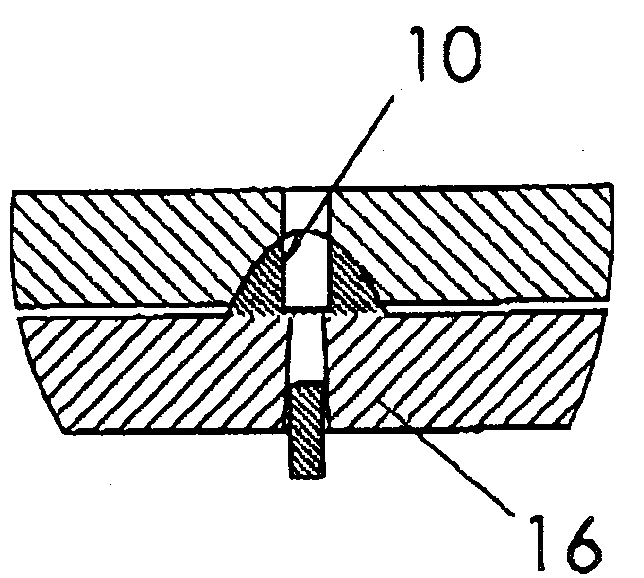

[0027] according to Figures 1 to 4 , the manufacture or method for producing a blind hole 10 in a metal slotted nut 12 with in this case a curved surface will now be described. It is pointed out again that the description of the slotted nut is merely exemplary, since the method according to the invention can obviously also be used and applied to other metal bodies with curved surfaces.

[0028] figure 1 The initial position for the adiabatic movement of the blind hole 10 is shown. In this case, the workpiece 12 , in this case obviously a slotted nut 12 , is accommodated in the holder 14 in such a way that in this case the rounding of the semicircular cross section points downwards. The workpiece 12 to be processed is held on its upper side by a receptacle 16 which has a groove or cavity for the material to be extruded aligned with the punch 18 .

[0029] Thus, the slotted nut 12 or the raw section is secured from the bottom and the top.

[0030] from in all Figures 1 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com