Plane torsion spring device with fault detection and parameter correcting functions

A plane torsion spring and parameter correction technology, applied in the field of robotics, can solve problems such as unseen research results and devices, changes in elastic coefficients, and material fatigue, and achieve the effects of reducing costs, improving performance, and shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further illustrate the present invention below in conjunction with accompanying drawing.

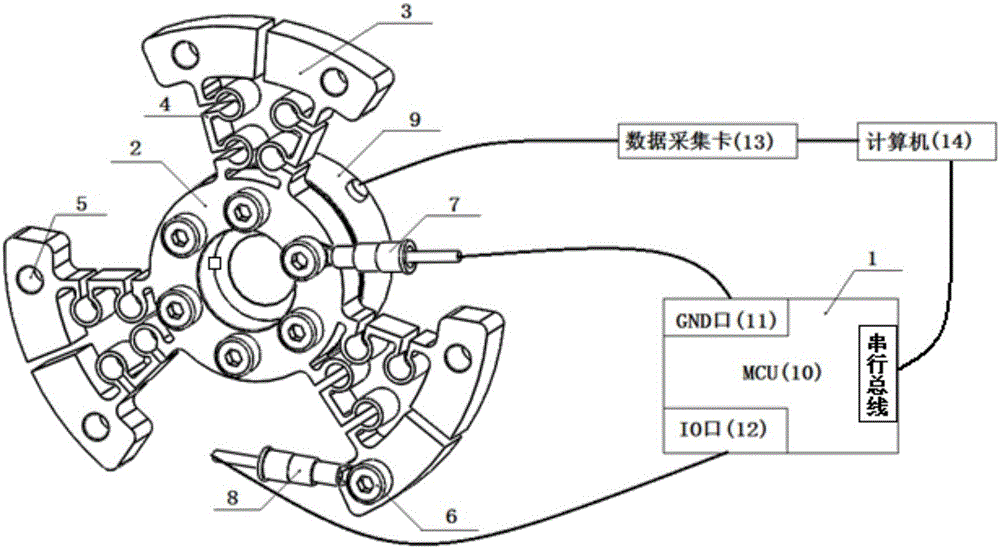

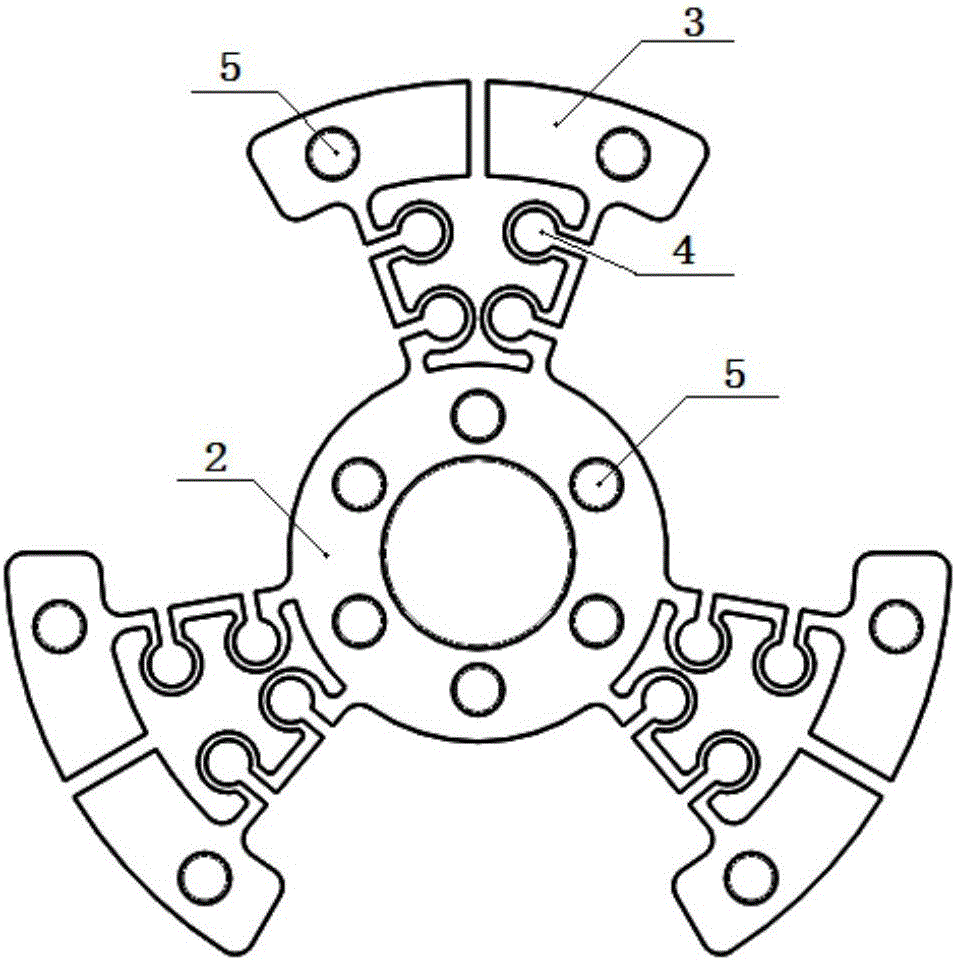

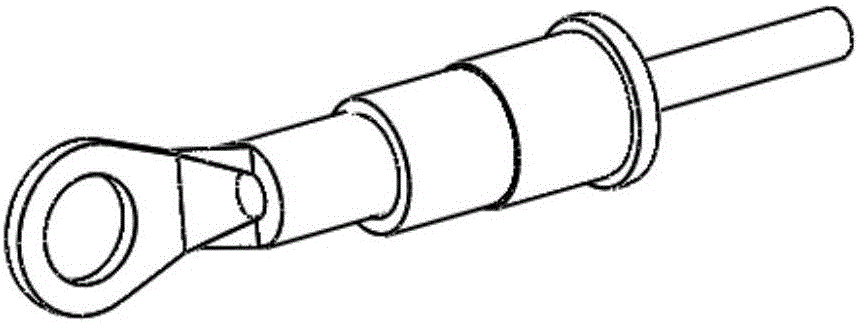

[0017] Such as Figure 1-4 As shown, the present invention has a planar torsion spring device with fault detection and parameter correction functions, which is composed of a planar torsion spring, a fault detection circuit 1 and a torque sensor 9; It consists of a number of elastic bodies 4, wherein the fixing ring 2 and the mounting ring 3 are provided with mounting holes, and the torque sensor 9 and the load end are respectively fixed by screws 6. The fixing ring 2 and the mounting ring 3 are connected by the elastic body 4, and the mounting ring 3 The elastic body 4 can adopt various designs; the fault detection circuit 1 can be MCU10, ARM or DSP, etc., when it is an MCU, the fixed ring 2 is connected to the GND port 11 of the MCU10 through the ground terminal 7, and the installation ring 3 Connect to the IO port 12 of the MCU10 through the signal terminal 8, and the IO port 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com