Probabilistic modeling and sizing of embedded flaws in nondestructive inspections for fatigue damage prognostics and structural integrity assessment

一种疲劳寿命预测、探测概率的技术,应用在概率网络、处理探测的响应信号、测量装置等方向,能够解决安全性因素依赖、检测人员不是轻松任务等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

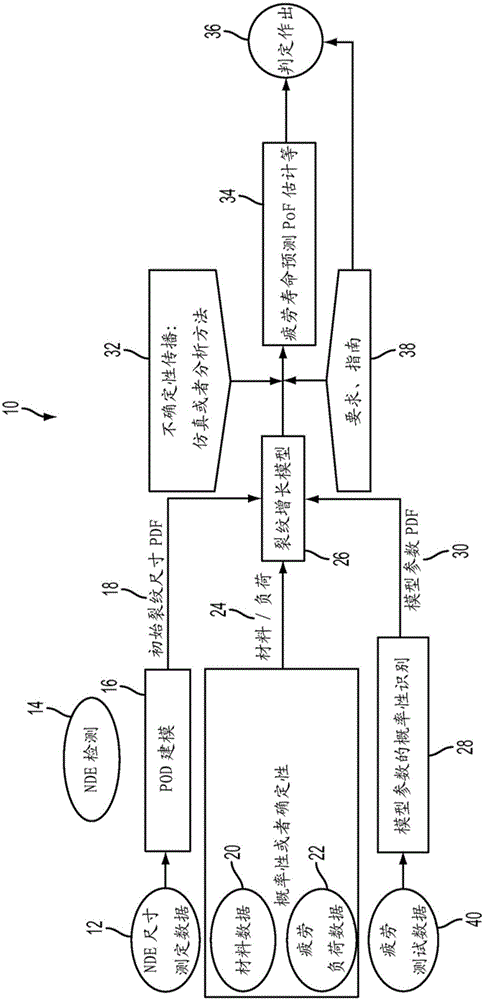

[0022] Exemplary embodiments of the invention described herein generally include a systematic approach to probabilistic life prediction from non-destructive examination (hereinafter "NDE") detection and fatigue life parameters that takes uncertainty into account. While the invention is susceptible to various modifications and alternative forms, specific embodiments thereof are shown by way of example only in the drawings and will be described in detail herein. It should be understood, however, that there is no intent to limit the invention to the particular forms disclosed, but on the contrary, the invention is to cover all modifications, equivalents, and alternatives falling within the spirit and scope of the invention. Additionally, the disclosures of US Patent Publication No. 2013 / 0268214, Application No. 13 / 855,130, titled "PROBABILISTIC FATIGUELIFE PREDICTION USING ULTRASONIC INSPECTION DATA CONSIDERINGE IFSUNCERTAINTY" are hereby incorporated by reference in their entiret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com