Novel adsorbent

An adsorbent, a new type of technology, applied in other chemical processes, chemical instruments and methods, etc., to achieve the effect of reducing wastewater treatment problems, high economic value, improving hydrophobicity and the ability to adsorb organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Take an appropriate amount of rice husk and wash away impurities such as sludge with distilled water, then place it in a vacuum atmosphere sintering furnace at 120°C for 12 hours, then mix the dried rice husk with an appropriate amount of HCl solution with a concentration of 1mol / L and put it in In the flask, reflux and condense in a constant temperature oil bath and boil with constant stirring for 3 hours, remove most impurities and filter, wash the filter residue with distilled water until neutral and dry at 120°C for 12 hours, then place the dried rice husk in a vacuum atmosphere Pyrolysis at 500°C for 5 hours in a sintering furnace to prepare rice husk charcoal.

[0018] (2) the rice husk charcoal 30g after above-mentioned pretreatment and the Na that mass concentration is 15% 2 CO 3 The solution was mixed into a flask with a mass ratio of 0.3:1, the flask was placed in a constant temperature oil bath and boiled for 5 hours, then the suspension was filtered, th...

Embodiment 2

[0021] (1) Take an appropriate amount of rice husk and wash away impurities such as sludge with distilled water, then place it in a vacuum atmosphere sintering furnace at 120°C for 12 hours, then mix the dried rice husk with an appropriate amount of HCl solution with a concentration of 1mol / L and put it in In the flask, reflux and condense in a constant temperature oil bath and boil with constant stirring for 3 hours, remove most impurities and filter, wash the filter residue with distilled water until neutral and dry at 120°C for 12 hours, then place the dried rice husk in a vacuum atmosphere Pyrolysis at 500°C for 5 hours in a sintering furnace to prepare rice husk charcoal.

[0022] (2) the rice husk charcoal 30g after above-mentioned pretreatment and the Na that mass concentration is 15% 2 CO 3 The solution was mixed into a flask with a mass ratio of 0.3:1, the flask was placed in a constant temperature oil bath and boiled for 5 hours, then the suspension was filtered, th...

Embodiment 3

[0026] (1) Take an appropriate amount of rice husk and wash away impurities such as sludge with distilled water, then place it in a vacuum atmosphere sintering furnace at 120°C for 12 hours, then mix the dried rice husk with an appropriate amount of HCl solution with a concentration of 1mol / L and put it in In the flask, reflux and condense in a constant temperature oil bath and boil with constant stirring for 3 hours, remove most impurities and filter, wash the filter residue with distilled water until neutral and dry at 120°C for 12 hours, then place the dried rice husk in a vacuum atmosphere Pyrolysis at 500°C for 5 hours in a sintering furnace to prepare rice husk charcoal.

[0027] (2) the rice husk charcoal 30g after above-mentioned pretreatment and the Na that mass concentration is 15% 2 CO 3 The solution was mixed into a flask with a mass ratio of 0.3:1, the flask was placed in a constant temperature oil bath and boiled for 5 hours, then the suspension was filtered, th...

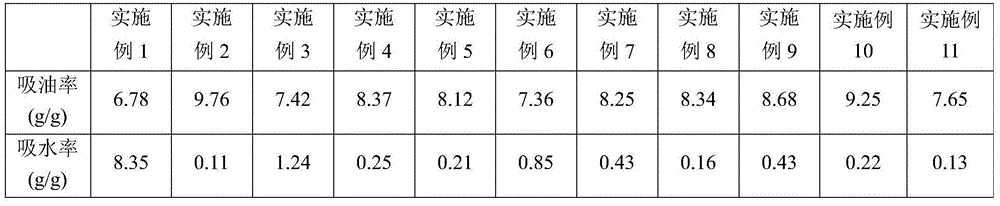

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oil absorption | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com