An electric heating smoking device that heats tobacco from the outside

An external heating and electric heating technology, applied in tobacco, smoker's products, applications, etc., can solve the problems of small heating area, low heating efficiency and high heating efficiency, and achieve the effect of increasing contact area, high heating efficiency and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

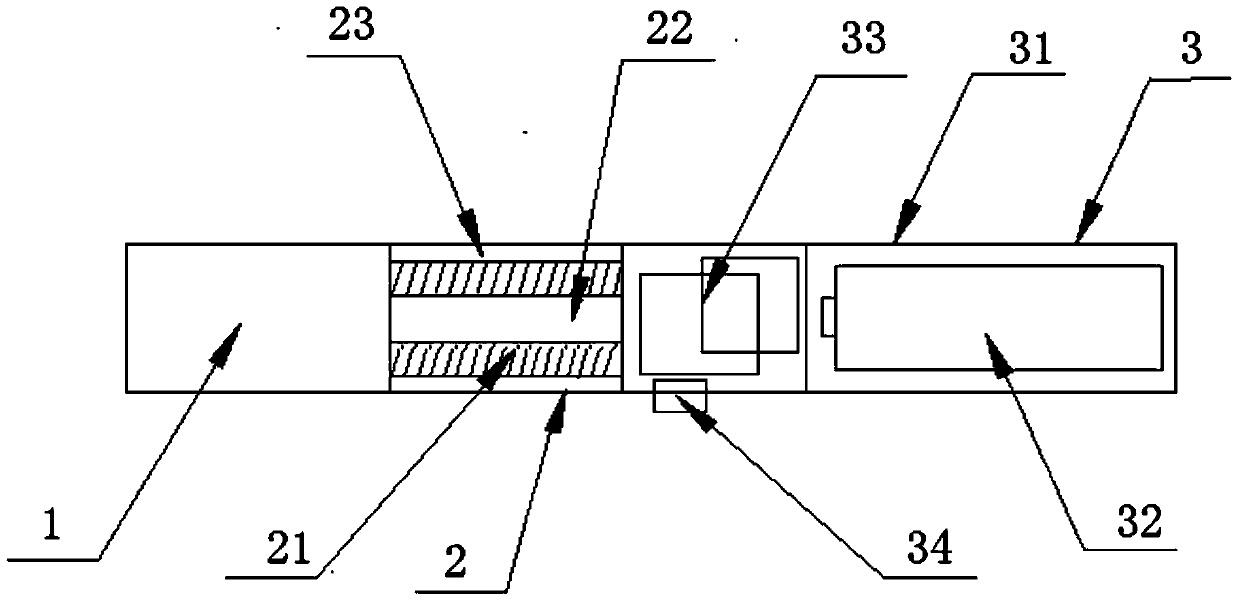

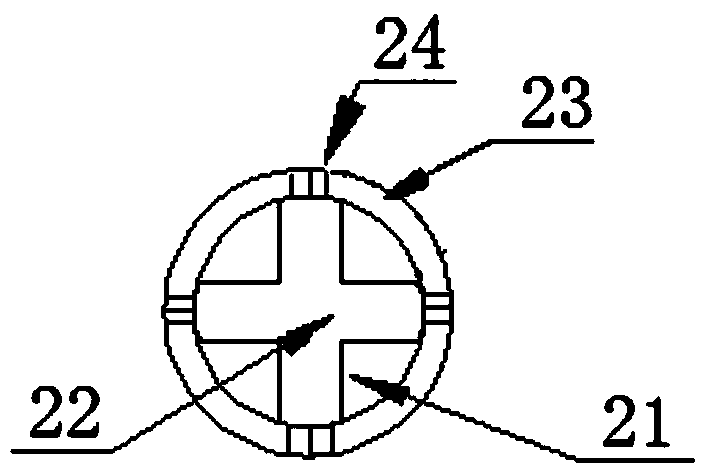

[0016] Example 1: figure 1 and figure 2 An electric heating smoking device is shown, which is composed of a mouthpiece section 1, a tobacco heating section 2 and a power supply section 3. The power supply section 3 consists of a housing 31, a battery 32 and a circuit 33 inside the housing 31, and The circuit switch 34 that is arranged on the outside of the housing 31 is composed of the tobacco heating section 2. The section 1 is connected to the circuit 33, the tobacco filling cavity 22 is located inside the columnar heat source 21 and passes through the columnar heat source 21 in the axial direction, the cross section of the tobacco filling cavity 22 is cross-shaped and the four sides are all connected to the shell 23 , the shell 23 is provided with several ventilation holes 24 communicating with the tobacco filling cavity 22 at the position connected to the tobacco filling cavity 22 , and one end of the shell 23 is fixedly connected with the mouthpiece section 1 .

[0017...

Embodiment 2

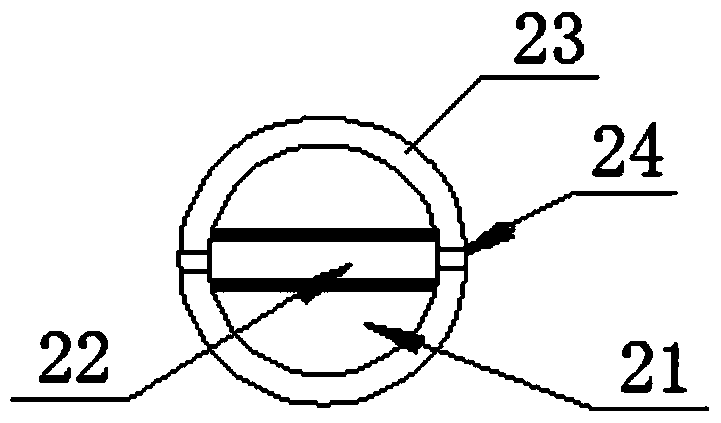

[0018] Example 2: image 3 It shows another electric heating smoking device, the structure of which is the same as that of Embodiment 1, the difference is that the tobacco filling cavity 22 is elongated, and the two sides of the tobacco filling cavity 22 are connected with the shell 23, the The casing 23 is provided with a ventilation hole 24 at a position connected to the tobacco filling cavity 22 .

[0019] Table 1 The results of the evaluation of suction effect test

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com