A hydraulic stretching pad for planetary roller screw driven by AC servo synchronous motor

A synchronous motor and AC servo technology, applied in the field of hydraulic stretching pads, can solve problems such as complex structure, heavy manufacturing workload, and difficult precise control of valve stems, and achieve simple and compact structure, precise blank-holding force adjustment, and low failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

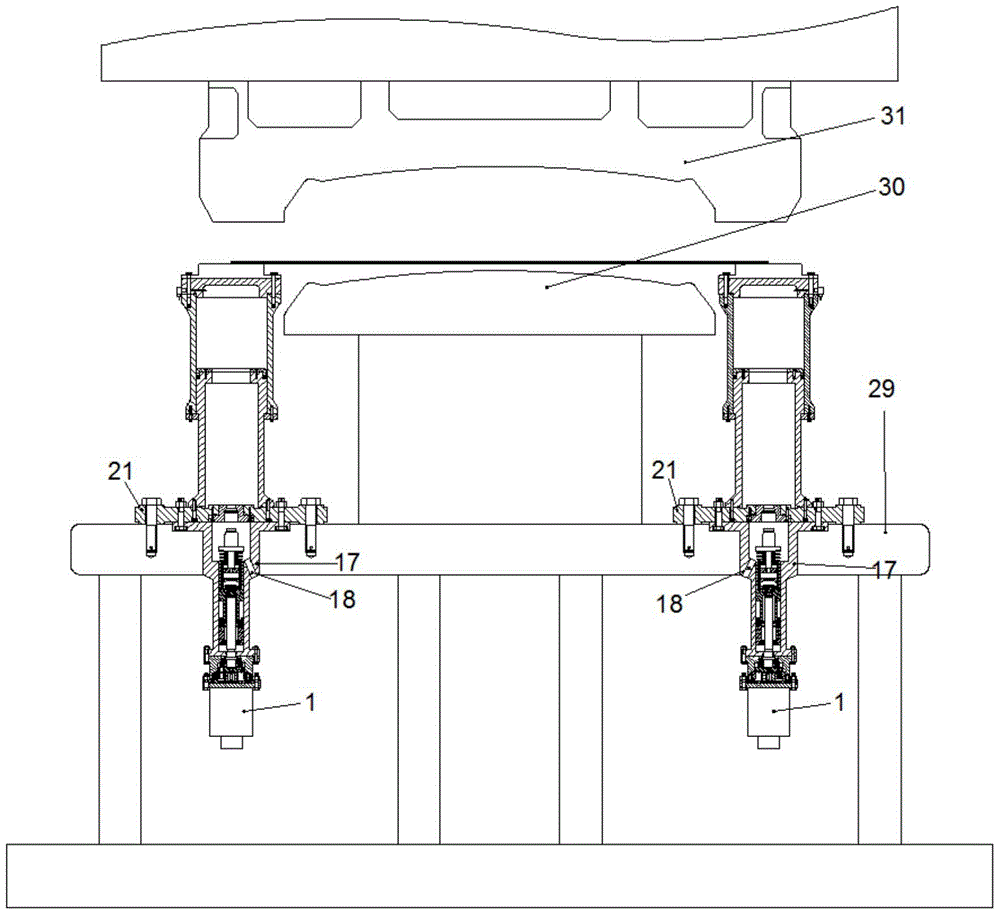

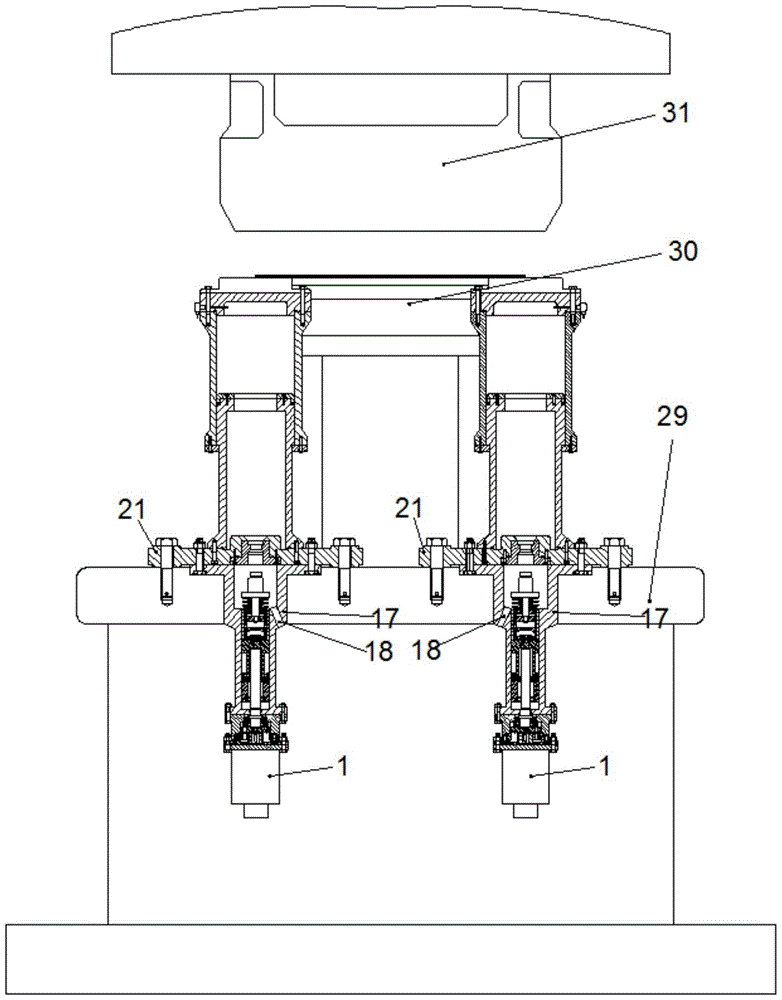

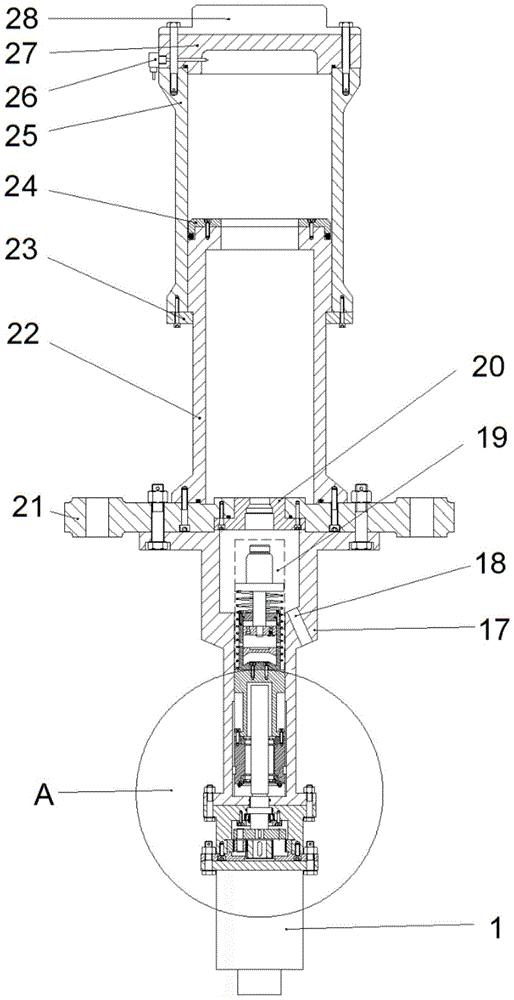

[0018] like figure 1 , figure 2 , image 3 and Figure 4 As shown in the figure, a hydraulic stretching pad for planetary roller screw driven by an AC servo synchronous motor includes four AC servo synchronous motors 1 symmetrically arranged in pairs, and the AC servo synchronous motor 1 is connected to the planetary reducer shell through the end flange 3 7 Fixed connection, the output shaft of AC servo synchronous motor 1 is keyed to the sun gear 2, three planetary gears 4 are arranged in the circumferential direction of the sun gear 2, the planetary gears 4 are installed on the planetary gear carrier 6, and the planetary gears 4 and the inner ring gear 5 meshing, the inner ring gear 5 is fixed in the planetary reducer housing 7 by the end flange 3, the planetary gear carrier 6 is keyed to one end of the planetary screw 8 to ensure synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com