Paper tube smoothing mill

A fine cutting machine and paper tube technology, applied in the field of papermaking machinery, can solve the problems of easy wear of the cutter, short service life, poor feeding effect of the feeding structure, etc., to prolong the service life, reduce wear and ensure cutting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Combine below Attached picture And specific embodiment, the present invention is described in further detail.

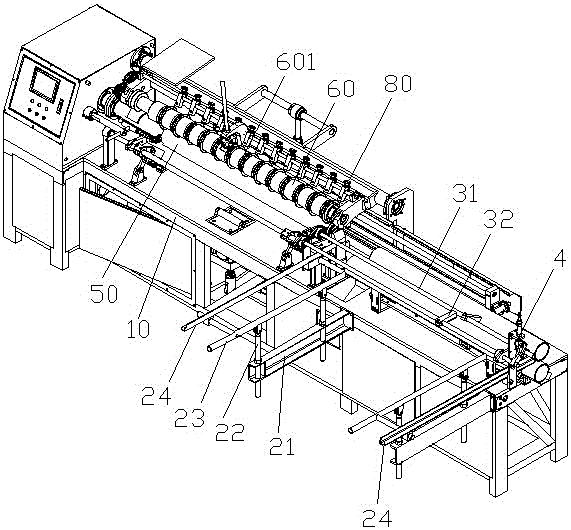

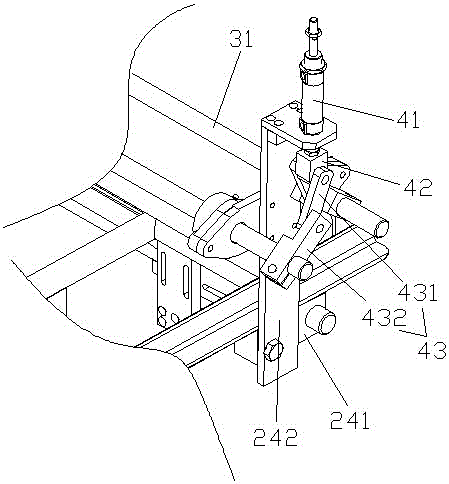

[0019] A feeding structure of a paper tube fine cutting machine, such as attached figure 1 , 2, and 3, including the feeding device, the cutting device and the collecting device for collecting the cut paper tubes which are sequentially arranged on the frame along the conveying direction of the paper tube, the feeding device consists of the front feeding area and the rear The feeding area is composed of the paper tube passing through the front feeding area and the rear feeding area when feeding, and is sent to the cutting device for cutting.

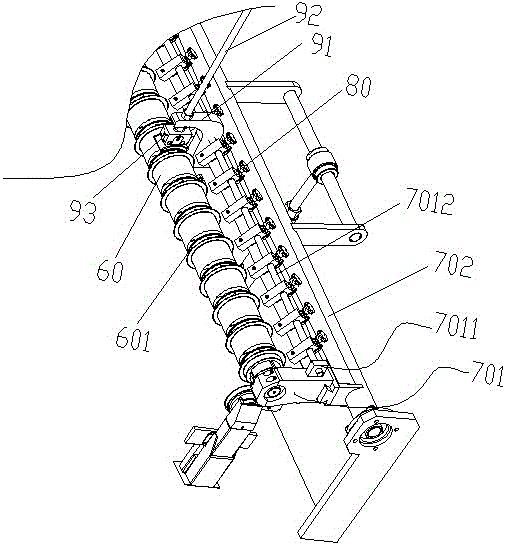

[0020] The slitting device comprises a paper tube shaft 50, a knife roll 60 with a blade 601 above the paper tube shaft 50, and the knife roll 60 is installed on the knife roll mounting shaft 702 through a knife roll frame 701; the knife roll frame 701 is provided with a fixed block 7011, the fixed shaft 7012 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com