Slicing device

A slicing device and blade technology, applied in metal processing and other directions, can solve the problems of high requirements, different depths of knife edges, low work efficiency, etc., and achieve the effect of uniform thickness, smooth knife edge and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

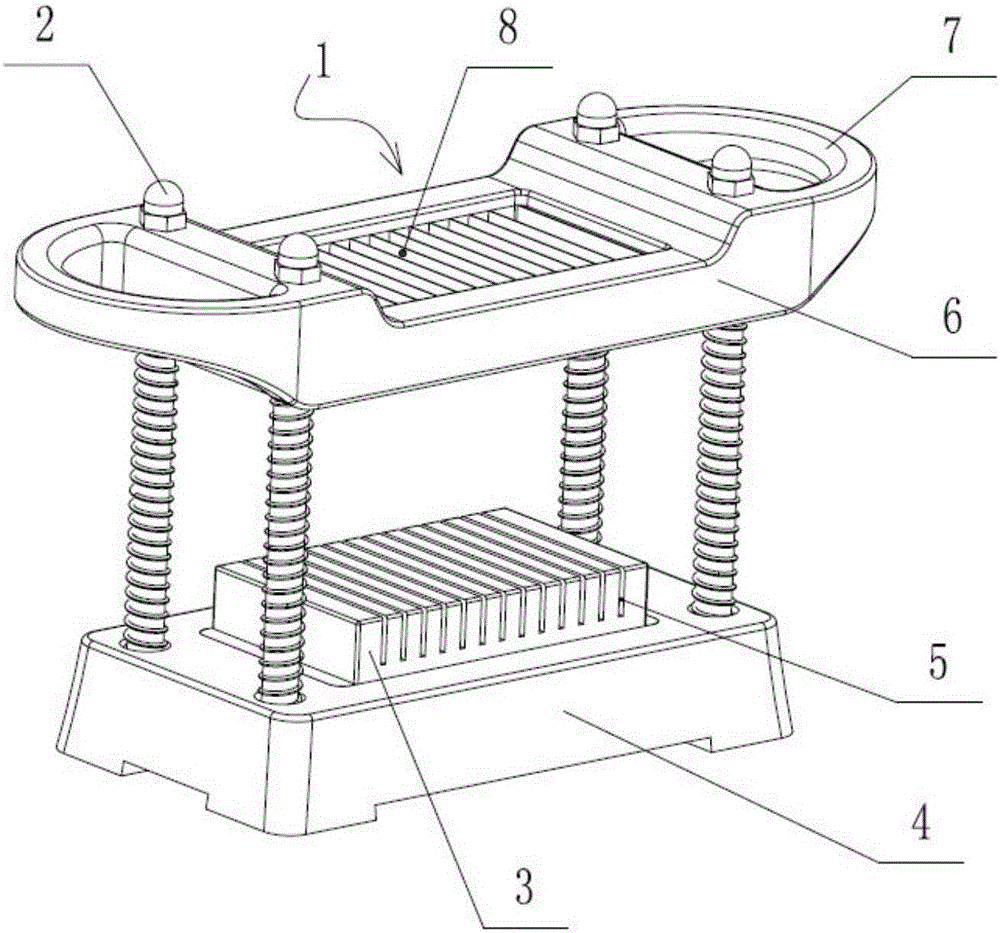

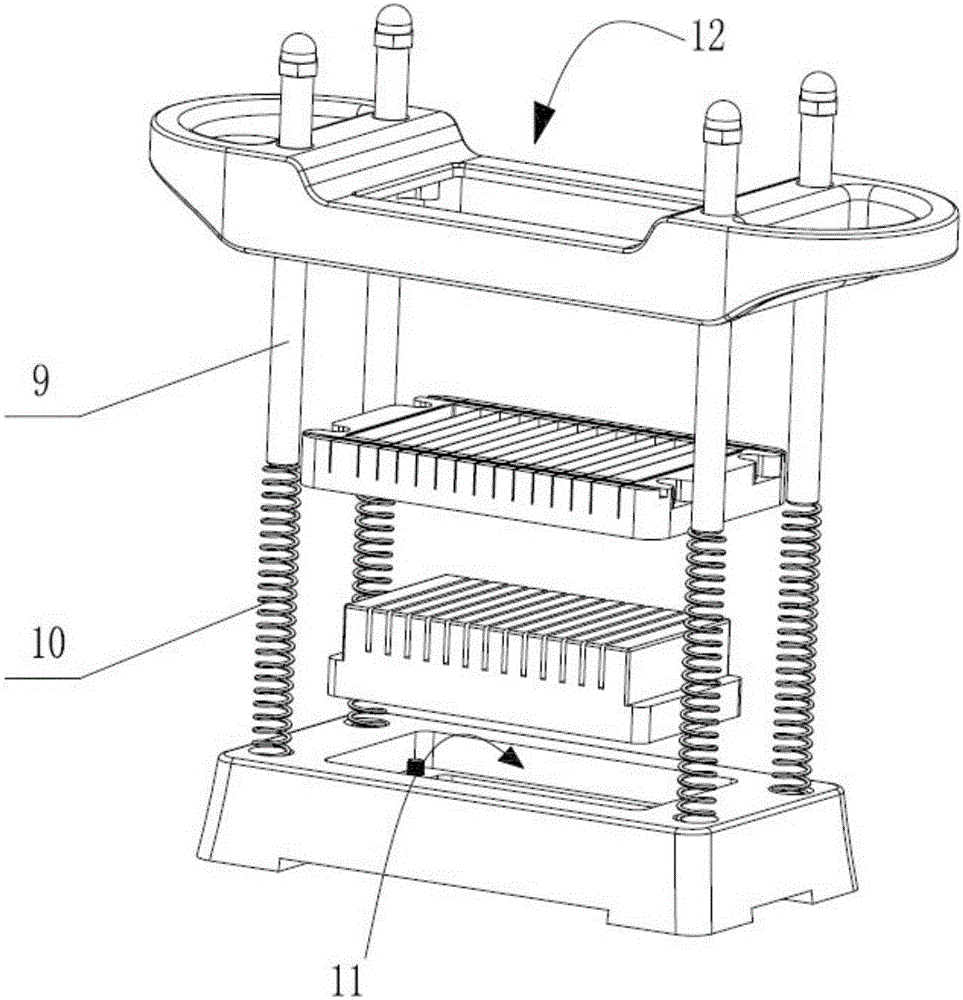

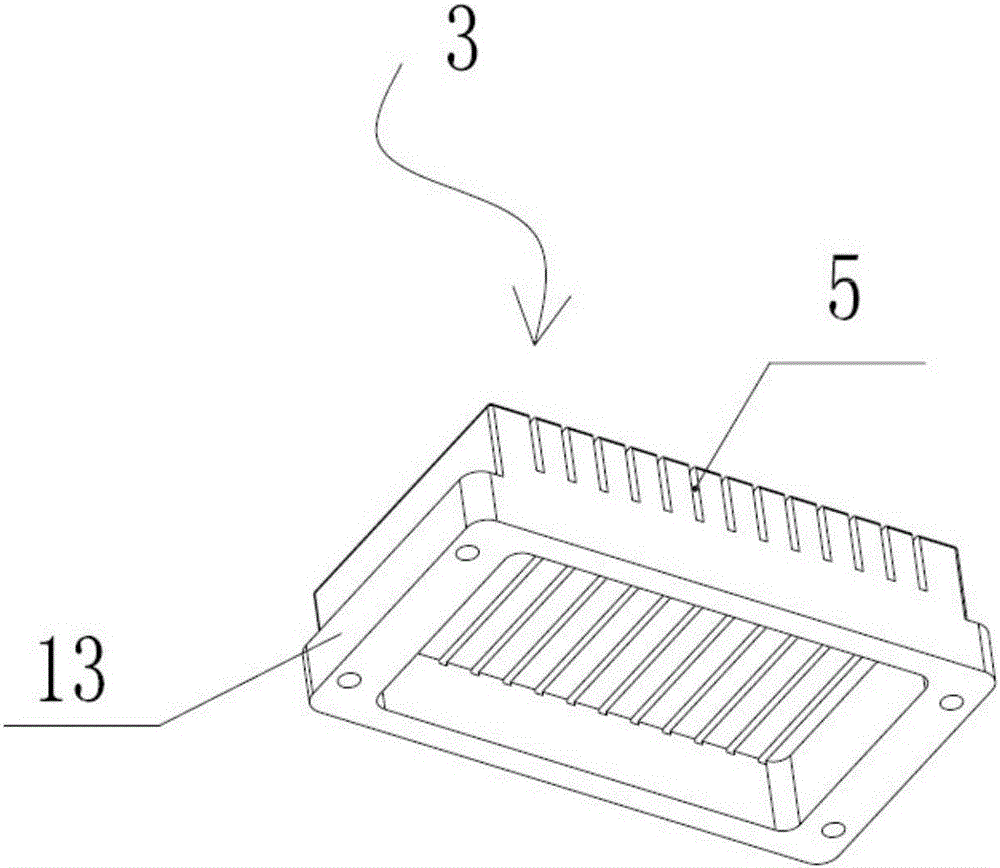

[0029] See Figure 1-5 As shown, a slicing device includes: a lower knife rest 3, the lower knife rest 3 includes a knife groove part, and the knife groove part is regularly provided with 13 knife grooves 5; 13 knife grooves 5 are arranged in parallel, and between adjacent knife grooves The flutes are equally spaced. The knife flute spacing can be set according to the specific requirements of the slice thickness. The blade spacing between adjacent blades 8 is correspondingly set according to the groove spacing. The depth of the groove 5 is greater than the width of the blade 8 . When the upper knife rest 1 and the lower knife rest 3 were fully pressed together, the blade 8 would enter the knife groove 5 completely, so as to realize the interference cutting of the duck blood clot 17 of the article to be cut.

[0030] The slicing device also includes a base 4 on which the lower knife rest 3 is replaceably mounted. Specifically, a first concave cavity 11 is opened on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com